Farm-based food processing via dehydration is a significant way to save post-harvest losses and help farmers earn extra income by reducing the waste and selling value-added products. A combo cutter is a machine that is used for preprocessing before it is dehydrated. This automatic machine cuts large quantities of vegetables and fruits into defined size cubes so that they can be efficiently dehydrated in solar dehydration machines. Commodities such as ginger, garlic, onion, and turmeric are comparatively easy to slice, whereas tomatoes are more challenging since they are soft and squeezable. In collaboration with Science for Society (S4S) Technologies, the goal of this project was to solve the issue of mass tomato cutting by designing an automatic machine that can efficiently dice tomatoes into 14×14 mm size cubes.

To address this problem, prior art was identified via academic and market research. Through this search of the literature, parameters such as blade angle, applied shear cutting force, and non-skid fixture were identified as playing a critical role in the efficient cutting of tomatoes. Additionally, through market research we discovered that automatic machines have been designed for industry and for assembly line infrastructure, but the cost of the machines was 10 to 100 times higher than what we were trying to build for rural India. On the other hand, manual machines available in the market were cheaper and performed efficiently but had limitations for bulk processing.

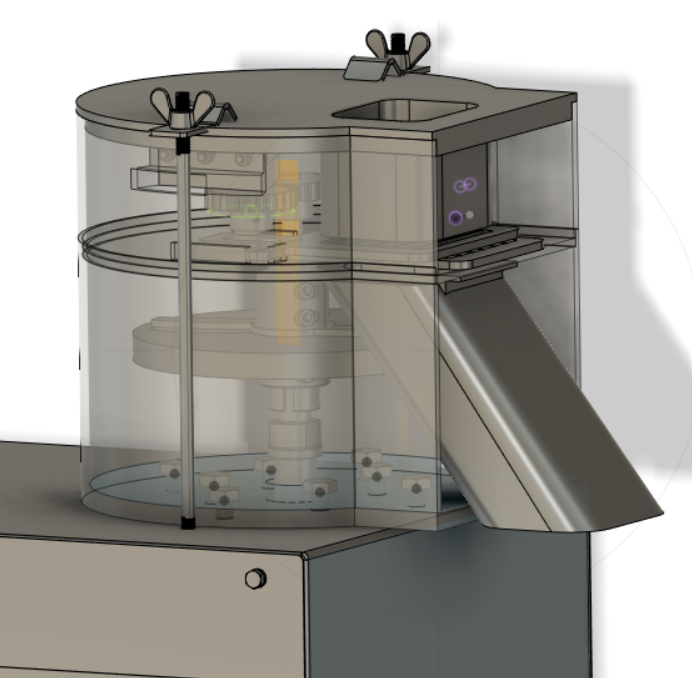

Combining findings from the academic and market research, the team collaborated using Slack, Asana, and Autodesk Fusion 360 to design a machine that met the requirements. These tools helped to create the 3D assembly files of the machine, manufacturing 3D CAD Models, CAD drawings, detailed Bill Of Material (BOM), and assembly instructions making work easier for creating the first prototype.

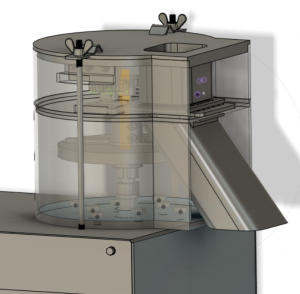

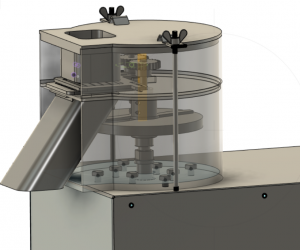

Figure: 3D CAD Model of Automatic Tomato Cutting Machine

ADVISORS AND COLLABORATORS: Ashwin Pawade, Co-Founder and Lead (HardTech and Partnerships), S4S Technologies, India; Mandar Palande, Manager (Hard Tech), S4S Technologies, India

E4C 2021 PROGRAM MANAGEMENT TEAM: Mariela Machado, Senior Program Manager; Grace Burleson, Research Manager; Marilynn Holguín Clover, Program Coordinator; Jonathan Kemp, Program Associate