Agriculture

June 23, 2024

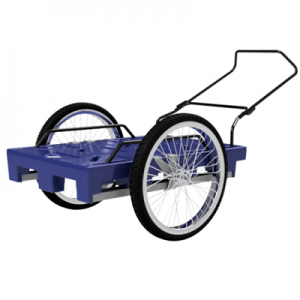

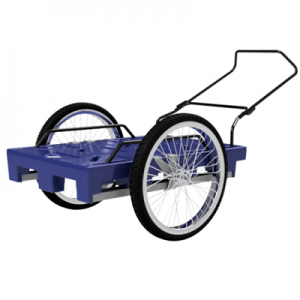

AguaPallet

Read SolutionImplemented by

LoooP Creative Ltd

Updated on January 8, 2024

·Created on September 11, 2019

The Vacutug is a portable machine used to extract fecal sludge from septic tanks and pit latrines and transport them to a sewage disposal site.

The Vacutug is a portable machine used to extract fecal sludge from septic tanks and pit latrines and transport them to a sewage disposal site. The Vacutug was originally designed by UN-HABITAT, evolving out of the need for emptying pit latrines in highly-dense informal settlements and peri-urban areas. The Vacutug serves to both empty and transport fecal sludge, is highly maneuverable, and can access hard-to-reach extraction points often inaccessible to larger emptying machines.

Target SDGs

SDG 6: Clean Water and Sanitation

Market Suggested Retail Price

$5,100.00

Target Users (Target Impact Group)

Household, Community

Distributors / Implementing Organizations

The Vacutug is manufactured by MAWTS in Bangladesh and has been implemented by organizations including EEPCO, MSF, WaterAid, ENDA, Mvula Trust, Sulabh International, and Shubashati.

Competitive Landscape

Direct competitors include The Gulper.

Regions

Worldwide

Manufacturing/Building Method

Manufactured by MAWTS in Bangladesh

Intellectural Property Type

Patent

User Provision Model

This project is distributed by humanitarian organizations, and has been implemented in Kenya, Tanzania, Mozambique, Senegal, Ghana, South Africa, India, and Bangladesh.

Distributions to Date Status

Exact number of Vacutugs distributed is unknown, but at least 10 have been piloted in field trials.

Emptying speed (L/min)

4300 L/min

Accessories needed

Shovel to open cover, full PPE clothing for operators, water depending on sludge thickness, petrol for vehicle

Transport mechanism

Models range from a self-driving 4-wheeler to a trailer attachment to a truck.

Transport speed (km/hr)

Mark II model is 5 km/hr, ranging to 100 km/hr of the Mark VII.

Storage volume of transportation (L)

Ranges from 500 L to 2000 L and larger, depending on the model.

Design Specifications

The Vacutug generally needs one driver and one or two emptiers for operation. The machine uses a diesel engine-powered vacuum pump to extract sludge from a hose into a collection tank. After extraction, the sludge is transported to a disposal site where it can be discharged by gravity feed or pump pressure out of the hose.

The following are design specifications of different models:

MK-II

-Driving details: Self-driving 4-wheeler, engine powers both the pump and drivetrain, vertically mounted sludge collection tank. Suitable for use on narrow streets and hard to reach extraction sites, on flat ground, and on sites within a short distance.

-Tank Capacity: 700 L

-Pump: MEC 2000/P

-Engine: 10.5 hp diesel

-Max speed: 5 km/h

MK-III

-Driving details: 2-wheeler trailer unit that must be towed by a tractor or large pick-up truck, horizontally mounted sludge collection tank, this is suitable for use on wider streets and highways.

-Tank Capacity: 2000 L

-Pump: MEC 2000/P

-Engine: 12 hp diesel

-Max speed: 45 km/h

MK-IV and V

-Driving details: The MK-IV and V are identical other than the size of the tank. It is a 3-wheeler BRV (Bangladesh Rural Vehicle), and the engine powers both the pump and drivetrain. There is a horizontally mounted sludge collection tank, and this is suitable for use on narrow streets and highways.

-Tank Capacity: 700 L (MK-IV) and 1000 L (MK-V)

-Pump: MEC 2000/P

-Engine: 12 hp diesel

-Max speed: 30 km/h

MK-VI

-Driving details: This is a 4-wheeler mini truck with a horizontally mounted sludge collection tank and a top cover concealing the engine and pump. Suitable for use on narrow streets, highways and for longer distances.

-Tank Capacity: 1000 L

-Pump: MEC 2000/P

-Engine: 12 hp diesel

-Max speed: 70 km/h

MK-VII

-Driving details: This is a 4-wheeler large truck with a horizontally mounted sludge collection tank, suitable for use on wide streets, highways and for longer distances.

-Tank Capacity: 2000 L

-Pump: MEC 2000/P

-Engine: 12 hp diesel

-Max speed: 100 km/h

Technical Support

Provided by local technicians

Replacement Components

Replacement parts may be available locally or can be ordered through MAWTS, and include o-rings, hose clips, 1.5-in ball valve, 3-in ball valve, 3-in x 15 m flexible hose, air hoses, and a pump rebuild kit.

Lifecycle

Unknown

Manufacturer Specified Performance Parameters

Initial design criteria specified the Vacutug would be maneuverability in high-density settlements, that capital cost should be affordable to small-scale entrepreneurs, that it should be designed for local manufacture, that operating costs should be covered by generated revenues, that the Vacutug is capable of transporting the waste to the disposal point, the system can effectively evacuate compacted sludge from latrines, and easy operation and maintenance.

Vetted Performance Status

In the first pilot, the Kenya Water and Health Organization used the Mark I Vacutug model on a commercial basis and during the two year period earned a total profit of 36% on its overheads and estimated that over 400,000 people benefited directly from the use of the Vacutug. Ultimately it developed mechanical problems that took ten months to repair. During the second pilot of 9 Mark II Model Vacutugs produced by MAWTS, a number of shipping issues arose to get the Vacutugs to the pilot countries. Successes included coverage of operating costs by generated revenues and a cheaper cost than a larger tanker, but it is still expensive. Other challenges include obtaining spare parts, handling compacted sludge, maneuverability when needed to reverse or go up slopes, and the slow speed on roads.

Safety

The operator should not come into contact with the fecal sludge and must dispose of it according to regulations. Personal protective equipment should include at least a protective suit, face mask, waterproof boots, gloves, and safety googles for the operator. Avoid sparks, such as lighting a cigarette, near the Vacutug. Follow all Operation Procedures while using the machine.

Complementary Technical Systems

Petrol for fuel, and the tank must be flushed with water once per day and cleaned every 100 discharges to prevent sludge build up. An experienced technician should be call to service the air, fuel, and mobile filters as needed or replace the hose.

Academic Research and References

Opel, A. and Bashar, M.K., 2013, Inefficient technology or misperceived demand: the failure of Vacutug-based pit-emptying services in Bangladesh. Waterlines, 32(3), pp. 213-220.

Jakariya, M., et al., 2018, Modeling on environmental-economic effectiveness of Vacutug technology of fecal sludge management at Dhaka city in Bangladesh. Modeling Earth Systems and Environment, 4(1), pp. 49-60.

Parkinson, J. and Quader, M., 2008, The challenge of servicing on-site sanitation in dense urban areas: Experiences from a pilot project in Dhaka. Waterlines, 27(2), pp. 149-163.

Spit, J., et al., 2015, Desludging of difficult sludge with easy equipment designs: results of field-testing in Blantyre, Malawi. Proceedings of the 38th WEDC International Conference.

Thye, Y.P., et al., 2009, Pit latrine emptying: technologies, challenges and solutions. Proceedings of Engineering Without Borders UK National Conference.

O’Riordan, M., 2003, Investigation into Methods of Pit Latrine Emptying. University of Kwazulu-Natal.

Compliance with regulations

Unknown

Evaluation methods

Evaluated for emptying efficacy, speed, maintenance needs, and maneuverability.

Other Information

None

Agriculture

June 23, 2024

Implemented by

LoooP Creative Ltd

Agriculture

January 10, 2024

Implemented by

NRSRelief

Agriculture

January 22, 2024

Implemented by

Sanivation

Agriculture

December 13, 2023

Implemented by

change: Water

Agriculture

December 27, 2023

Implemented by

Nippon Basic Co. Ltd.

Agriculture

January 8, 2024

Implemented by

Gadgil Lab, University of California Berkeley

Agriculture

September 19, 2023

Implemented by

Grundfos

Agriculture

January 11, 2024

Implemented by

Precious Plastic

Agriculture

January 10, 2024

Implemented by

Southern Highlands Participatory Organisation (SHIPO)

Agriculture

January 25, 2024

Implemented by

DEKA Research & Development

Have thoughts on how we can improve?

Give Us Feedback