Roy Ombatti turns sobering e-waste statistics around by using the waste to build salable 3D printers.

The world generates more than 40 million metric tons of e-waste each year according to a UN University report. And much of that winds up in developing countries where workers strip metals and other valuable materials from the parts, sometimes under dangerous conditions.

We see 3D printers as a revolutionary tool that can be used for development and this is what we are most curious and interested in.

Ombatti noticed that some of the waste in Nairobi was still operable. In 2015, shortly after graduating from a mechanical engineering program at the University of Nairobi, he founded African Born 3D Printing (AB3D) to build printers from tossed-out parts. Now he and his team at AB3D have built working prototypes and two dozen ready-for-sale printers. They have sold a dozen of them so far, and the newest models cost $400.

The printers are the first step in a larger business model. AB3D plans to begin printing shoes, prostheses and low-cost microscopes that will all be for sale or for donation to those in need who cannot afford them.

We asked Roy Ombatti five questions.

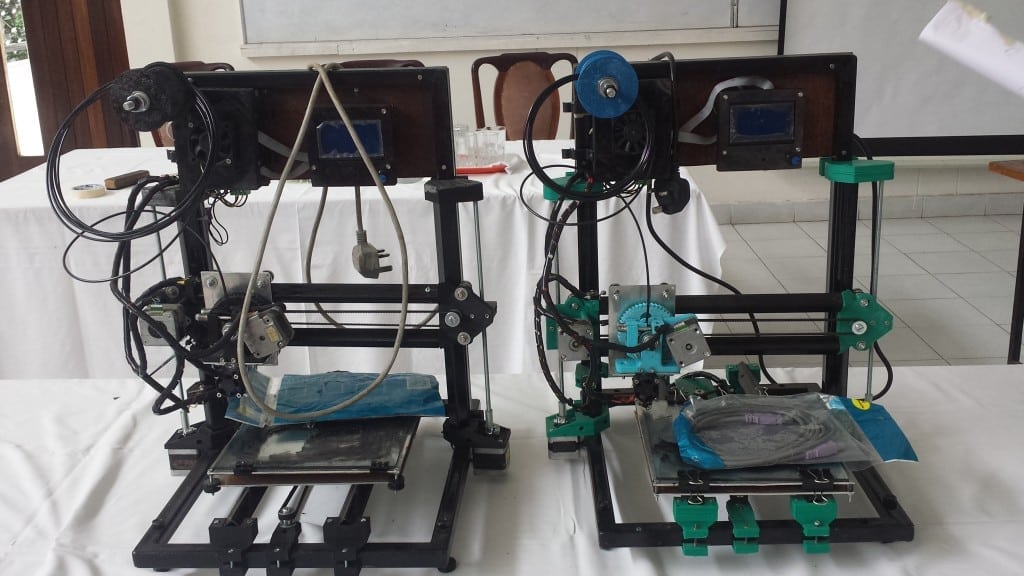

These 3D printers are made from e-waste and parts printed by 3D printers made from e-waste. Photo courtesy of Roy Ombatti

E4C: What is your vision for the printers in Kenya?

RO: We see 3D printers as a revolutionary tool that can be used for development and this is what we are most curious and interested in. We do not care much for the fun things that people print. We focus more on the functional products that will improve lives of the people living in poverty. We do not have the answers as to what people might print but we want to help make this happen by eliminating the barriers of uptake of this disruptive technology. As we identify the various use cases for our printers, our goal now is to get our printers into schools (all levels) since we see 3D printing as a powerful tool for education.

Our goal now is to get our printers into schools (all levels) since we see 3D printing as a powerful tool for education.

Broadly speaking, we want our printers to print solutions to some of the problems faced by Kenya and the greater developing world. For now we are making it our duty to try and make this technology catch on and we predict that with the right marketing of the products, there will be great demand from within Kenya. Kenyans generally like cool things and they are also very innovative. I suspect that the adoption of 3D printing will fair on well.

E4C: What kinds of electronic waste do you use when making a printer and where do you get it from?

We use motors from paper printers, photocopiers and scanners. We use fans and wires from most electronic waste and power supply units from servers.

For now the printers are similar for the most part. They only differ slightly due to the different motors that go into them. Unfortunately, I have no favorites. Like a good parent, I love my babies all the same!

E4C: What kinds of things have you printed so far?

Our printers are built out of printed parts so it’s interesting to print parts for another printer using a printer that was printed by an older printer.

Besides that we offer printing services so we have printed all sorts of things. We however intend to venture into prostheses this year.

As for the shoes, I have made numerous prototypes. Nothing has been released yet though.

E4C: Would you tell us about a time when you just knew that you’re in the right line of work?

RO: Uhm, for now I am fueled by the prospect of what we can achieve. I know in my heart that I am in the right line of work even though my mind might disagree, especially during periods of extreme ‘brokeness.’

I am supplying capital funds to a shoe maker near Kitale, and would be interested in PArtnering with you to use your 3d printer to make simple shoes for children in that area who are infected with jiggers. your happy feet work caught my attention.

Hello Roy,

I am the ED of a nonprofit organization who works with extraordinary NGOs in western Kenya. Is there a way we can get involved? We have just brought machinery into Kenya after completing a project in India making sanitary pads out of water hyacinth an invasive species and other agricultural wastes.

Shana Greene

What a great blog.When it comes to 3D printing, there are ways in which the technology can be employed. Keep writing such stuff.