Agriculture

December 27, 2023

AquaFilter Family

Read SolutionImplemented by

Aquabox, UK

Updated on January 8, 2024

·Created on June 29, 2021

MAPET System (Manual Pit-latrine emptying technology) was a pushcart designed to empty existing pit latrines.

The MAPET System was a human-powered vacuum system made up of two separate systems. A pump operated by a hand piston pump and vacuum tank that are both mounted on a pushcart. This product has been discontinued and marked as a failure due to the inability to source parts and the high initial cost to purchase based on a review of pit latrine technologies.

Target SDGs

SDG 6: Clean Water and Sanitation

Market Suggested Retail Price

$3,000.00

Target Users (Target Impact Group)

Household, Community

Distributors / Implementing Organizations

WASTE

Competitive Landscape

Direct competitors include The Vacutug.

Countries

Tanzania

Manufacturing/Building Method

The components of the MAPET System were sourced in the Netherlands and then assembled in Tanzania.

Intellectural Property Type

Select Type

User Provision Model

The MAPET system was purchased from a partner NGO in hopes to set locals up in small businesses removing the fecal sludge from latrines.

Distributions to Date Status

Unknown

Toilet type

Latrine emptying

Evacuation method

Vacuum hand pump

Storage conditions

Raw

Capacity (L)

Unknown

Time until emptying

5 to 25 minutes

Design Specifications

There are two pieces of the MAPET system. The piston pump with the flywheel and the 200-litre vacuum tank. Each is mounted on a pushcart. A hose is connected to the tank and is used to suck the sludge from the pit. When the hand pump is turned, air is sucked out of the vacuum tank and sludge is sucked up into the tank. Depending on the consistency of the sludge, the MAPET can pump up to a height of 3 m.

Technical Support

There is no technical support provided and users are expected to maintain the product on their own.

Replacement Components

This product failed due to lack of availability of replacement components.

Lifecycle

Unknown

Manufacturer Specified Performance Parameters

The goal of the MAPET system was to provide individuals with the product and they would be able to manage their own fecal sludge removal business. The manufacturer also wanted to relieve issues associated with dependence on fossil fuels, demolition of slab, accessibility and local engagement.

Vetted Performance Status

Unknown

Safety

There were no known safety issues with this product.

Complementary Technical Systems

1. A mixing rod for stirring the waste

2. A hook for picking out waste that would block the suction hose

3. A shovel

4. A chisel and hammer for widening the squatting hole for the suction hose.

Academic Research and References

Mikhael, G., et al., 2014, Methods and Means for Collection and Transport of Faecal Sludge. Faecal Sludge Management: Systems Approach for Implementation and Operation. London: IWA Publishing, pp. 67-96.

Yoke, P.T., et al., 2009, Pit Latrine Emptying: Technologies, Challenges and Solutions. EWB – UK Research Conference, 2009.

Compliance with regulations

Unknown

Evaluation methods

Unknown

Other Information

A report from IRC WASH that discusses the MAPET System.

Agriculture

December 27, 2023

Implemented by

Aquabox, UK

Agriculture

January 11, 2024

Implemented by

Kenya Ceramic Project (KCP)

Agriculture

January 2, 2024

Implemented by

Katadyn Group

Agriculture

January 16, 2024

Implemented by

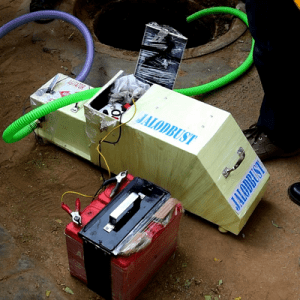

Jalodbust

Agriculture

August 16, 2024

Implemented by

Wetlands Work

Agriculture

January 15, 2024

Implemented by

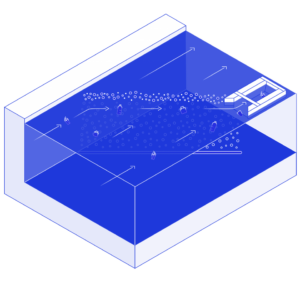

The Great Bubble Barrier

Agriculture

January 27, 2024

Implemented by

Water and Environmental Engineering, University of Bristol

Agriculture

February 2, 2024

Implemented by

Glanris

Agriculture

August 16, 2024

Implemented by

Sanitation First India

Agriculture

February 5, 2024

Implemented by

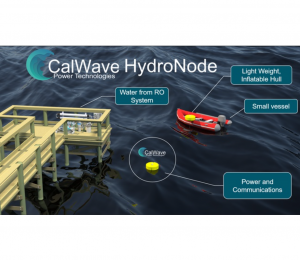

CalWave

Have thoughts on how we can improve?

Give Us Feedback