A Breath of Fresh Air 2.0: Optimizing Sustainable Protein Production from Waste

Fresh Life is a circular economy company that focuses on the conversion of organic waste (such as sewer waste and plant waste) into organic fertilizer, briquettes, and insect-based animal feeds. The project goal was to improve the airflow control (temperature and humidity) of the black soldier fly (BSF) larvae production greenhouse by evaluating and optimizing the current design.

Conversion of the organic waste into useful end products is achieved through the use of BSF larvae. In order to ensure that the yield of the BSF larvae is maximized, the rearing of the larvae is done in greenhouses, where conditions such as temperature and relative humidity can be controlled. Airflow and circulation inside the greenhouse (macro climate) and in the bed region (microclimate) have a significant effect on BSF yield. Adequate fresh air has to be supplied into the greenhouse and bed region to ensure that there is no build up of Ammonia and CO2 and also to make sure that temperatures are maintained within an acceptable operational range.

Design concepts were modeled in Autodesk Fusion 360, and Autodesk CFD was used to evaluate the air circulation. The computational domain used in the CFD analysis was modeled to mirror real-world operating conditions in the greenhouses. A weighted selection matrix was then utilized to select the final design concept based on factors such as CAPEX, OPEX, ease of fabrication and installation, and performance. The final design concept selected provides a significant improvement in airflow and circulation in the bed region; promoting aeration, as well as better temperature and humidity control. These improvements in the microclimate would provide conducive conditions for larvae growth, thus resulting in increased yield (in relation to larvae body mass) by the end of the growth cycle.

The final design concept, which was selected based on the CAD and CFD work carried out in this phase of the project, will be fabricated, and experimental pre-feasibility trials conducted in a specially designed respiration chamber at Fresh Life. In addition to this, the selected design concept will provide the basis for further CFD modeling for the full-scale greenhouse.

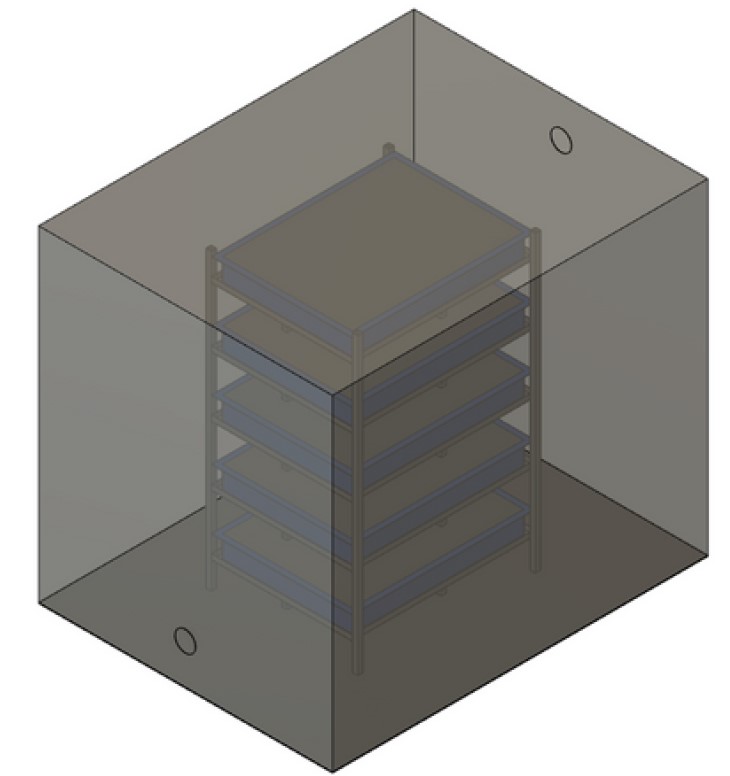

Respiration chamber and larvae bed arrangement in greenhouse, Attribution: Isaac Charles Kimani Njoroge and Fresh Life