The construction sector is the world’s largest resource hog and waste generator. The sector consumes about 40 percent of end-use energy worldwide and emits about one-third of the world’s total greenhouse gasses. That colossal impact stems from the materials used in conventional structures, as well as the geometry and performance of traditional design. To reverse the trend and achieve sustainability, it is important to rethink the theoretical and empirical structural design techniques ensconced in the conventional codes used today. Artificial intelligence may hold the solutions.

While conventional codes have improved structural engineering designs, they don’t necessarily result in optimal structures. Today’s codes barely consider the myriad interactions among design parameters. Artificially intelligent machine learning algorithms, however, are able to design optimum structures by considering existing data based on a large number of parameters. These algorithms predict future scenarios and uncover opportunities for structural improvement.

Machine learning explained

Machine learning is a method of data analysis and a subset of artificial intelligence that deals with teaching computers how to find patterns from available datasets and make accurate predictions, essentially enabling computers to learn and take decisions with minimal human intervention.

In general, machine learning can be classified into three main categories based on the learning process: supervised learning, unsupervised learning, and reinforcement learning.

Supervised Learning is the most basic type of machine learning where the goal is to generate formulae based on input and output values, making use of data that is labelled. In other words, if the machine is learning to recognize dogs, it is shown pictures of dogs and those pictures are labelled “dog.” Whereas, in unsupervised learning, we find an association between input values and group them. In this case, the machine would be shown unlabelled pictures of dogs and cats and it would sort them itself, grouping the photos of animals that have similar characteristics. Lastly, with reinforcement learning, an agent learns through delayed feedback by interacting with the environment through a trial-and-error process. The video above uses the example of a computer learning to play chess. The computer is the agent, the chessboard is the environment, and each move on the board that the computer takes is rewarded or punished depending on whether it is a permissible move or an advantageous move.

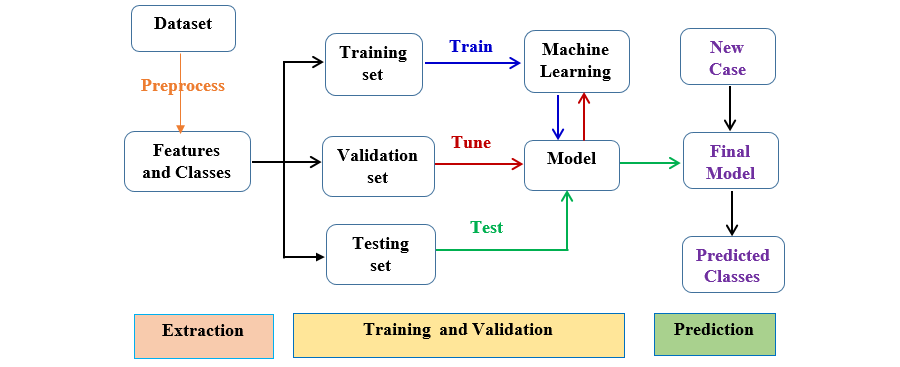

The figure below shows the general experimental workflow of the predictive machine learning model.

Image: JMIR Medical Informatics, June, 2020, Vol 8, No 6 (CC BY 4.0)

Another machine learning revolution?

Structural engineering is concerned with the study and design of load-bearing structures. The use of structural analysis and design methodology requires time-consuming calculations. The engineer must predict how complex structural systems will perform in extreme circumstances, calculating the potential integrity of a structure under stress that is displaying highly nonlinear behavior. For all that math, machine learning can be a viable solution that saves time. As researchers have discovered, the calculations machines can perform are also more accurate.

Though machine learning was created in 1943 and named in 1959, it was not until the 1950s that it came into its own. In that decade, the field became the most prosperous branch of artificial intelligence. Machine learning has continued to advance and now has a wealth of practical applications, including picture and speech recognition, bio-engineering, medicine, advertisement, traffic alerts, and more. Machine learning has grown to be one of the most trending fields in technology today.

Seeing success in so many other fields, structural engineers and researchers have begun to explore the potential for a machine learning revolution in the the design and construction of structures. Structural engineering experts began investigating machine learning applications as early as the late 1980s, but progress was slow due to constraints of accessible machine learning algorithms and computer capacity. A look at the number of publications dedicated to machine learning in structural engineering reveals the importance of the field over time. In 1990 there were no publications, and that number gradually increased to fewer than 20 by 2017. Then, over the course of five years, the number of publications rocketed up to about 130 where it is now (Thai, 2022).

Forty years have gone and we have yet to witness a truly broad acceptance of machine learning in structural engineering, but experts are cautiously optimistic that the time is now. Powerful computers are readily accessible, and we are in the midst of two other revolutions—those of Big Data and the Internet of Things—that contribute to the efficacy of machine learning.

Salient examples in structural engineering

Space trusses are commonly used as roof structures in long-span commercial buildings and canopies. Their design through conventional means and in accordance with conventional codes is most often time-consuming and inefficient. As such, in 1998, Adeli and Park developed and patented a robust and excellent converging neural dynamics model, a machine learning algorithm, which optimizes the design of space trusses by finding the minimum weight design, thus reducing the total cost of construction (US patent 5,815,394, issued on September 29, 1998) (Tashakori & Adeli, 2002).

In 2001 another team used a different machine learning algorithm, artificial neural networks, to forecast the ultimate shear strength of reinforced-concrete deep beams. They found out that the average ratio of real-life to calculated shear strength obtained through the neural network was 0.99, 2.08 through the method provided by the American design code, and 0.85 for the strut-and-tie method favored in the European design code. In other words, artificial neural networks gave a more accurate calculation of shear strength (Sanad & Saka, 2001).

In 2004, researchers performed a similar study and evaluated 176 reinforced concrete beams with artificial neural network. They proved that the average value of the experimental shear strength to predicted shear strength ratios is 1.003. Their conclusion was that neither the American, nor the Canadian, European or New Zealand building design codes correctly estimate the observed shear strength of the concrete beams. With the closest value to 1, the strength values obtained from the artificial neural network are more accurate than those obtained from the empirical equations and theories enshrined in conventional design codes (Mansour et al., 2004). Artificial neural networks provide an efficient alternative design method that yields accurate and optimized results.

Looking beyond conventional materials, researchers have examined sustainable alternatives such as replacing the steel rebar used in reinforced concrete columns with glass fiber-reinforced polymer (GFRP) bars). One research team found that their artificial neural network model is more accurate than the previously proposed models for predicting the axial capacity of GFRP-reinforced concrete columns (Raza et al., 2020) .

These data highlight the usefulness of machine learning as a tool for calculating predictions in situations where standard physics-based approaches used in conventional design codes are too complex, time-consuming, imprecise and expensive, leading to the waste of resources.

Pathway to sustainable design

Due to the nature of machine learning, which requires a large amount of initial data to train the learning algorithm, only some specific fields have benefited from it thanks to their relative simplicity to access huge datasets. The same cannot be stated for fields like embodied and life cycle carbon of building structures where we need to know where the various materials are coming from, the distances they have traveled, the mode of transportation used, the exact construction activities taking place on-site, and so on.

The absence of significant databases of real-world structural designs across the major structural materials is the most pressing issue in this discipline. However, the world is fast moving towards a tech-driven era where data will be readily available and be at the core of transformative innovation, regardless of the discipline.

As such, the availability of big data necessary for the transition from current theoretical design techniques used in many conventional design codes to data-driven design techniques will be an unmissable opportunity for the construction sector to get on track with the sustainable development goals by taking advantage of the automatic multiple interaction checks that can provide machine learning to yield optimized structures with material efficiency and GHG emission mitigation.

It is therefore crucial to call on engineers across the globe to form a fundamental basis of data which will enable quicker transition to a more sustainable built environment. These data can be readily obtained from real-time recording of the behavior and performance of existing structures (data sensing).

Structural engineering needs to step up to be at the forefront of this transformation to provide, through machine learning, optimized designs, cost-effective and sustainable structures.

About the Author

Sonna Donko Maël is a structural engineer based in Cameroon and a former Engineering for Change Fellow.