By the numbers, we’ve seen the devastating effect that untreated water can have on developing communities. Worldwide, 2.2 million people die from waterborne illness, and most of them are younger than 5 years old, the World Health Organization reports. Small doses of chlorine can save lives and reduce a disease burden of parasites that keep people home from work and school.

Dosing water with chlorine at a well or stream or wherever it is collected is a low-cost fix for communities that don’t have treated tap water in the home. In communities where women gather water in buckets, however, measuring the proper chlorine dose can be a challenge and a nuisance. In response, a handful of innovators around the world have developed working prototypes of low-cost, automatic chlorine dosers.

Here, we report on some of those designs. Like the designs themselves, this article is a work in progress. We’ll update it as we gather more information.

Ball-valve chlorinator

In rural Kenya and Guatemala, two similar manual chlorine-dosing devices are in use. The non-profit organization Innovations for Poverty Action developed the concept.

IPA’s doser holds a chlorine supply that is protected from the sunlight to keep the chemical from breaking down. The residents place their bucket or jug under a spigot on the device and turn a valve to release a measured dose. The dosers cost $60-90, which, along with monitoring, IPA finances through donations that it collects. According to IPA’s research, people are using them.

Cheaper ball valves

IPA’s device is affordable and effectively doses water at the source. But, apparently, the design could be cheaper and more durable. In 2009, Engineers at the International Development Design Summit in Ghana tested IPA’s design and looked for ways to improve it. They found that IPA’s metal stands rusted and broke down within one year, and that tweaking the valve design could make it cost less.

Instead of metal stands, the IDDS team experimented with bamboo. After three weeks, they found insect holes bored into the bamboo stands. We don’t have longer-term test results, yet.

The IPA device’s valve is an import from the United States and costs more than $20. The IDDS team replaced it with a cheaper, modified PVC ball valve made from locally available materials.

To make it, they glued a 3/8″ sheet of dense rubber to the inside of a normal, 1/2″ PVC ball valve. The rubber sheet divides the valve’s central chamber in half, and each half has a volume of 1ml. Then the team cut off the lock on top of the valve so that the handle can rotate a full 360°. Chlorine in a plastic bag funnels into the valve’s chamber so that each turn of the handle releases about 1ml of chlorine. The DIY valve costs less than $2, plus some elbow grease, the IDDS team reports. Meg Harper, a student at Humboldt State University in California, was on the IDDS team and reported the findings to IPA.

Another member of the IDDS team, Ruben Sanchez-Fernandez, continued to field test the ball valve in Guatemala. He left a prototype in a village and has plans to follow up on its performance, he told E4C.

Now, a third member of the IDDS team, Killian Deku, is producing educational materials about the ball-valve doser in two languages for Ghanaians. Some examples are online: Making Safe Water with Chlorine and Producing Chlorine to Make Safe Water. He makes and sells the devices for communal or private use.

Automatic Level-Sensing Doser

In their field research, the IDDS team saw that people collect water in containers of different sizes. In response, they developed a device that can measure appropriate amounts of chlorine for each quantity of water. They called the prototype the Automatic Level-Sensing Doser. We’ll give a brief explanation of it here. However, it “was a rough prototype, and we’ve since evolved past it,” says Laura Stupin, a member of the IDDS team who is working on a different design, the automatic siphon doser, below.

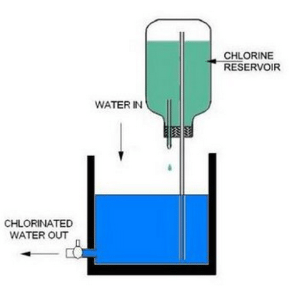

To operate the ALSD, the user pours water from their bucket into a reservoir in the device. A container of chlorine is above the reservoir, and a narrow tube descends from the reservoir’s bottom up into the chlorine container. As the water fills the reservoir, it pushes air up the tube into the chlorine container. That pressurizes the container and forces chlorine out of a nozzle and down into the water reservoir. The chlorine drip shuts off when the pressure equalizes in the container. That way, each dose is tailored to the exact amount of water in the reservoir. The user then turns a valve in the reservoir to drain the now-chlorinated water back into the bucket. The IDDS team’s prototype demonstrated the concept, but it was imperfect, the team reported.

The automatic siphon doser

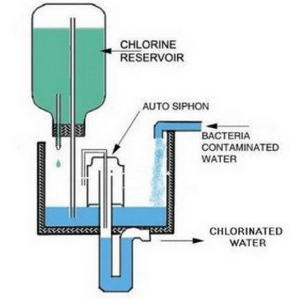

A third design, the automatic siphon doser, draws on some of the same concepts used in the ALSD, but it tries to automate the process even more. It also treats a continuous flow of water so it can work at a borehole. Roughly explained, a user pumps water into the doser’s reservoir, the rising water forces chlorine from a container, and when the now-chlorinated water hits a fill mark, it drains out automatically.

The prototype cost $20 for materials and labor in India. It worked without electricity and had no moving parts except for the chlorine container, which rotated for filling. Each batch was 7.5L of water with 1ml of chlorine, discharged through a 2″ pipe.

Stupin and Suprio Das, who was also on the IDDS team, are applying for a patent for the doser in India. Das is now field testing the device in a village near Calcutta. Until they secure the patent, they won’t offer more details about the device’s design.

Electrified at the source

The IDDS designs require no electricity to operate. But the trade-off is that they need a chlorine supply. In her investigation with IDDS, Meg Harper found that chlorine was usually available in the communities that could benefit from a doser. But, in cases when it isn’t, and just for simplicity, another chlorinator design can make chlorine and dose water with the push of a button. It does, however, require batteries.

The Smart-Electrochlorinator 200 releases table salt into untreated water in its container, then zaps it. The electricity separates the NaCl molecules, producing chlorine. It can treat up to 200L of water and requires a 12-volt battery that can work for 40,000L. The device costs $100 and is in manufacture and field testing now. It is a project by PATH, an international development non-profit organization.