EDITORIAL TEAM: Zoé Bezpalko, Autodesk D&M Sustainability Strategy Manager; Erin Peiffer, E4C Expert Fellow; Mariela Machado, E4C Program Manager; Grace Burleson, E4C Research Manager

The United Nations defines sustainable development as “development that meets the needs of the present without compromising the ability of future generations to meet their own needs.” This approach requires three core elements of sustainability: economic growth, social inclusion, and environmental protection. There are ample applications and opportunities for design and manufacturing (D&M) solutions in each of these core sustainability elements. D&M simulation tools, such as computer-aided design (CAD) are designed to improve the efficiency of manufacturing, saving time, energy, and reducing material usage and waste.

Traditionally, D&M solutions emphasized saving companies time and money, however there is an increasing emphasis on their role with sustainability goals. With increasing pressure from consumers and government, the D&M industries are currently experiencing considerable market shifts. There is an emphasis on producing more, with less negative impact in order to meet market demands while mitigating emissions and pollution levels and meeting the goals of sustainable development. This research collaboration between Engineering for Change and Autodesk aimed to assess the main drivers for industry interest in improving product sustainability.

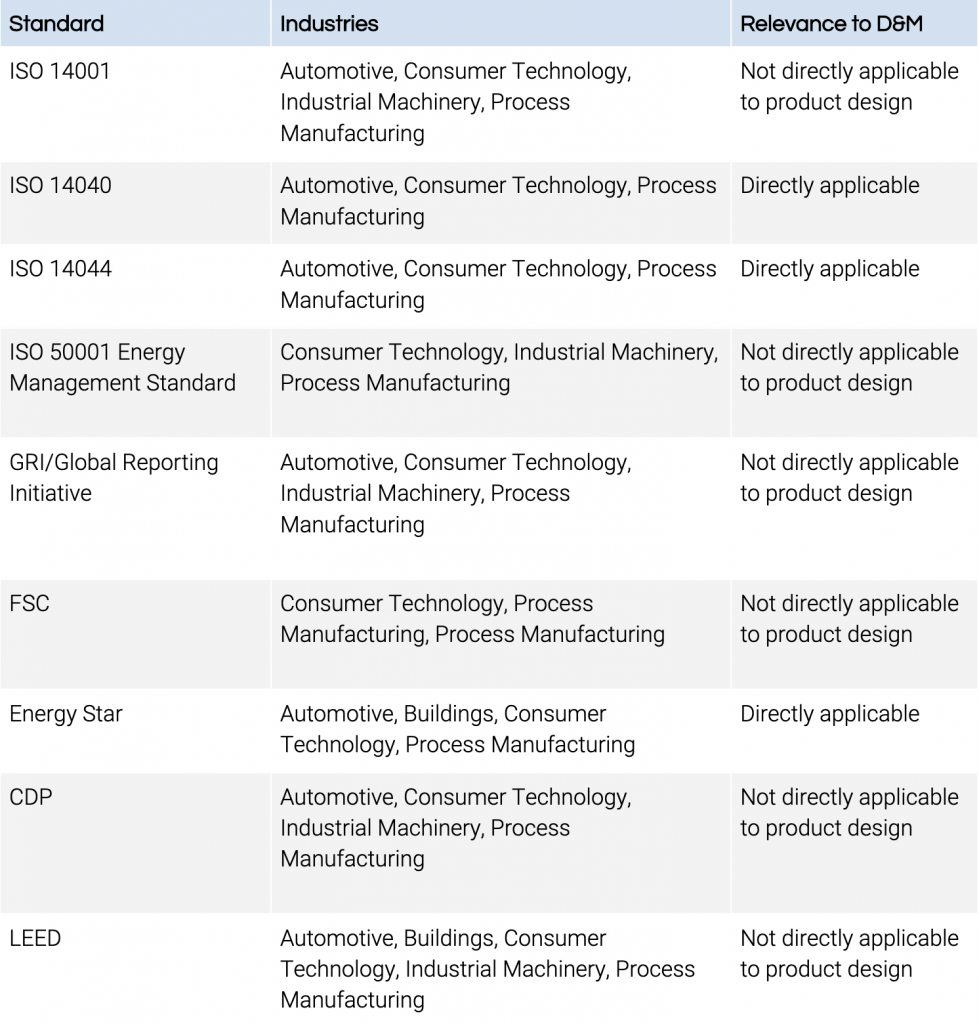

Top Standards and Certifications in Product Design and Manufacturing

Sustainability standards that are relevant to design and manufacturing, highlighted in Table 1, are derived from the International Trade Center’s standards list, the UNFSS Report, the EU Sustainable Production and Consumption’s publications, and top companies’ publicly-facing sustainability reports, focused on four target industries: Consumer goods, Automotive, Industrial machinery, and Process manufacturing industries. Notably, two standards are most relevant to design and manufacturing were 1) ISO 14040/44 and 2) Energy Star. From further inspection of these standards, combined with insights from interviews with key experts, Energy Star Specifications were found to be the most commonly cited, and its specifications were most closely aligned with product design.

Table 1: Top shared certifications in consumer goods, automotive, industrial machinery, and process manufacturing industries.

Company-Specific Trends

In addition to third-party standards, there is trend of companies creating custom, self-managed and self-declared standards and programs to meet sustainability commitments. Some prominent examples include:

- Amazon: Shipment Zero Program to make 50% of all Amazon shipments net zero by 2030.

- Apple: Zero Waste Program at their 450 corporate facilities, 500 retail stores, and 5 data centers.

- Nestle: Zero Waste to Landfill standard.

Motivation for Increasing Sustainability Initiatives

To assess the growing industry motivations for sustainability, eight experts with relevant experience in D&M industries (both industry and academia) were interviewed.

Social Movements and Values

Social movements and shifts in cultural values can drive companies to respond to growing demand and progressive action. Increased pressure to have positive sustainable impact can drive a move towards sustainable practices and that concerns have been moving further up the supply chain in recent years, including responsible sourcing of raw materials, labour and fair wages at all stages. Concerns are also motivated by current environmental and climate related events which act as a reminder of what is at stake. Those in academia and industry suggested that more sustainable company values can be influenced by fiscal incentives and customer demands. One interviewee stated that for real change to happen, you need to have behavioral scientists doing research on how to motivate societal value/behavior change, not just engineers.Interview with expert

Regulations

Regulations were cited by industry and academic representatives as key drivers in sustainability initiatives. Companies are motivated by wanting to keep up with legislation as otherwise they face liability with potential financial consequences. In addition, the need for enforcement of regulations to ensure compliance was highlighted as an area with room for improvement. International companies may also be driven to adhere to the strictest regulations in the world to avoid a patchwork of standards over the countries in which they operate.Interview with expert The response to regulations can be tied into customer demand, with one industry/academic interviewee suggesting that without client or customer demand, the response to increased regulation is intense lobbying.Interview with expert

“Regulations first create positive action, and then the type of action depends on the customer and cost.”

Customers and Consumers

Customers, representing businesses at the next stage in the supply chain and final consumers, have the ability to put pressure on businesses to provide more sustainable products. One industry representative working with companies seeking voluntary sustainability certifications cited their biggest motivation as customer demand. This was echoed by another expert who cited customers and competitors as the main way to increase implementation of sustainable practices. Customers now question suppliers on how they plan to offer more sustainable products and this can carry all the way down the supply chain. Industry leaders can have huge leverage on their suppliers and the business to business interaction can be even more impactful than consumer interaction. As both industry and academic experts stated, it can now put companies at a competitive advantage to claim sustainability certifications and it is something they advertise to win contracts.

“Companies advertise this, it’s part of how they win contracts – ‘we will make your jeans, we will make your t-shirt, we are a LEED Platinum factory’.”

CEOs and Management Roles

One of the internal drivers for change that interviewees identified was CEO and management influence. CEOs, who bring knowledge and values from other companies or come with personal environmental goals, may make the decision to take businesses in a more sustainable direction. As described by one academic expert, the design system is not just CAD but involves Enterprise Resource Planning systems and accounting systems that feed into each other, and with upper management having influence over product decisions and company direction, they play an important role. Interview with expert

“I had a CEO come to see me a few months ago, and he said that 2 weeks previously he was driving his daughter to school when she asked ‘Dad, what are you doing about climate change?’

If you can go home from work, and tell your daughter ‘I am working on a program to reduce the energy to make this bottle, and that will save more energy than a street of houses’, that makes heroes of people in front of their children.”

Sustainability Functions

Academic and industry representatives reported standards and initiatives being identified by the sustainability functions, generally with endorsement from upper management and manufacturing functions. Manufacturing leads often run waste reduction initiatives although according to interviewees this is often driven by efficiency and cost savings. Some sectors, such as biomedical, will also rely on input from regulatory functions to ensure legal compliance.

Engineers and Designers

Once standards have been identified, according to both academic and industry representatives, more often than not, designers will have little visibility of the individual standards and will receive their direction instead through the design brief. In addition to this, one industry expert stated that designers and engineers generally do not consider their products solely on the sustainability impact, but on the cost and efficiency instead. Although they may not have visibility of sustainability initiatives, it was acknowledged by most experts that designers can control environmental impacts related to material selection, size, geometry and manufacturing considerations.

This research was completed as part of the 2020 E4C Fellowship program. Learn more about the Fellows who worked on this research collaboration by connecting with them on LinkedIn: Elizabeth Collins, Danna Xue, and Erin Peiffer.

No Comments.