Agriculture

January 24, 2024

AidGear Oasis-3 Water Purification System

Read SolutionImplemented by

AidGear

Updated on September 20, 2020

·Created on August 27, 2015

Shield 1000 Drinking Water Purification System is a LED-powered water purification unit.

The Shield 1000 is a water purification system designed by Puralytics which is useful for removing pathogens (bacteria, virus, protozoa), chemical contaminants (personal care products & pharmaceuticals), herbicides, and pesticides. The technology uses a photocatalytic nanotech fiber mesh to destroy contaminants in water. The Shield aims to improve humanitarian response by enabling access to safe drinking water while reducing water-borne diseases.

Target Users (Target Impact Group)

Distributors / Implementing Organizations

This product has been implemented by Roddenbery Disaster Response Team, and Puralytics.

Manufacturing/Building Method

The product is produced in batches to meet specific requirements. Interview with representative

Intellectural Property Type

Patent Protected

User Provision Model

This product is distributed by Puralytics (or another retailer), humanitarian organizations, governmental agencies, and non-profits to disaster relief and refugee settlements.Interview with representative

Distributions to Date Status

Unknown

Description of the combined methods

LED and nanotechnology mesh fiber

Manufacturer-specified water treatment rate (L/hr)

3154 L/hr

Bacteria reduction

6 log

Virus reduction

4 log

Protozoa reduction

4 log

Heavy metals and/or arsenic reduction

Yes, reduction rate unknown

Maximum recommended influent turbidity level (NTU)

Unknown

Effluent turbidity levels (NTU)

<5 NTU

Safe water storage capacity (L)

No

Manufacturer-specified lifetime volume (L)

150,000-340,000 L (Cartridge lifetime)

Consumables

Electricity

Design Specifications

The patented Puralytics® process employs LEDs to excite a nanotechnology mesh which purifies water following five-step light-activated purification processes. The five-step process includes:

The Shield sterilizes pathogens, eliminates chemical toxins, and removes heavy metals from the water. The system delivers 100% treated throughput which doesn't require chemical consumables and is scalable up to 100,000 liters per day.

Some of the technical specifications of the product include:

Technical Support

Technical support is provided by Pure Health Water, an authorized dealer of Puralytics. Interview with representative

Replacement Components

Some of the replaceable components for Field Shield 1000 includes;

Lifecycle

The LEDs will illuminate with full power for about 3 years. Replacements are only available if the products are shipped back to Puralytics. Interview with representative

Manufacturer Specified Performance Parameters

The designer specified performance targets include: 100% water recovery, removal of emerging contaminants (personal care products & pharmaceuticals), herbicides and pesticides, pathogens (bacteria, virus, protozoa), and industrial chemicals (petrochemicals, toxins) with no chemical consumables, and low generation of waste.

Vetted Performance Status

Unknown

Safety

Once a year maintenance schedule is recommended. The owner's manual provides detailed safety information.

Complementary Technical Systems

Activated carbon filter and ion-exchange technology. Interview with representative

Academic Research and References

Frederickson, J., 2014, Field Shield.

Chen, J. et al., 2003, Application of nano TiO2 towards polluted water treatment combined with electro-photochemical method, Water Research, 37(16), pp.3815-3820.

Rung, S., 2012, From Technology Push to Market Pull: Commercializing Nanoscience Research via Startups and Spinouts.

Laurance, J., 2016, Photocatalytic Treatment of Stormwater Runoff using Puralytics LilyPad.

Dossin Zanrosso, et al., 2020, Solution mixing preparation of PVDF/ZnO polymeric composite films engineered for heterogeneous photocatalysis, Journal of Applied Polymer Science, 137(9), p.48417.

Compliance with regulations

Meets US EPA Guidelines for Microbiological Water Purifiers Pathogen Reductions: Bacteria 99.9999%; Viruses 99.99%; Protozoa (cryptosporidium, giardia) 99.9%

Agriculture

January 24, 2024

Implemented by

AidGear

Agriculture

January 3, 2024

Implemented by

Easol Pvt Ldt

Agriculture

January 17, 2024

Implemented by

HACH

Agriculture

September 25, 2023

Implemented by

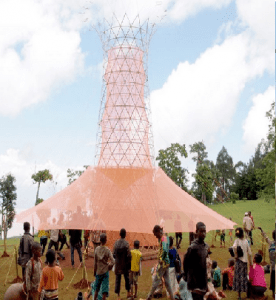

Gabriele Diamanti

Agriculture

August 4, 2024

Agriculture

January 8, 2024

Implemented by

JanaJal

Agriculture

January 11, 2024

Implemented by

Kohler

Agriculture

December 27, 2023

Implemented by

Katadyn Group

Agriculture

December 29, 2023

Implemented by

Sawyer

Agriculture

January 26, 2024

Implemented by

Warka Water

Have thoughts on how we can improve?

Give Us Feedback