Agriculture

January 11, 2024

Updated on August 15, 2024

·Created on June 21, 2017

The Struvite Reactor Tank converts urine into fertilizer.

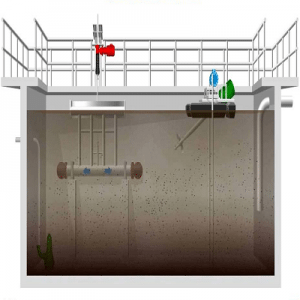

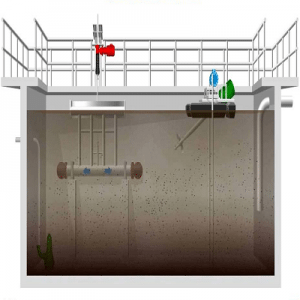

The Eawag low-cost struvite reactor tank is a tool to produce struvite powder from urine. Struvite contains nutrients such as phosphorus necessary for plant growth. The product aims to improve crop production in low-income communities and improve resource reuse. Phosphorus is becoming scarce and as a result, it is becoming increasingly important to find new phosphorus sources. Urine is available wherever there are humans and by constructing a struvite reactor tank and selling/using struvite on farmland, individuals can improve their economic situation while also simplifying waste management since it is easier to handle and make use of urine and faeces separately than when mixed.

Tanks to produce struvite from urine can be advanced. The pictured low-cost versions are targeted towards the global south with implementation so far in Nepal and South Africa.

This is an open-source technology, and both the Construction Manual and device schematics, which illustrate the basic steps of struvite production in the precipitation reactor, are publicly available. The manual can be found here, and the schematics are available here.

Direct and indirect competitors include fertilizers sold in stores, or applying urine directly or after mixing with water.

Target SDGs

SDG 6: Clean Water and Sanitation

Market Suggested Retail Price

$367.00

Target Users (Target Impact Group)

Household, Community

Distributors / Implementing Organizations

Eawag has implemented various projects in both Nepal (STUN) and South Africa (VUNA).

Countries

Nepal, South Africa

Manufacturing/Building Method

The Construction Manual provides guidance to interested individuals and households to build a tank using plastic containers or galvanized steel sheets.

The Operation Manual for a larger system includes further instructions for operation and maintenance based on experiences from earlier implementations.

Intellectural Property Type

Open-source

User Provision Model

This product is not for sale. Open source information packs available online (e.g. Construction Manual and Operation Manual).

Distributions to Date Status

Unknown

Flow rate (L/min)

Unknown

Power Supply Type

No power required

Technology type

Magnesium treatment

BOD Removal Efficiency

Unknown

COD removal efficiency

Unknown

NH4-N Removal Efficiency

30-60%

TSS removal efficiency

Unknown

Total Phosphorus Removal Efficiency

90%

Fecal Coliform Removal Efficiency

Unknown

Design Specifications

The tank is made of metal such as galvanized sheet metal or stainless steel. The stirring mechanism is also made of metal. The nylon filter bag allows liquid to pass through but keeps the struvite inside the bag. There is also a plastic switch between the tank and bag so that flow can be regulated. The dimensions of the tank can be adjusted according to the users' preferences.

Source-separated urine and magnesium is added to the tank and mixed manually for 10 min with a crank connected to stirring blades in the tank. A valve connecting the tank to a nylon filtering bag is then opened. The mixture enters the filtering bag so that struvite stays in the bag while liquid runs through. The bag is then removed from the tank and dried for 1-2 days. The struvite in the bag can then be applied as fertilizer.

Technical Support

As an open-source technology, users can refer to online manuals to carry out maintenance works.

Replacement Components

The product is generally repairable using available materials. The components and exact materials of the product can vary while still maintaining the same function. Online manuals are available for reference.

Lifecycle

The lifecycle of the tank is long but some components may need to be replaced continuously such as the nylon bag. The product is mainly constructed by recyclable materials such as metal and plastic. The nylon bag is the most challenging to recycle correctly, especially in the global south.

Manufacturer Specified Performance Parameters

The amount of struvite depends on the size of the tank and the efficiency of the process. When filled and mixed with added magnesium, results should be achieved after 10 min of stirring following by air drying for 1-2 days.

The goal of the product is to increase crop production sustainably and while potentially creating another source of income for people selling the struvite. The tank is stated by Eawag as low-cost and easy-to-use. Furthemore, the ease of transportability of struvite and application of struvite powder than urine directly, are also desireable characteristics.

Vetted Performance Status

Field experiments have shown that the reactor can recover over 90% of the phosphorus in the urine.

Safety

The tank is driven manually, so there are no hazards regarding electricity. However, there are potential health risks regarding unsafe contact with the urine when filling the tank.

Complementary Technical Systems

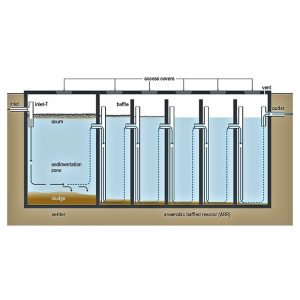

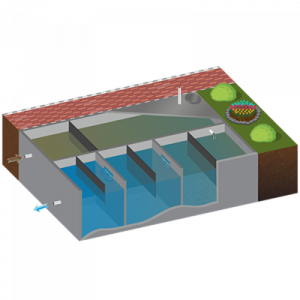

Users and organisations can automate stirring and add a rotating biological contractor (RBC) to reduce nitrogen content in the effluent. Schematics to inform this option is found in the Operation Manual.

Academic Research and References

Etter, B., Tilley, E., Khadaka, R., Udert, K., 2011, Low-cost struvite production using source-separated urine in Nepal, Water Research, 45: 852-862

Tilley, E., Gantenbein, B., Khadka, R., Zurbrügg, C., Udert, K., 2009, Social and economic feasibility of struvite recovery from urine at the community level in Nepal, Presented at the International Conference on Nutrient Recovery from Wastewater Streams, Vancouver, Canada, 10-13

Compliance with regulations

Application of urine as fertilizer is legal but if the struvite product is going to be patented and sold on the market as fertilizer, permission may be required. An example of this is Aurin fertilisers.

Evaluation methods

The reactor has been developed and tested in regards to percentage of nutrient recovery, production cost and demands of operation. There is also an academic article written about the social and economical feasibility using the product in communities in Nepal.

Other Information

Agriculture

January 11, 2024

Agriculture

August 15, 2024

Implemented by

AnoxKaldnes

Agriculture

January 12, 2024

Agriculture

August 16, 2024

Agriculture

January 12, 2024

Implemented by

Emergy Enviro Pvt. Ltd

Agriculture

February 4, 2024

Implemented by

Tank Connection

Agriculture

August 8, 2024

Implemented by

Patrick Kiruki, Banza Sanitation

Agriculture

January 10, 2024

Implemented by

Dr. David Manz, University of Calgary

Agriculture

August 13, 2024

Implemented by

The Africa Trust

Agriculture

August 14, 2024

Implemented by

Envirosan

Have thoughts on how we can improve?

Give Us Feedback