Structural Design and Optimization for Scaling Steel Modular Greenhouses

The objective of this project was to support Kheyti in performing structural works to provide structurally viable and cost-efficient Greenhouses (GHs) to farmers. This would allow them to provide more modular options (reduced and extended versions) of its current greenhouse-in-a-box to assure a year-round income for bottom-of-the-pyramid farmers in India.

After noticing how good their activities have been performing, some farmers (both present and future clients) wanted to experiment with larger greenhouses to expand their activities, while others would prefer smaller ones for nursery purposes. As such, it was necessary to verify the safety of the current conventional GH structure and then perform design and optimization works to obtain optimum engineered dimensions and materials for the pipes, wires, and foundation of various geometries of the reduced and extended GH structures.

The various parts of the conventional GH were extracted from the existing Fusion 360 CAD files and used in Revit for architectural modeling. Then, it was exported to Robot Structural Analysis, where the appropriate loads were applied to perform global analysis; the results were then sent to Fusion 360 for local analysis of the foundations. These structural works helped to assign structurally fit parts to the GHs based on the obtained stresses.

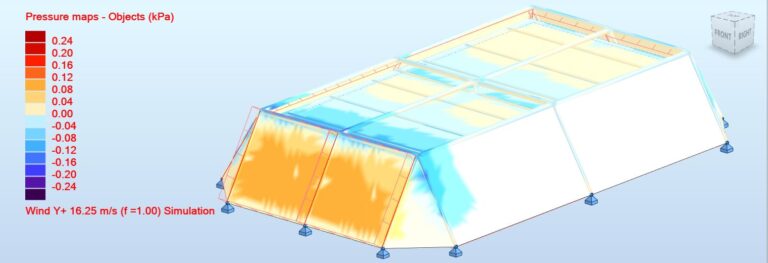

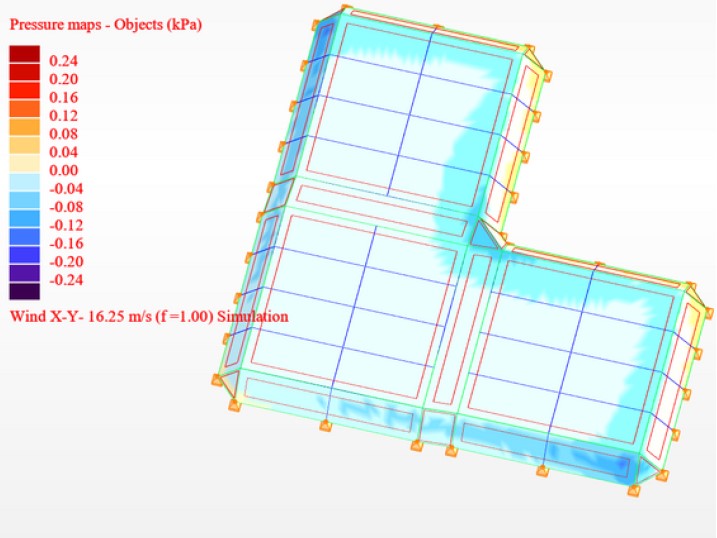

It was found that extending the greenhouses by stacking them together tends to increase the overall safety due to the faces of individual GHs that are being shaded from wind pressures by adjacent GHs. On the other hand, extending by structurally linking the GHs has to be studied case by case but has a tendency to provide safety. The latter option was chosen as it comes with reduced material quantity, thus ensuring cost efficiency. Also, the reduced greenhouses were all safe, with the least being the 1/4 GH version. While ensuring safety, cost optimization will be achieved by using lower-strength pipes and/or 5mm balcony cables.

Diagonal wind pressure distribution on 3 stacked greenhouses (3GH Model) Attribution: Sonna Donko Maël