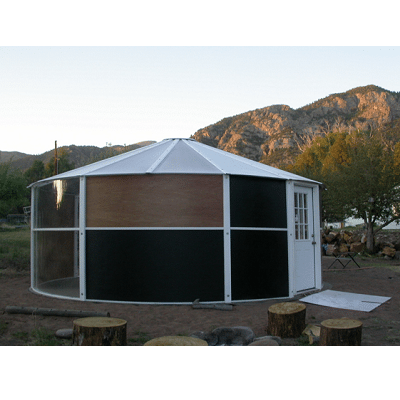

Product Description

circHouse is a prototype for a modular yurt structure that can be constructed using local plastic or wood paneling to produce a transitional shelter. It aims to be durable, with rapid deployment to answer to a number of needs, either humanitarian or logistical. All roof and wall panels can be interchanged to fit the user’s requirements. It complies with the Shelter Center international guidelines.

Target Users (Target Impact Group)

Distributors / Implementing Organizations

Manufacturing/Building Method

circHouse Inc. does not manufacture any parts, but relies on national materials suppliers to provide material and fabrication of each circHouse in a given country. The structure is erected on-site using the materials, a drill, grinder, and tin strips.

Intellectural Property Type

Open Source

User Provision Model

Village Environment will use third party organizations working in disaster-affected areas to distribute the shelters. circHouses will be sold to distributors, and the distributors will determine how the end users will finance the home.Interview with representative

The circHouse packs on a 3 m x 1.2 m pallet with a height of 75 cm, weighing about 600 kg. Without pallets, an 8 m shipping container can accommodate approximately 10 units.

Distributions to Date Status

Several circHouses have been constructed in the USA, but none have been used in the context of a refugee camp or post-disaster situation. The product is still undergoing testing and preparation for distribution for humanitarian application. Interview with representative

Speed of assembly (h)

Less than 24 hours

Footprint area (m²)

Internal volume (m³)

Material composition

Roof panels are 24 gauge, exterior wall panels available in ABS plastic or 24 gauge steel roof panels, window panels are polycarbonate, interior wood panels are luan or veneer plywood, 1 1/2” insulating foil backed foam roof panel, powder coated or spray painted steel components, and conventional galvanized fasteners (nuts, bolts, washers and connecting screws), and polycarbonate sliding windows.

Lifespan (years)

15-30 years

Flammable flash point temperature (ºC)

Unknown

Maximum snow load (kg/m²)

Unknown

Maximum wind speed (km/h)

48.6 km/hInterview with designer

Suitable climates

All climates

Design Specifications

The design of circHouse include the following features:

- 6 m footprint diameter

- 26.5 m2 interior area and 2.2 m wall height with lockable pre-hung door

- Vented

- Materials: Steel, plastic

- Can be wired for any electrical system

- Weight: ~600 kg based on configuration and material selection

Technical Support

Village Environment will repair or replace a material or workmanship defect as a result of installation for a period of ten years from the date of purchase (at their discretion). Interview with representative

Since most materials are sourced locally, any minor issues that occur can most likely be fixed by the homeowner or a trained general contractor.

Replacement Components

According to Village Environment, parts are easily repaired and/or substituted using local materials.

Lifecycle

Expected lifespan of 15 to 30 years depending on materials selected for construction, weather, and climate variations.

Village Environment, Inc. will repair or replace an material or workmanship defect as a result of installation for a period of ten years from the date of purchase (at their discretion). Within the first year, any necessary repair and/or replacements (at their discretion) will be completed at no expense to the customer. Any replacement parts will be provided at no cost, but the customer will be responsible for shipping and handling costs.Interview with representative

Manufacturer Specified Performance Parameters

Performance targets listed by the manufacturer:

- Can be constructed in half a day by 3-4 people

- Versatile, Compact, Durable.

- Engineered to withstand extreme conditions: high wind, heavy rainfall, fire, humans.

- Easily installed on fields, parking lots or firm level surfaces.

- Environmental and needs based flexibility.

- Local material adaptability.

- Units can be connected to build a pod for schools, clinics, or village environments Secure, Lockable doors.

- Can be disassembled and ready to re-locate in 2 hours with zero environmental impact

- Withstands up to 175 km/h (108 mph) winds

- R values range from R-10 to R-20

Vetted Performance Status

The design has been tested for structural integrity and building code compliance in Colorado. circHouses built several years ago are assessed in the field. One of the first circHouses was constructed in Colorado ten years ago, experiences extreme weather, and is still functioning well.Interview with designer

Safety

The circHouse's main goal is to protect the users from harsh outdoor conditions. The circHouse can be designed to provide adequate ventilation in hot climates and sufficient insulation in colder climates, based on the materials used during construction. The structure is designed to protect from high wind speeds (up to 48.6 m/s).

Complementary Technical Systems

Additional options:

- Skylights and Windows

- Solar panels

- Insulation and/or ceiling fan/s

- Multiple beds

- Room dividers

- Unit connections

- High impact ballistic resistance

Academic Research and References

None

Compliance with regulations

Since there are no existing building codes for transitional, post disaster or displaced persons shelter, the circHouse is designed to conform to most standard US building codes.

LGSEA standard light gauge steel framing components, EPDM floor passes ASTM water penetration testing as a roof membrane and provides a seal to the wall sections, ABS wall panel materials all exceed ASTM flame test criteria. The circHouse is fabricated from LGSEA standard light gauge steel framing components routinely used in United States commercial and residential construction. The steel frame is ASTM rated and Powder coated, and the ribs are composed of ABS plastic and fire rate, though the fire rating information has not been disclosed. Interview with representative

Other Information

The circHouse was initially designed for vacation/luxury outdoor housing, and has since pivoted their business structure to meet the needs of disaster refugees around the globe through Village Environment. The Village Environment website is currently down while they work on obtaining funding and partners for implementation of circHouse for humanitarian purposes.Interview with designer

Get more information about Solutions Library and its features.

Learn MoreHave thoughts on how we can improve?

Give Us Feedback