Agriculture

August 15, 2024

Struvite Reactor Tank

Read SolutionImplemented by

EAWAG

Updated on January 11, 2024

·Created on October 1, 2018

Sequential Batch Reactors (SBR) are aerobic wastewater treatment systems using activated sludge processes.

Sequential Batch Reactors (SBR) are wastewater treatment systems which employ suspended-growth processes. These processes are achieved through injecting oxygen to both maintain aerobic conditions and mix the wastewater, which activates sludge. Activated sludge systems remove organic matter, nutrients, biochemical oxygen demand, and chemical oxygen demand. However pathogen removal is low. The treated water can either be inject back into the groundwater table, or used for some agricultural purposes.

Target SDGs

SDG 6: Clean Water and Sanitation

Target Users (Target Impact Group)

Community, Small and Medium-sized Enterprises, Public Sector Agencies

Distributors / Implementing Organizations

Evoqua Water Technologies; Aqua-Aerobic Systems, Inc.; Bluevita GmbH & Co. KG; Enta Treatment Systems

Competitive Landscape

Direct competitors include AnoxKaldnes Moving Bed Biofilm Reactor and Membrane Biofilm Reactor.

Regions

Europe, North America

Countries

India

Manufacturing/Building Method

Unknown

Intellectural Property Type

Open-source

User Provision Model

Direct sales from local manufacturers.

Distributions to Date Status

Over 1300 plants have operated.

Flow rate (L/min)

16000 L/min

Power Supply Type

Electrical

Technology type

aerobic treatment, activated sludge

BOD Removal Efficiency

95%

COD removal efficiency

90%

NH4-N Removal Efficiency

90%

TSS removal efficiency

95%

Total Phosphorus Removal Efficiency

90%

Fecal Coliform Removal Efficiency

96%

Design Specifications

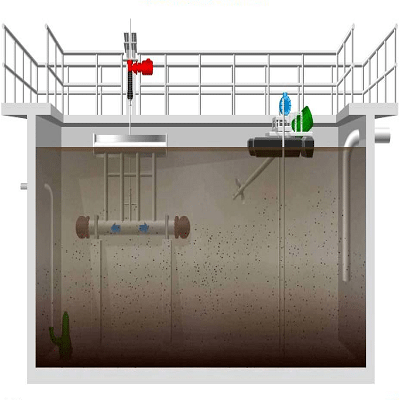

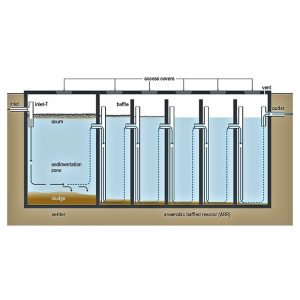

The SBR tank is designed to add oxygen to wastewater, which enables bacteria to oxidize the organic matter. Once aeration stops, sludge settles in the tank. After settling the sludge and water is separated, and the effluent continues to flow through the system. In most situations, plants are designed with at least two connected SBR to allow for continual wastewater processing.

A diagram for the SBR illustrates the processes involved in wastewater treatment.

The SBR operates in two stages in the schematic: during aeration and during settling.

Technical Support

The SBR systems require continuous control by operators. Manufacturers provide technical support and operation training for operators.

Replacement Components

Replacement components can be purchased directly from manufacturers.

Lifecycle

Unknown

Manufacturer Specified Performance Parameters

SBR were developed to require minimal land, produce effluent of high quality, operate completely automated, and be resistant against shock-loads.

Vetted Performance Status

Unknown

Safety

Precautions must be taken during operation to ensure that operators do not come into unsanitary contact with the wastewater or sludge.

Complementary Technical Systems

This treatment system must be coupled with water distribution systems to transport the influent and effluent wastewater to and from the reactor. In addition depending on the desired application of the treated wastewater, further treatment might be required.

Academic Research and References

Strous, M., Heijnen, J., Kuenen, J. & Jetten, M,1998, The sequencing batch reactor as a powerful tool for the study of slowly growing anaerobic ammonium-oxidizing microorganisms. Applied Microbiology and Biotechnology 50: 589-596

Wang, L., Li, Y., 2009, Sequencing Batch Reactors. Biological Treatment Processes 8: 459-511

Morgenroth, E. et. al., 1997, Aerobic granular sludge in a sequencing batch reactor. Water Research 31 (12): 3191-3194

Zeng, R., Lemaire, R., Yuan, Z. & Keller, J., 2003, Simultaneous nitrification, denitrification, and phosphorus removal in a lab-scale sequencing batch reactor. Biotechnology and Bioengineering 84(2): 170-178

New England Interstate Water Pollution Control Comission, 2005, Sequencing Batch Reactor Design and Operational Considerations.

Ganjidoust, H., Ayati B., 2004, Use of Sequencing Batch Reactors (SBRS) in treatment of wood fiber wastewater, Environmental Science

Wang, D-B. et al., 2008, Biological phosphorus removal in sequencing batch reactor with single-stage oxic process, Bioresoruce Technology 99(13): 5466-5473

NG, J.W. et al., 1993, Fate of coliforms and coliphages in the sequencing batch reactor (SBR), Bioresource Technology 46(3): 197-205

Goal 6. Available: https://sdgs.un.org/goals/goal6

Compliance with regulations

Unknown

Evaluation methods

The systems are evaluated visually to ensure that each tank proceeds through the five treatment stages: fill, react, settle, decant, and idle.

Other Information

Factsheet - Sequence Batch Reactor (SBR)

Agriculture

August 15, 2024

Implemented by

EAWAG

Agriculture

August 15, 2024

Implemented by

AnoxKaldnes

Agriculture

January 12, 2024

Agriculture

August 16, 2024

Agriculture

June 23, 2024

Implemented by

LoooP Creative Ltd

Agriculture

January 10, 2024

Implemented by

NRSRelief

Agriculture

January 22, 2024

Implemented by

Sanivation

Agriculture

December 13, 2023

Implemented by

change: Water

Agriculture

December 27, 2023

Implemented by

Nippon Basic Co. Ltd.

Agriculture

January 8, 2024

Implemented by

Gadgil Lab, University of California Berkeley

Have thoughts on how we can improve?

Give Us Feedback