Agriculture

December 17, 2024

Flexi Biogas BG5

Read SolutionImplemented by

Biogas International Limited

Updated on January 22, 2024

·Created on June 22, 2016

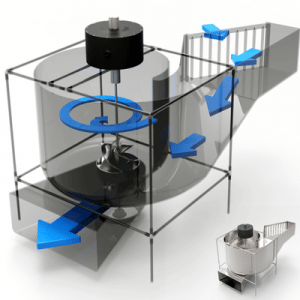

Sistema Biobolsa is a pre-fabricated biodigester that converts daily farm waste waste into renewable energy and organic fertilizer.

Sistema Biobolsa is a continuous flow, tubular, prefabricated, modular, flexible biodigester. The system is composed of pre-fabricated components in order to optimize packaging, transportation and easy installation. It is easy to operate and maintain, and has a long durability.

Target SDGs

SDG 7: Affordable and Clean Energy

SDG 8: Decent Work and Economic Growth

Market Suggested Retail Price

$7,568.00

Target Users (Target Impact Group)

Household, Community, Small and Medium-sized Enterprises

Distributors / Implementing Organizations

The product is distributed by Sistema Biobolsa itself and a network of distributors in all the targeted regions in Mexico and Nicaragua.

Competitive Landscape

Direct competitors include Nopalimex.

Countries

Cuba, Haiti, Honduras, India, Mexico, Nicaragua, Peru

Manufacturing/Building Method

The Biobolsa is manufactured in Mexico by a standard series production line.

Intellectural Property Type

Select Type

User Provision Model

Interested buyers must contact the manufacturer. Biobolsa requires the following information to confirm the viability of the project:

Users can also obtain the product from local distributors like Tecnosol in Nicaragua.

Distributions to Date Status

4,756 as of 2018.

Output energy product

Unknown

Average daily biogas production (m3/day)

9.7 for a 40 m3 size

Description of waste source(s)

Livestock (cow, pig, sheep, goat, horse), human waste, slaughterhouse waste

Waste input requirements (kg per hour or day)

242 L/day (equivalent to 24 semi-confined cows) for a 40 m3 size

Description of other input requirements

Unknown

Other input requirements (amount per hour)

Unknown

System dimensions (m)

Unknown

Design Specifications

The Biobolsa has two main components, a reactor and the tubes and assemblies, The reactor is made with linear low density polyethylene (LLDPE) geomembrane of 1 to 1.5 mm thickness and the tubes and assemblies are made of hydraulic and sanitary PVC. The Biobolsa has 11 base sizes of reactors, with capacity to operate from 4 m3 to 40 m3 of liquid phase. The dimensions for each base size can be found in the company's catalog.

Technical Support

There is a free technical support provided by Sistema Biobolsa's technicians:

A Customer's Installation manual available.

Replacement Components

Sistema Biobolsa provides a replacement service.

Lifecycle

The Biobolsa lasts over 15 years. The geo-membrane, tested in lab under UV radiations, has an estimated lifetime of 50 years.Interview with manufacturer in 2018.There is 1 year warranty on any manufacturing defect. Manufacturers also provide 20 year warranty on the geo-membrane.

Manufacturer Specified Performance Parameters

Performance targets are established depending on the climate and the type of animal manure used. Manufacturers specify the following target gas production: 14.6 m3, 9.7 m3, 5.8 m3 for the 40 m3 size for the following climate conditions: hot climate (>23°C), temperate climate (15°C to 22°C) cold climate (<15°C) respectively. The manufacturers have a Sizing Table available so that end users can look for their best size option and production.

Vetted Performance Status

None.

Safety

Since extreme caution is necessary when working with biogas, farmers are strongly encouraged to put a wiring around the system to restrict access. They also have to follow a formation taught by Sistema Biobolsa. Adequate ventilation, appropriate precautions, good work practices, and adequate personal protective equipment will minimize the dangers associated with biogas.

Complementary Technical Systems

The company also offers other products that can be adapted to use the biogas produced by the Biobolsa like burners, stoves, water heaters and biogas motors.

Academic Research and References

Garwood, A., Network for biodigesters in latin america and the caribbean: case studies and future recommendations. Inter-American Development Bank; 2010 Dec [cited 2015 Jul 20].

Holm-Nielsen, J.B., Al Seadi, T., Oleskowicz-Popiel, P., The future of anaerobic digestion and biogas utilization. Bioresource technology. November 2009;100(22):5478-5484.

Smith R., Eaton A., Arshad H., Ricketts P., Global crowd funding to increase accessibility for small-scale biodigester projects. Boiling point. 2014;62:2-5.

Sistema Biobolsa. 2020. Sistema.bio Product Catalog. Sistema.bio.

Sistema Biobolsa. 2021. User Manual. Sistema.bio.

Sistema.bio – Certified B Corporation – B Lab Global. n.d. www.bcorporation.net.

Compliance with regulations

Sistema Biobolsa is certified by B-Corporations. It also has the IS0 9001 certification.Interview with manufacturer

Evaluation methods

Sistema Biobolsa developed their own criteria. They rely on traceability of each component from the manufacturing plant to field installation. Interview with manufacturer

Other Information

The design allows the interconnection of Biobolsa, aiming at increasing the system’s treatment capacity volume from 50m3 to 240 m3 in liquid phase.

Sistema Biobolsa has won many awards and recognitions: Social Business of the year, 2010 Businesses in Development (BiD Network); Ashden Award Finalists 2010; Green Tech Challenge Finalists; 2nd place Iniciativa México 2011; International Development Exchange Grant; Switzer Environmental Leadership Fellow; Echoing Green Finalists 2012; Fellow Ashoka, New Ventures México Negocio; Top 10 Entrepreneur of Latin America in 2012 by Univision; Buckminster Fuller Challenge 2014 Finalists.

Expert advisors have indicated that polyethylene, the main material, is cheap but has a shorter lifetime than other quality materials such as PVC (only the fittings are of PVC).

Agriculture

December 17, 2024

Implemented by

Biogas International Limited

Agriculture

June 23, 2024

Implemented by

Musana Carts

Agriculture

December 17, 2024

Agriculture

December 17, 2024

Implemented by

Sun King

Agriculture

December 2, 2024

Implemented by

Turbulent

Agriculture

December 2, 2024

Implemented by

Energy Systems & Design

Agriculture

December 17, 2024

Implemented by

ATEC Biodigesters International

Agriculture

January 28, 2024

Implemented by

Burro

Agriculture

January 25, 2024

Implemented by

d.light

Agriculture

January 27, 2024

Implemented by

M-KOPA

Have thoughts on how we can improve?

Give Us Feedback