Agriculture

February 20, 2024

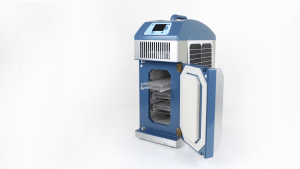

3rd Stone Design Stone Cold Solar

Read SolutionImplemented by

Stone Cold Systems

Updated on January 31, 2024

·Created on September 10, 2021

A moldable prosthetic socket

Amparo’s Confidence Socket is a moldable prosthetic socket that allows prosthetists to reshape multiple times to fit a wearer’s residual limbs as they naturally change shape.

Target SDGs

SDG 3: Good Health and Well-Being

Market Suggested Retail Price

$765.00

Target Users (Target Impact Group)

Household

Distributors / Implementing Organizations

It is distributed by Amparo directly and other partners like AT2030 Network, Global Disability Innovation Hub, Ottobock, and Amparo Access in a non-profit model.

Competitive Landscape

Direct competitors include AT-Knee and Jaipur Foot.

Regions

Africa, Europe, Latin America

Countries

Brazil, Germany, Kenya, South Africa, United Kingdom

Manufacturing/Building Method

Confidence Sockets are mass-produced in Berlin by Amparo and other empowered workshops in Kenya and South Africa. In a local process, the technician takes a negative plaster casting of the patient’s residual limb. Next, a positive model is created and modified to create a functional shape for bearing the patient’s weight. Then, a sheet of plastic is heated and draped over the positive model, and, using a vacuum system, the plastic is made to conform to the plaster shape. Finally, the attachment point for the rest of the prosthesis is connected and the rough edges are smoothed.

Intellectural Property Type

Trademark

User Provision Model

Users can acquire Confidence Sockets from Amparo.world store, AT2030 Network and Global Disability Innovation Hub, Ottobock, and Amparo Access in a non-profit model.

Distributions to Date Status

As of 2021, 2000+ pieces have been distributed around Europe, Africa, and Brazil, with majority of the distribution taking place in Germany.

Craftsmanship required

Yes

Patient satisfaction

Yes

Patient compliance

Yes. It was tested and validated

Comfort

Comfortable and moldable

Materials

Bioplastic polyester

Water resistant (yes/no)

Yes

Amputation level

Below the knee

Weight (kg)

200 – 800 g

Design Specifications

Confidence Socket is a moldable prosthetic socket that allows prosthetists to reshape multiple times to fit a wearer's residual limbs as they naturally change shape. In the make, it is a unique bioplastic polyester with a very low melting point, high melt viscosity, and high strength and stiffness at usage temperatures. The product was specially designed to be directly molded to the patient’s anatomy for creating final prostheses with ease. The Amparo Confidence Socket is only suitable for patients with transtibial amputations.

The manual contains more specific information.

It is not suitable for patients with:

Technical Support

Provided by manufacturer and partners like AT2030 through training workshops and exhibitions. This has been described as one key aspect to penetrating both the home and international markets. Further information can be found in the user manual provided and the user infocard. Ottobock professionals and Amparo also prepared a Step-by-Step tutorial.

Replacement Components

Replaceable components include: shuttle lock, valve, and pin lock-toothed.

Lifecycle

The Confidence Socket can be remolded up to 10 times before replacement.

Manufacturer Specified Performance Parameters

Amparo's aim was to create lower-limb sockets which are easy to fit, remoldable, and cost-effective long term. Providing confidence to restart a quality life for amputees across the world was the driving force to creating the Confidence Socket.

Vetted Performance Status

Amparo GmbH in collaboration with AT2030 Network and GDI Hub conducted a clinical trial for the confidence socket in Kenya at AIC CURE International Hospital Kenya (Kijabe, Kenya) and Association for the Physically Disabled of Kenya (APDK) (Mombasa, Kenya). Below-knee amputees aged 18 years and above were recruited for 6 months starting July 8th, 2019, and the clinical trial was completed on November 3oth, 2020. The findings have neither been entered into the National Institute of Health Clinical Trial registry nor been published in peer-reviewed journals since this research has just been completed.

Safety

The product's molding temperature is between 60-70?C but the insulation of a silicone liner between the plastic and limb ensures safe temperatures for the patient. The same process is currently used in several workshops in Europe and with approximately 50 patients currently using the product. In general, it has been shown to be safe and effective in creating below-knee prostheses. To ensure the safety of this product, Amparo GmbH conducted certified clinical trials.

Complementary Technical Systems

None

Academic Research and References

Williams, R., Oldfrey, B., and Holloway, C., 2020, “An AT Innovator case study: Amparo,” AT2030 Innovation Insights.

Ottobock. “Manual – Confidence Socket“, 2020.

Amparo. “Amparo Confidence Socket – Step-by-Step Tutorial.” YouTube, 2020.

National Institutes of Health. “Using Direct Molding Socket Technology for Trans-Tibial Prosthesis in Developing Regions.” Clinical trials, 2020.

Compliance with regulations

None

Evaluation methods

During the clinical trial in Kenya, the Amparo team measured Trinity Amputation and Prosthesis Scale (TAPES), Amputee Mobility Predictor, and the L-test on 27 participants with below-knee amputation.

Other Information

Started by students in 2014 as a University project, the team sought a unique approach to conduct a needs assessment in LMICs, particularly South Africa, and later evolved into a limited liability company Amparo. Amparo pivoted to establish a sustainable business in their home location of Germany (Berlin) first and later re-enter the LMIC market. To date, their leading product Confidence Socket is at the commercial level and they have penetrated several markets including; Germany, South Africa, Brazil, Kenya, United Kingdom, and Europe. For the LMIC’s, a non-profit called Amparo Access has been launched to improve access to their flagship product the confidence socket.

Agriculture

February 20, 2024

Implemented by

Stone Cold Systems

Agriculture

December 14, 2023

Implemented by

AFRIpads

Agriculture

December 2, 2024

Implemented by

BioLite

Agriculture

February 29, 2024

Implemented by

BRAC University

Agriculture

January 11, 2024

Implemented by

Caminos de Agua

Agriculture

January 17, 2024

Implemented by

Aquagenx

Agriculture

February 14, 2024

Implemented by

Diagnostics for all

Agriculture

September 23, 2023

Implemented by

Innovations for Poverty Action

Agriculture

November 10, 2023

Implemented by

Embrace Innovations

Agriculture

March 6, 2024

Implemented by

Project Prana Foundation

Have thoughts on how we can improve?

Give Us Feedback