Agriculture

December 22, 2023

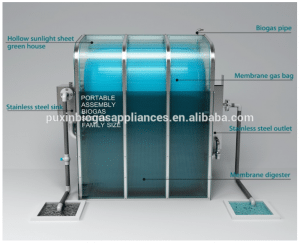

Puxin JZZ2-A13

Read SolutionImplemented by

Shenzhen Puxin Technology Co. Ltd.

Updated on January 21, 2024

·Created on August 25, 2016

Puxin PX-ABS-3.4M3 is a biogas digester that converts organic waste, animal, or human manure into biogas and organic fertilizer.

Puxin biogas system is a family-size digester that converts organic waste, animal, or human manure into biogas and organic fertilizer. The biogas digester is also removable and can be combined with different fertilizer types. The unit is distributed as a Do It Yourself Kit biogas system. The generated biogas can be used for cooking, water heating, and generating electricity. See this video of the product.

Target SDGs

SDG 7: Affordable and Clean Energy

SDG 8: Decent Work and Economic Growth

Market Suggested Retail Price

$850.00

Target Users (Target Impact Group)

Household, Community, Small and Medium-sized Enterprises, Public Sector Agencies

Distributors / Implementing Organizations

Shenzhen Puxin Technology

Competitive Landscape

Direct competitors include HomeBiogas, Sistema Biobolsa, Flexi Biogas BG5, and SimGas GesiShamba.

Manufacturing/Building Method

The biogas digester is manufactured through mass production and the whole product can be assembled by the user without training. The place of production is China

Intellectural Property Type

Patent

User Provision Model

Users can obtain the biogas system on Alibaba. Delivery within 2 weeks after receiving payment. The system is packed in a carton box, ready to install.

Distributions to Date Status

The manufacturers have 2-5 agents that act as distributors as of 2019.Interview with representative.

Design Specifications

Design:

Technical Support

Supported by Puxin. Installation and operation manuals available upon request.interview with representative

Replacement Components

Some of the components replaced by the manufacturer are the feeding pump, circulating pump, and membrane digester.

Lifecycle

Over 10-year lifetime with a 1-year warranty against manufacturing defects

Manufacturer Specified Performance Parameters

This plant was designed to make gas production efficient, be convenient for transport, and easy to install.

Vetted Performance Status

Testing of the product was done by Shenzhen USG Labs, the verdict was that the biodigester is capable of converting organic waste into biogas.

Safety

Extreme caution is necessary when working with biogas. Adequate ventilation, appropriate precautions, good work practices, and adequate personal protective equipment will minimize the dangers associated with biogas. Biogas storage & production bag is made of macromolecular structure polylayer design, therefore there is no leaking risk.

Complementary Technical Systems

Other related products can be added - not included in the unit price: 1. Feeding pump for sewage sludge disposal 2. Circulating pump for raw material feeding and anaerobic digestate mixing 3. Grinder for food waste shredding 4. Electric heater can be added for cold regions 5. Biogas stove, biogas rice cooker, biogas generator, etc 6. Biogass Lamp

Academic Research and References

No academic references.

PUXIN PORTABLE ASSEMBLY FAMILY SIZE BIOGAS SYSTEM. 2016. www.youtube.com.

New Energy Biogas Puxin Professional Biogas Digester System Project – Buy Energy Biogas,Household Small Home Biogas Digester,Biodigester Puxin Biogas System Product on Alibaba.com. n.d. www.alibaba.com.

Domestic Biogas Plant-Shenzhen Puxin Technology Co. Ltd. n.d. en.puxintech.com.

Compliance with regulations

The product has the ISO 12100 certification

Evaluation methods

Each digester will be installed and inspected after manufacturing. Before sending it to Puxin, the factory will conduct a second inspection. Once the product has arrived at the company, the company’s technicians also need to install and check again.Interview with representative

Other Information

Special size products can be manufactured when ordered in batch.

Agriculture

December 22, 2023

Implemented by

Shenzhen Puxin Technology Co. Ltd.

Agriculture

January 20, 2024

Implemented by

Biogas International Limited

Agriculture

January 20, 2024

Implemented by

Sustainable OneWorld Technologies C.I.C. (SOWTech)

Agriculture

January 21, 2024

Implemented by

Mali Biocarburant SA

Agriculture

January 21, 2024

Agriculture

January 21, 2024

Implemented by

SimGas

Agriculture

January 22, 2024

Implemented by

Sistema.bio

Agriculture

January 22, 2024

Implemented by

Tinytech Plants

Agriculture

January 20, 2024

Implemented by

ATEC Biodigesters International

Agriculture

January 29, 2024

Implemented by

QUBE Renewables Ltd.

Have thoughts on how we can improve?

Give Us Feedback