Icepoint Mechanical Vapor Recompression Compressor Aerodynamics Efficiency

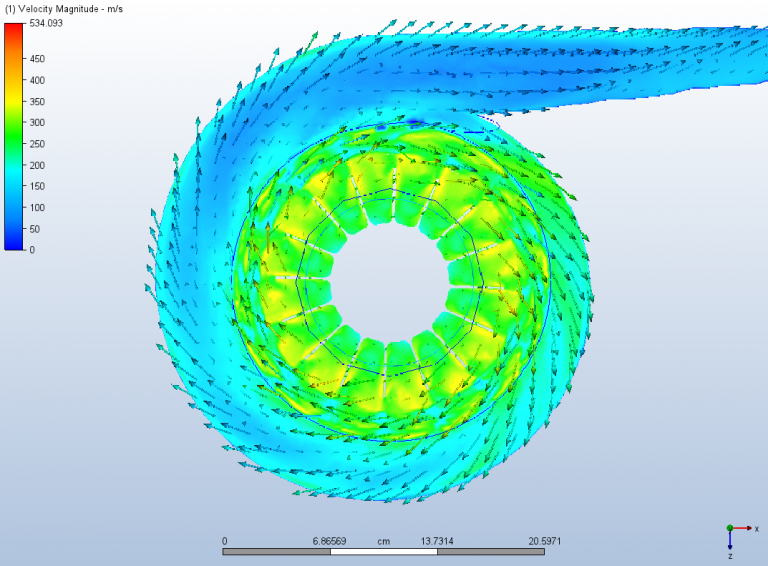

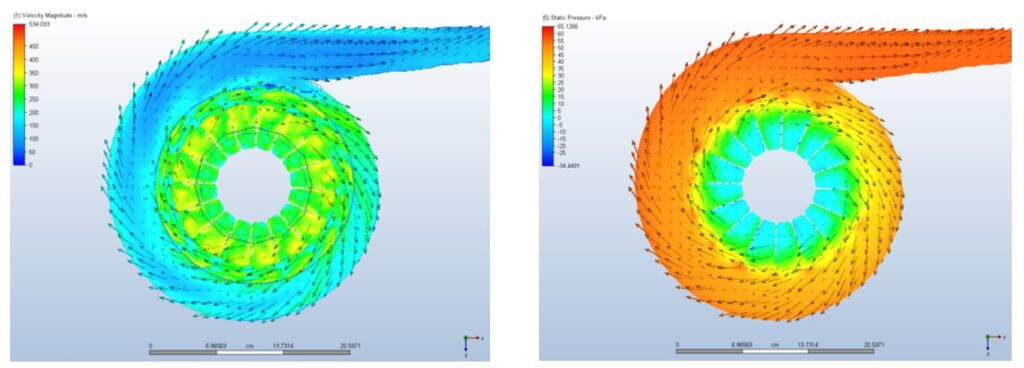

This project provided Rebound Technologies with a computational fluid dynamics (CFD) simulation of the baseline aerodynamic performance of the compressor used in their Mechanical Vapor Recompression (MVR) system.

Rebound Technologies has performed lab tests to determine the operating ranges of the compressor being implemented in their MVR system, but this project aims to establish the theoretical performance of this compressor using the software package of Autodesk CFD and determine if improvements can be made to the design. The work focuses primarily on the current operating parameters being implemented in the system as well as the current volute and impeller geometry.

A geometry assembly file was constructed to be imported to the simulation environment. The current impeller and volute geometry were used as the basis to construct the domain geometry where the flow path was simulated. Research and trials were performed to determine the parameters, conditions, and flow material in the simulation environment that could ensure the highest fidelity and accuracy of the simulation with respect to the behavior of the real system.

A record was developed on how all these parameters may interact with one another and what considerations must be taken into account when applying them. A CFD model file was produced so that the partner organization could continue testing different conditions in the simulation environment.

Rebound Technologies aims to provide a new refrigeration technology that not only is able to provide more flexibility to end-users, which can lead to massive reductions in energy consumption but also to provide a system that doesn’t require the use of potentially hazardous refrigerants used in traditional, industrial refrigeration systems such as ammonia. The improvement of the MVR compressor can lead to further improvements in the energy efficiency of the system.

Pressure buildup (top) and velocity profile (bottom) in a cross section view of the compressor, Attribution: Gabriel Ayú Prado