Agriculture

June 23, 2024

Q Drum

Read SolutionImplemented by

Hans Hendrikse and Pieter Hendrisikse (Q Drum)

Updated on January 11, 2024

·Created on September 26, 2019

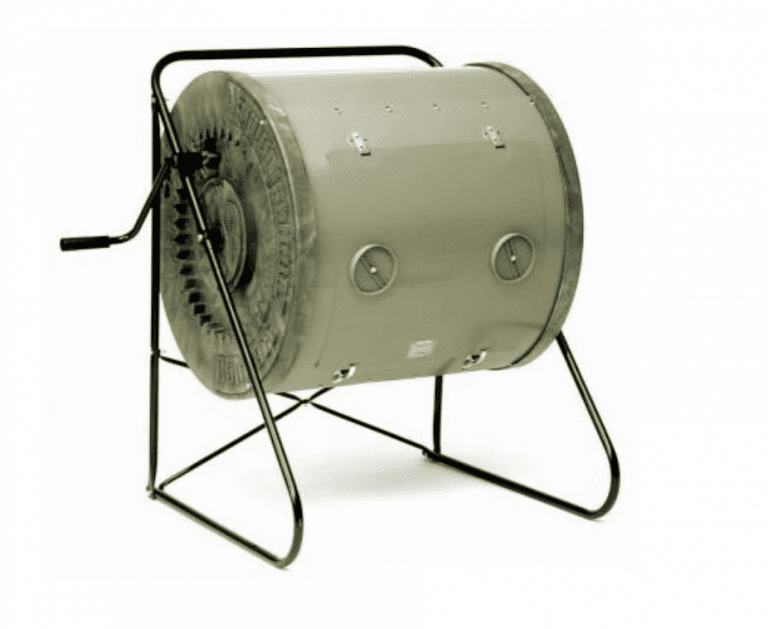

The rotary drum composter uses large amounts of ventilation to reduce composting time to 2–3 weeks.

Target SDGs

SDG 6: Clean Water and Sanitation

Market Suggested Retail Price

$300.00

Target Users (Target Impact Group)

Household, Community, Small and Medium-sized Enterprises, Public Sector Agencies

Distributors / Implementing Organizations

This product is available at retailers in India and in the USA.

Competitive Landscape

Direct competitors include Vermicomposting and NADEP Composting.

Regions

Worldwide

Manufacturing/Building Method

Manufactured by a number of distributors

Intellectural Property Type

Open-source

User Provision Model

Users obtain the product from different distributors.

Distributions to Date Status

Unknown

Input requirement (volume and frequency)

25 kg cow dung, 20 kg mixed vegetable waste, 10 kg saw dust, 5 kg compost (bulking agent), 1 time/20 days.

Additives

Saw dust, compost (bulking agent)

Production capacity (kg output per kg input)

~42 kg output per 60 kg input

Production duration

2-3 weeks

Percentage of nutrient recovery

2.1% nitrogen and 3.5% total phosphorus

Complementary treatment needed

None

Design Specifications

Rotary drum sizes my vary, but one study of a rotary drum composter used a 250 L capacity drum of 0.92 m in length and 0.9 m in diameter, made up of a 4 mm thick metal sheet. The inner side of the drum was covered by anti-corrosive coating and mounted on four rubber rollers attached to a metal stand. The drum is rotated manually.

40 mm angles are welded longitudinally inside the drum to mix the wastes, and two holes drain excess water. Waste should be shredded and placed inside at 70% of the total volume, with both half side doors of the drum open to allow additional aeration. Initial moisture content was around 61% and the cattle manure, mixed green vegetables and sawdust entered in a 2.5 : 2 : 1 ratio, on wet mass basis.

Technical Support

There is no technical support provided and users are expected to maintain the product on their own.

Replacement Components

None

Lifecycle

Unknown

Manufacturer Specified Performance Parameters

Rapid compost time of 2-3 weeks, pathogen inactivation, nutrient rich fertilizer.

Vetted Performance Status

The rotary drum composter was assessed for temperature, C/N ratio, TOC, coliforms, metals, turning frequency, and nutrient retention.

Safety

Implementers must take appropriate precautions when working with organic waste, particularly cattle manure, and ensure complete decomposition.

Complementary Technical Systems

None

Academic Research and References

Kalamdhad, A.S., Kazmi, A.A., 2008, Mixed Organic Waste Composting Using Rotary Drum Composter. International Journal of Environment and Waste Management, 2, pp. 24-36.

Kalamdhad, A.S., et al., 2009, Rotary drum composting of vegetable waste and tree leaves. Bioresource Technology, 100, pp. 6442-6450.

Kalamdhad, A.S., et al., 2008, Stability evaluation of compost by respiration techniques in a rotary drum composter. Resources, Conservation and Recycling, 52, pp. 829-834.

Villasenor, J., et al., 2011, Composting domestic sewage sludge with natural zeolites in a rotary drum reactor. Bioresource Technology, 102, pp. 1447-1454.

Singh, J., Kalamdhad, A.S., 2013, Assessment of bioavailability and leachability of heavy metals during rotary drum composting of green waste (Water hyacinth). Ecological Engineering, 52, pp. 59-69.

Kalamdhad, A.S., Kazmi, A.A., 2009, Effects of turning frequency on compost stability and some chemical characteristics in a rotary drum composter. Chemosphere, 74, pp. 1327-1334.

Varma, V.S., Kalamdhad, A.S., 2015, Evolution of chemical and biological characterization during thermophilic composting of vegetable waste using rotary drum composter. International Journal of Environmental Science and Technology, 12, pp. 2015-2024.

Compliance with regulations

Unknown

Evaluation methods

The rotary drum composter was assessed for temperature, C/N ratio, TOC, coliforms, and nutrient retention.

Other Information

Open source designs are available.

Agriculture

June 23, 2024

Implemented by

Hans Hendrikse and Pieter Hendrisikse (Q Drum)

Agriculture

January 17, 2024

Implemented by

Philippine Army

Agriculture

January 2, 2024

Implemented by

Toilets for People

Agriculture

August 13, 2024

Implemented by

Sun-Mar

Agriculture

December 18, 2023

Implemented by

Clivus Multrum

Agriculture

January 17, 2024

Implemented by

Narayan Deotao Pandharipande

Agriculture

August 16, 2024

Implemented by

EcoSwell

Agriculture

August 8, 2024

Implemented by

Patrick Kiruki, Banza Sanitation

Agriculture

February 4, 2024

Implemented by

Dhaara Smart

Agriculture

August 17, 2024

Implemented by

Roboterr Sewarage Construction

Have thoughts on how we can improve?

Give Us Feedback