Developing Product Roadmap for Digital Fabrication Platform

BamCore is a company that manufactures bamboo-based structural building components that are sustainable, carbon-negative, and speed up construction. Their unique process converts bamboo into engineered panels that can be used for framing buildings.

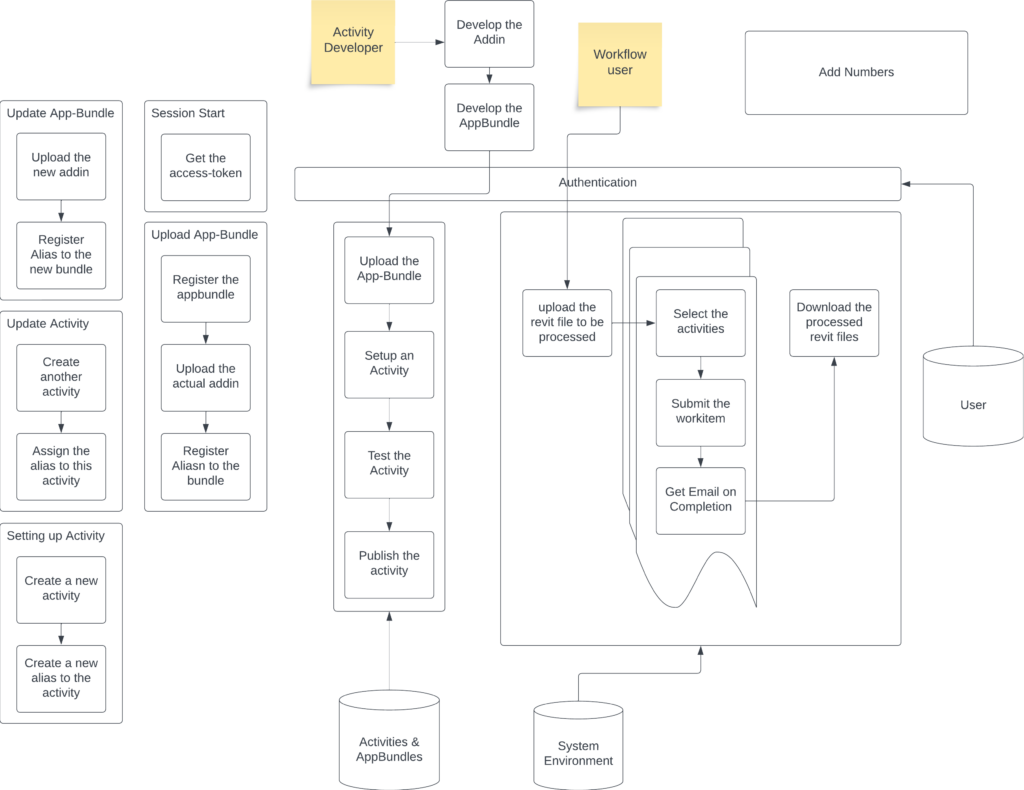

This project aimed to assess the potential integration and automation of their current processes, which involve many manual steps and different software tools. To achieve this, the Fellow investigated the use of Autodesk Platform Services (APS), a cloud-based platform that provides tools and services to connect workflows across different solutions to automate and streamline processes. This would allow for a more scalable process that can take their design models and convert them into fabrication-ready parts.

The Fellow explored the capabilities of APS and developed a roadmap to migrate BamCore’s workflow to the platform. This involved understanding BamCore’s current processes, analyzing cycle times, and identifying key issues. The Fellow also analyzed the available options with APS, including Design Automation API, visualization options, and integration of BIM 360 and Autodesk Construction Cloud for end-to-end data management and internal enterprise resource planning solutions.

The project was divided into multiple phases, with the first phase focusing on the architecture diagram and the project breakdown. By implementing these strategies, BamCore aims to revolutionize the construction industry and make housing more affordable while ensuring energy efficiency, saving time, and reducing labor needs.