Automating Component Placement to Increase Process Efficiency

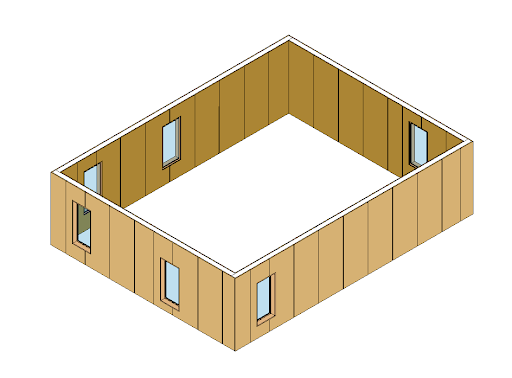

BamCore is addressing the pressing issue of the construction industry’s significant carbon footprint, which accounts for nearly 40% of global greenhouse gas emissions. Their objective is to revolutionize construction with low-cost and carbon-negative solutions. To achieve this, BamCore has developed a three-stage process encompassing material manufacturing, fabrication, and installation. This innovative approach promises faster, more efficient, and environmentally friendly construction, focusing on reducing construction time and labor requirements.

This project aimed to assist BamCore in accelerating construction and increasing efficiency by automating and streamlining their current processes.

The work focused on automating the panelization process, which is currently manual, by up to 80%. By leveraging technologies, including Autodesk Revit, Python, and C#, a Revit plug-in was developed that automates BamCore’s key tasks, including panelizing parts with and without openings, handling auto and manual header reveals, and auto-scheduling panels. This tool allows the team to automatically panelize 84% of parts in an average of 3 minutes, gaining 100x efficiency. Thus contributing to Bamcore’s goal of providing low-cost, carbon-negative construction solutions.