Agriculture

June 11, 2024

6th Grain

Read SolutionImplemented by

6th Grain

Updated on January 30, 2024

·Created on October 30, 2018

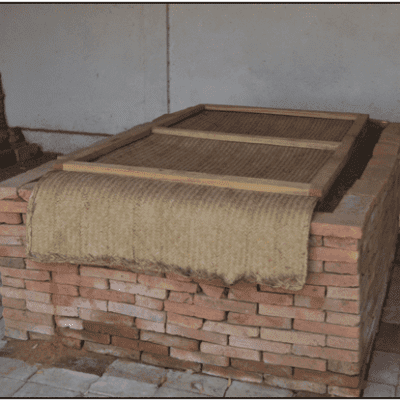

ECCs are large storage units made from local materials that keep vegetables and fruits at lower temperatures.

Evaporative cooling chambers (ECCs), also known as “zero energy cool chambers” (ZECCs), are simple and inexpensive systems that keep vegetables fresh without the use of electricity. These chambers can be made from locally available materials including bricks, sand, wood, dry grass, gunny/burlap sack, and twine.

Target SDGs

SDG 2: Zero Hunger

SDG 1: No Poverty

Market Suggested Retail Price

$100.00

Target Users (Target Impact Group)

Household, Community, Small and Medium-sized Enterprises

Distributors / Implementing Organizations

Open sourced technology, locally manufactured

Competitive Landscape

Direct competitors include Solar Powered Communal Refrigeration, Charcoal Cooler, and Zeer Pot.

Regions

Worldwide

Manufacturing/Building Method

Evaporative Cooling Chambers (ECCs) can be constructed from locally available materials such as bricks, sand, wood, dry grass, gunny/burlap sack, and twine. The chamber is constructed with two brick walls and the space in between the walls is filled with sand, which retains the water that is added. The ECCs should be constructed in a shaded area, under trees or a shed. For step-by-step instructions, see MIT D-Lab's Evaporative Cooling Best Practices Guide.

Watch this video on building an ECC, published by the World Vegetable Center.

Intellectural Property Type

Open-source

User Provision Model

Materials to construct ECCs are obtained/purchased locally. Units are built on-site by end-users or local builders.

Distributions to Date Status

Unknown

Storage capacity (L)

Sizing ranges from 500-5000 L

Time to cool (hr)

Depends on specific design and operating conditions

Cooling retention (hr)

Depends on specific design and operating conditions

Temperature control

No

Minimum internal temperature (°C)

Approximately 10-15 °C cooler than ambient temperature

Materials of construction

Bricks and sand with a cover made from wood, straw, or burlap

Protection from insect entry

Yes

Refrigeration cycle catalyst

Water should be added between the walls approximately once a day, depending on the evaporation rate

Design Specifications

Evaporative cooling chambers (ECCs) are double-walled storage containers that use evaporative cooling principles to reduce their internal temperature. Sand and water fills the space between the two brick walls. As the water evaporates outwards into the atmosphere, heat is removed from the inner wall, creating a cooling effect. Water can be added manually with a pitcher or via a gravity-fed dripper. ECCs have a larger capacity compared to household clay pot coolers and are designed for farmers, communities, or farming cooperatives.

Technical Support

ECCs designs are open-source. Technical support can be provided by the local manufacturer.

Detailed information regarding construction and use can be found in MIT D-Lab’s Evaporative Cooling Best Practices Guide.

Replacement Components

Replacement components, such as bricks, sand, and straw, are available locally.

Lifecycle

Approximately 3 years

Manufacturer Specified Performance Parameters

If the evaporative cooling chambers are operated in hot and dry climates (greater than 25 °C and less than 40% humidity) they can be expected to provide a storage environment with humidity greater than 80% and temperature at least 8 °C lower than the maximum daily ambient temperature.

Vetted Performance Status

MIT D-Lab conducted testing in Mali, in partnership with the World Vegetable Center. They reported that with a brick ECC storage, shelf life was up to 10 days for hot peppers and eggplant, 8 days for tomatoes, and 7 days for Okra, compared to only 2-4 days without cooled storage.

Safety

Possible contamination and spoilage of foods if not used properly.

Complementary Technical Systems

Clay pot coolers, or Zeer pots, operate on the same principle and provide a smaller, household storage capacity.

Academic Research and References

Verploegen, E., Sanogo, O., Chagomoka, T. Evaluation of Low-Cost Vegetable Cooling and Storage Technologies in Mali. 2018. Copyright ©Massachusetts Institute of Technology.

Kumar, R., Chandra, S., Samsher, Singh, B., Kumar, R., Kumar, A.A., Zero energy cool chamber for food commodities: A need of eco-friendly storage facility for farmers: A review. Journal of Pharmacognosy and Phytochemistry, 2018; 7(5): 2293-2301

Ambuko, J., Wanjiru, F., Chemining’wa, G.N., Owino, W.O., Mwachoni, E., Preservation of Postharvest Quality of Leafy Amaranth (Amaranthus spp.) Vegetables Using Evaporative Cooling. Journal of Food Quality. Volume 2017. Article ID 5303156, 6 pages.

Basediya, A. I., Samuel, D. V. K., Veera, V., Evaporative cooling system for storage of fruits and vegetables – A review. Journal of Food Science and Technology. 2013 Jun, 50(3):429-442.

Odesola, I. F., Onyebuchi, O., A review of porous evaporative cooling for the preservation of fruits and vegetables. The Pacific Journal of Science and Technology. 2009 Nov, 10(2):935-941.

Roy, S.K., On-farm storage technology can save energy and raise farm income. 1989. Amity Science, Technology & Innovation Foundation. Amity University Uttar Pradesh, India.

Compliance with regulations

Unknown

Other Information

Market suggested retail price depends on the cost of local materials.

MIT D-Lab testing in Mali

Produce spoilage causes disease and loss of income for needy farmers and venders who are forced to ‘rush sell’ most agricultural products, even though they are well aware of the negative impact flooding the market has on their profits. Even in towns and cities where erratic power supply is available, most of the urban poor cannot afford refrigerators.

MIT D-Lab's Evaporative Cooling Best Practices Guide

YouTube video on building an ECC,

Open source designs are available from several sources, including:

Evaporative cooling chambers are constructed locally and generally not tested before use. MIT D-Lab has conducted research on the performance of the open-source design in Mali.

Agriculture

June 11, 2024

Implemented by

6th Grain

Agriculture

August 29, 2024

Implemented by

Futurepump Ltd.

Agriculture

January 31, 2024

Implemented by

KickStart International

Agriculture

January 20, 2025

Implemented by

David Hughes

Agriculture

January 4, 2024

Implemented by

Promethean

Agriculture

January 22, 2024

Implemented by

Proximity Designs

Agriculture

August 29, 2024

Implemented by

Universidad del Valle de Guatemala (UVG)

Agriculture

January 6, 2025

Implemented by

Agribotix

Agriculture

June 11, 2024

Implemented by

AgEagle

Agriculture

September 19, 2024

Implemented by

Hydroponics Africa

Have thoughts on how we can improve?

Give Us Feedback

Thanks it’s a good thing for those without power from the grid

Can you use lava rock fill walls for the same effect? How thick would they need to be?