The bamboo fronds above a Vietnamese farming community sparked the idea for a business and a brand of oral care products we call Juni Essentials. Since inception, we have had two broad goals: to employ engineering and design principles to build an environmentally sustainable product, and to deliver profits to financially struggling subsistence farmers. We have gone a long way toward meeting the goal of environmental sustainability, while, of course, we are investigating ways to improve. The second goal has been harder to reach, but research is underway.

2020 was a big year for us professionally at Juni Essentials. Building on the success of our toothbrushes in the Korean market (under the brand Dr. Noah), we started selling in the United States as the Juni Essentials brand, with a product line focused around the juni bamboo toothbrush, and a starter kit that (in addition to two juni brushes) includes an all-natural toothpaste plus a metal toothpaste wringer, diatomite toothbrush holder, and a bamboo travel case. For both the Dr. Noah and Juni brands, a key component of our company’s values is sustainability and our commitment to the environment, which has caused us to face certain challenges and learn some valuable lessons along the way.

See Five Questions with Kathy Ku: Co-founder of SPOUTS of Water

Before we dive in with the lessons we have learned from our experience, it will be useful to know what we generally mean by sustainability, and how that relates to our products:

Broadly, we use “sustainability” to mean using methods that cause no harm to the environment. Of course, there’s many ways in which this can be put into practice, but this helped to guide two key principles in terms of our production process:

- Use materials that are biodegradable and won’t clog a landfill

- Develop and employ sustainable production processes

Principle 1: Materials

What inspired Dr. Noah (and now Juni) to first begin making sustainable oral care products was the advantages of bamboo. Dr. Noah’s founder Fran had been a dentist for many decades when he came traveled to Southeast Asia and saw the abundance of bamboo. He noticed that this giant of the grass of plants family thrived in communities of subsistence farmers, people who would greatly benefit from the demand for bamboo that could be sold in the global market. Bamboo also has the advantages of strength, enabling a variety of materials to be made from it.

What was important to our pursuit of sustainability, however, was that bamboo has environmental advantages over other materials. Of course, it’s biodegradable (unlike plastic), but according to Project Drawdown, it also “sequesters carbon out of the air faster than almost any other plant, and can thrive on inhospitable degraded lands—the ideal place to put bamboo to work.” (Hawken, Paul. Drawdown: The Most Comprehensive Plan Ever Proposed to Reverse Global Warming, 2017). It also grows extremely fast (up to 1 meter per day), which makes it easy to produce any amount needed to fit demand. Bamboo is often grown in mountainous areas that have temperate climates where lots of subsistence farmers are based, so further developing the bamboo industry can create a sustainable, profitable industry for the people who live in those areas.

See Solutions to Reverse Global Warming, a webinar by Joe Speicher at Autodesk Foundation and Chad Frischmann at Project Drawdown

All of these benefits made bamboo an obvious choice to be used in our flagship toothbrush, as well as the toothbrush case, and we will be looking for additional opportunities to use bamboo in our products.

While prioritizing as little use of plastic as possible (our products are almost entirely plastic-free, with few exceptions), sourcing other sustainable materials is an ongoing challenge, primarily in our toothpaste.

Principle 2: Production Processes

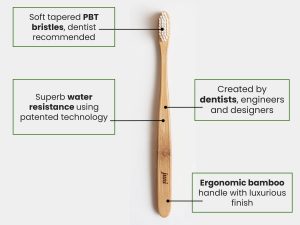

The production process for the juni brushes contains a few key steps. First, we receive bamboo sticks from our suppliers that we then cut into the shape of toothbrushes. Then, in order to make the surface smooth and water resistant, we use a patented production process that utilizes heat treatment to induce carbonization of the bamboo that gives it that richer color and sleek finish.

We collect the bamboo shavings left over after shaping each toothbrush and sell them to other manufacturing industries.

Furthermore, we coat the bamboo with a food safe material to increase water resistance. Next, we drill holes where the bristles need to go and later, we do the tufting of the bristles in our in-house factory in Korea.

The raw materials from the suppliers we work with are small shareholder farmers and our bamboos are Forest Stewardship Council certified. In terms of sustainability within our production process, we are still trying to make improvements to ensure that the waste we generate is recycled back. The goal is carbon neutrality. We collect the bamboo shavings left over after shaping each toothbrush and sell them to other manufacturing industries. Our scraps go into pellets and other items, ensuring that materials are not wasted.

In addition, whatever carbon emissions we generate from shipping, we purchase back as carbon credits to help with reforestation projects across the globe.

Ongoing Questions and Challenges

As is the case with the above principles, creating broader positive impact as a company is an ongoing challenge, both in terms of deciding how best we can support our customers, as well as prioritizing what’s best for the planet. A key way we want to ensure we are giving back is to be a part of 1 percent for the Planet. We give 1 percent of all sales back as donations to environmental groups and causes.

In order to continue expanding our impact, we constantly seek and receive feedback from our customers. We do a lot of focus group studies, answering questions such as “What should our next toothbrush offer be?” “Should we make improvements on our current products?” “Do we add new lines of products that complement our existing products?” “Do we introduce interdental toothbrushes, or do we make toothbrushes that have variations in the handle?”

Our patented production process allows for a nice finish on the toothbrushes, but what if there was a way to injection-mold eco-friendly bamboo-based toothbrushes as opposed to this two-dimensional milling process we have right now? Our research and development team is working on answers to these questions in collaboration with partners we have in universities and other industry leaders.

We are making these great products, but we are still far from the original goals we set out to accomplish: to use engineering to develop industry in an area that is often ignored.

Another challenge is the inability to use bamboo from all environments. As discussed, the idea for this company struck when one of our co-founders travelled to Vietnam and saw the abundance of bamboo in an area where most people were subsistence farmers who could benefit from bamboo sales. Unfortunately, there are differences in bamboo quality across regions, and we had difficulty manufacturing these products using the raw materials from Vietnam due to a different strength of the bamboo. We have a patented process where we are making these great products, but we are still far from the original goals we set out to accomplish: to use engineering to develop industry in an area that is often ignored. To this day, we are spending time and resources on research and development to figure out how to best use the bamboo sourced from Vietnam to develop the industry there. In other words, how can we use engineering principles to overcome the natural challenges that arise from the raw materials from Vietnam? The key is to find out what we can do better to overcome the challenges that different bamboo variations present.

About the Authors

Kathy Ku is the co-founder of Juni Essentials, an all-natural, sustainable oral care brand, and before that, SPOUTS of Water, an award-winning social start-up that manufactures water filters in Uganda. Kathy has a bachelor’s and master’s degree in engineering from Harvard University and is currently pursuing her MD/MBA from Stanford University.

Ali AlQeisi has worked in journalism and media reporting in international settings for The Washington Post and AFP. He has also previously served both in the US Embassy and the British Embassy in Baghdad. Ali has his Master’s degree in Media and Public Relations from the University of Leicester.

Rebecca Liebschutz has diverse experiences working in business development and revenue growth in the social enterprise and international development sector. She was previously the Director of Sales and Marketing at SPOUTS of Water, a ceramic water filtration company in Uganda, and is currently the Chief of Staff at Binti, a technology company that strives to help place every child in loving homes.

What a terrific engineering initiative. This is a really helpful and informative article by Ali AlQeisi , Kathy Ku and Rebecca Liebschutz. The world urgently and badly needs solutions like this so that consumers do not have to depend on e.g., plastic toothbrushes. The beaches here, in Chile are often covered in plastic and that includes plastic toothbrushes. Where can you buy these and how do they compare with e.g. the cost of plastic toothbrushes? What is the Green Premium?” that people will have to pay. On a practical level, how long do they last?

What a terrific site this is too! I have registered and will be following your articles and sharing them with advanced English students in Chile. Have a great day and keep up the great work! Trevor