Agriculture

January 17, 2024

mWater Field Test Kit

Read SolutionImplemented by

mWater

Updated on January 16, 2024

·Created on September 9, 2020

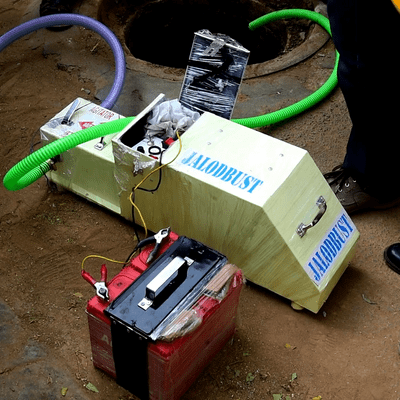

The Jalodbust sludge remover is a portable, battery-powered, sanitary sludge handling device designed to work as a sewage pump, agitator and declogger.

The Jalodbust sludge remover is a portable, battery-powered, sanitary sludge handling device with an agitator. It is designed to dislodge, liquefy and remove faecal sludge from leach pits, septic tanks and manholes with the intent to replace human handling of wastes. A differentiator is its ability to remove settled and hardened sanitary sludge.

Target SDGs

SDG 6: Clean Water and Sanitation

Market Suggested Retail Price

$1,000.00

Target Users (Target Impact Group)

Community, Small and Medium-sized Enterprises

Distributors / Implementing Organizations

Jalodbust is presently manufacturing the product which is planned to be mass-produced in 2020.

Competitive Landscape

Direct competitors include The Vacutug and The Gulper.

Countries

India

Manufacturing/Building Method

The product is presently under product manufacturing design in India, and is planned to be mass-produced in 2020.

Intellectural Property Type

Patent

User Provision Model

Users can obtain the product from Jalodbust.

Distributions to Date Status

The manufacturer is aiming to launch the product in the market on 1st July 2020.

Currently, Jalodbust sludge remover has been used in a number of field trials in Weavers Colony, Thannisandra, and Yashwantpur, Bengaluru.

Emptying speed (L/min)

9 – 14 L/min

Accessories needed

Containers for sludge collection, PPE for operators

Transport mechanism

N/A

Transport speed (km/hr)

N/A

Storage volume of transportation (L)

N/A

Design Specifications

The Jalodbust sludge remover uses a battery-powered agitator and sewage pump to extract sludge from septic tanks into a collection container.

This product (Jalodbust-Pride) is a portable model designed for emptying only. The operator will need to facilitate the transportation and emptying of collection containers after extraction.

The product specifications are as follows:

Technical Support

The manufacturer is regularly in touch with target user groups to obtain feedback prior to launching product to market. Correspondence with designer

Replacement Components

Spare parts are provided through the manufacturer's marketing and service channels. Correspondence with designer

Lifecycle

The manufacturer indicated they need to perform further tests on the product durability and lifecycle. Correspondence with designer

Manufacturer Specified Performance Parameters

General performance targets include its usability in confined and narrow spaces, portability, affordability, and ability to remove settled and hardened sanitary sludge with minimal human contact.

Vetted Performance Status

Lab testing and field trials have been undertaken for the Jalodbust sludge remover. Jalodbust conducted field trials in Bengaluru, India on sewer manholes and leach pits in the presence of sanitation workers. The field trials demonstrated the product's ability to:

Safety

The operator should not come into contact with the faecal sludge and must dispose of it according to regulations. Personal protective equipment should include at least a protective suit, face mask, waterproof boots, gloves, and safety goggles for the operator.

Complementary Technical Systems

Containers for sludge collection and its transportation between sites is separately procured by the user.

Academic Research and References

Pranjali, 2020, The story behind JALODBUST – An initiative to make manual scavenging accessible, Times Next.

Compliance with regulations

The manufacturer stated that the following tests need to be performed on production samples for safety and/or regulations: water splash test, electronic control unit testing, operation of loT function and dashboard interface, chocking and dry run performance parameters, product durability and lifecycle. Correspondence with designer

Evaluation methods

The product was self-evaluated by the organisation using product testing and user feedback. This includes portability, corrosivity, and abrasion resistance of materials used to construct the device.

Other Information

Agriculture

January 17, 2024

Implemented by

mWater

Agriculture

December 7, 2023

Implemented by

SPOUTS of WATER

Agriculture

August 13, 2024

Agriculture

January 3, 2024

Implemented by

Cascade Designers, Inc

Agriculture

January 17, 2024

Implemented by

Kärcher Futuretech

Agriculture

January 10, 2024

Implemented by

SOURCE

Agriculture

January 16, 2024

Implemented by

NVterra

Agriculture

December 7, 2023

Implemented by

Envirogard Products Ltd

Agriculture

December 29, 2023

Implemented by

Pure Hydration

Agriculture

August 21, 2024

Implemented by

Illuminum Greenhouses Kenya

Have thoughts on how we can improve?

Give Us Feedback