Development of a Solar Pump Electronics Design Use Case for Training

The objective of this project was to give the KickStart International product design and development team an end-to-end understanding of the electronics design through a process workflow that can be adopted for future internal training. This is a significant skill set for the KickStart team as the organization looks into upgrading the manual pumps to solar-powered pumps. The project was implemented in Nairobi, Kenya, where KickStart International’s engineering and product intelligence center is situated. The project involved both physical and virtual engagement for a duration of five months with 5 team members from KickStart International.

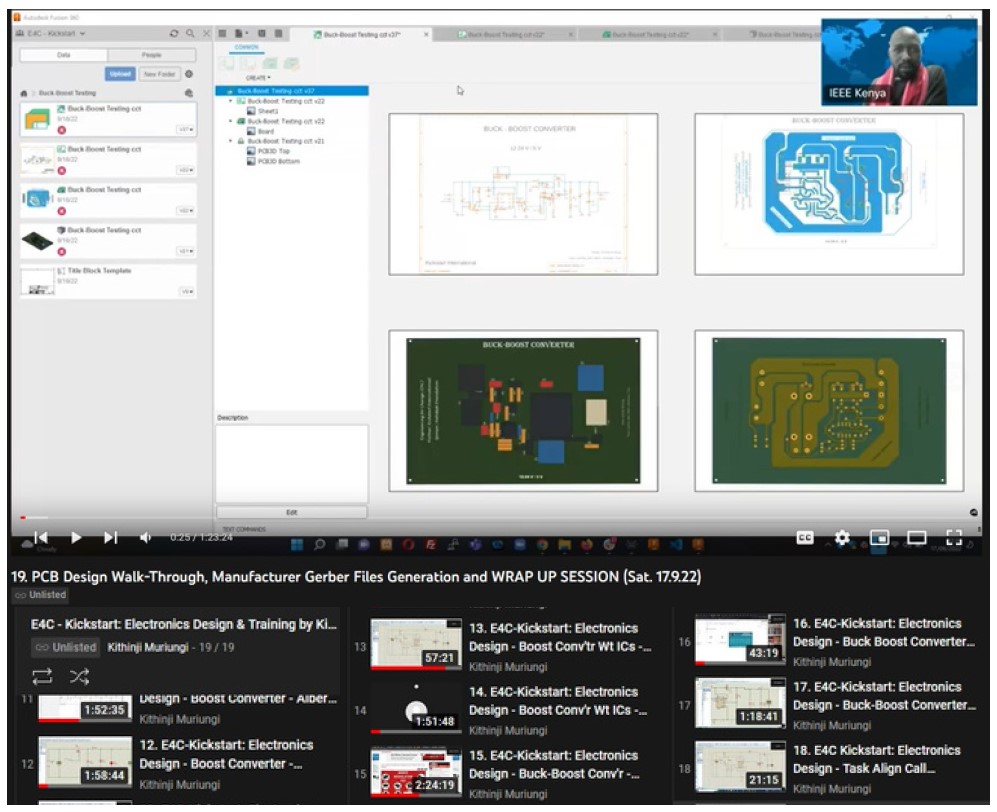

The project scope included theoretical presentations and open-team discussions, hands-on practicals and demonstrations, individual and team circuit design exercises, and an industrial visit to an electronics manufacturing facility. The virtual sessions happened every week on Monday and Wednesday and 2 Saturdays per month, which were divided into one virtual and one physical. The sessions ranged from 1 to 4 hours. Each session followed a step-by-step outline, and all the sessions were recorded and shared on YouTube for future reference. The electronics design and training delivered content included: introduction to electronics engineering and design; basic electronics circuit understanding and configurations; fundamentals of solar electronics systems; electronics circuit design and simulations tools (Autodesk Fusion 360 Electronics and Proteus) understanding circuit design workflows; individual and team basic circuit design (Buck, Boost, and Buck-Boost Converter); basic circuit assembly (breadboard and stripboard); PCB design; Manufacturer files generation (Gerber files); and electronics manufacturer industrial visit at Gearbox Europlacer.

The step-by-step build-up and iteration of the training material through regular feedback and customization based on the KickStart team’s needs and use of both Autodesk Fusion 360 Electronics and Proteus brought a holistic delivery of both theory and hands-on learning. At the end of the project engagement, all the KickStart International design team members were able to understand the end-to-end process workflow involved in electronics design and development.

Virtual Sessions recordings on YouTube, Attribution: Kithinji Muriungi