Agriculture

November 30, 2024

El Fuego del Sol Recycled Briquettes

Read SolutionImplemented by

El Fuego del Sol

Updated on January 2, 2024

·Created on May 22, 2016

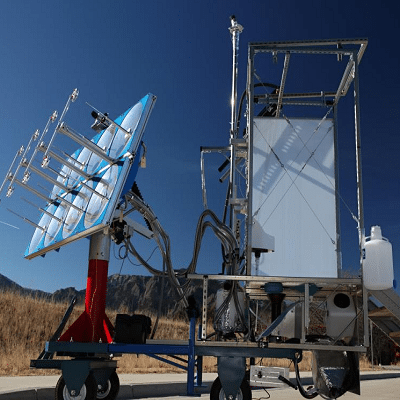

The Sol Char Toilet uses solar power to convert waste into charcoal and fertilizer.

The Sol-Char Toilet is a prototype toilet system with user interface, storage, and treatment. Parabolic dishes concentrate sunlight and convert it to heat that is used to disinfect excreta and make charcoal and fertilizer from it. An introductory video to the prototype is found here.

The prototype needs sunlight to function properly, hence regions with high sunlight are mainly targeted. It is constructed to operate off-sewer, to allow functionality in water scarce regions (often coinciding with sunny regions). In prototype phase 1, the toilet was laboratory tested. A field pilot is part of the planned phase 2.

Target SDGs

SDG 6: Clean Water and Sanitation

SDG 11: Sustainable Cities and Communities

Market Suggested Retail Price

$11,000.00

Target Users (Target Impact Group)

Household, Community, Small and Medium-sized Enterprises

Distributors / Implementing Organizations

This product has been implemented by the University of Colorado Boulder, Sol-Char research team.

Regions

Worldwide

Manufacturing/Building Method

The Sol-Char Phase I prototype is constructed with industrial-grade materials: aluminum for the metal and optical components, stainless steel for the reactor components, and industrial steel and plastic for the user compartment. However, a functional prototype could be constructed more economically. The fiber optic cables are the most expensive component and outsourcing is currently in development. The majority of the Sol-Char toilet materials could be constructed in a local machine shop using more affordable materials such as concrete, spun aluminum, and injection-molded plastic. For example, the carousel drive that rotates the reactors can be constructed out of recycled bicycle parts and scrap metal.

Intellectural Property Type

Trademark

User Provision Model

The Sol-Char Toilet is still a prototype so it is not provided to users yet, but the product characteristics open up for several options of user provision. The toilet could be bought directly from the manufacturer/retailer or rented as a service. In low-income, NGOs or governmental agencies may finance a larger system with several toilets for a community. Another option is that a company provides the toilet to the public and the user pay a fee for each use.

Distributions to Date Status

One prototype has been developed so far at the University of Colorado Boulder. Phase 2 of the project consists of field tests.

Toilet type

Toilet

Evacuation method

Pour flush

Storage conditions

Container storage

Capacity (L)

4 L

Time until emptying

Processes 2 kg feces in 4 hours sunshine (converts to charcoal)

Design Specifications

The prototype was designed to process 2 kg of feces and 4 kg of urine with 4 hours of sunshine (given that fecal char has an energy content of 25.6 MJ/kg). The product concentrates sunlight and transfers energy to fiber optic bundles located at the focus of parabolic concentrators. The concentrated solar power illuminates the containers (both "collection" and "reaction" chambers) and disinfects the waste through conduction, convection, and radiation heat transfer. The reactor is designed to achieve temperatures between 300 °C - 750 °C and produces a safe and usable product.

Technical Support

Technical support is provided directly by the manufacturer, the Sol-Char team.

Replacement Components

Replacement components can be hard to find locally in the Global South if the prototype materials are used. There are ways to simplify the construction and use materials available in most contexts such as scrap metal, concrete and bicycle parts. Some parts will need to be specially ordered such as the optic fibers which are the most expensive part of the system.

Lifecycle

20 years

Manufacturer Specified Performance Parameters

Performance targets include creating an affordable product that operates off-grid, without piped water or sewage. In addition, the treatment of human waste should create useful outputs. The Sol Char is expected to produce 80 g charcoal/use/day and 1 L of treated urine/person/day.

Vetted Performance Status

The reactor is designed to achieve high temperatures (300 to 750 °C) and produce safe and usable products. In experiments conducted on the toilet, waste was reduced by 85-92% of the original mass (85% corresponds to pyrolyzing at 300 °C and 92% for pyrolysis at 750 °C).

Safety

Manual hand cranks can be used if the automated flush mechanism fails so contact with fecal matter is still avoided. Dilution and adsorption is used to reduce human contact to exhausts. Exhausts are done through a pipe 2.5 m above ground. All moving parts are shrouded, and fibers are made so that light only exits within 8" (fire precautions only have to be taken in this range). Pathogens are killed in the charring process to ensure that the system is hygienic.

Complementary Technical Systems

Electrical 'co-generation' provides up to 15 kW-hrs of electricity with battery backup for offline (cloudy) operation.

Academic Research and References

Ward, B. J., et al., 2014, “Evaluation of Solid Fuel Char Briquettes from Human Waste“, Environmental Science and Technology, 48, pp. 9852-9858.

2014, “Reinventing the toilet for 2.5 billion in need“, Bulletin World Health Organisation, 92, pp. 470–471.

Garcia-Fine, S., 2015, “Redesign of the Sol-Char Toilet“, Bachelor dissertation, Worcester Polytechnic Institute, Worcester, Massachusetts.

Compliance with regulations

The product has been developed to comply with safety standards and environmental regulations so that it can be implemented in diverse contexts.

Evaluation methods

The product has been developed and evaluated continuously through iterative prototyping.

Other Information

Sol-Char sanitation media can be viewed here. In addition, an extensive amount of published articles have covered the Sol-Char project. Several conference posters are also available. The Sol-char sanitation team is exploring a phase 2 design for a field pilot.

Additional research articles and presentations conducted by the University of Colorado research team can be viewed here. Topics include Solar Thermal Design & Modeling, Biochar Fuel & Emissions, Biochar Applications in Agriculture, Odor & Exhaust, and Disinfection.

Agriculture

November 30, 2024

Implemented by

El Fuego del Sol

Agriculture

January 19, 2024

Implemented by

Clean Team Ghana

Agriculture

August 8, 2024

Implemented by

Patrick Kiruki, Banza Sanitation

Agriculture

January 22, 2024

Implemented by

Sanivation

Agriculture

December 13, 2023

Implemented by

change: Water

Agriculture

August 13, 2024

Implemented by

The Africa Trust

Agriculture

December 18, 2023

Implemented by

Clivus Multrum

Agriculture

August 13, 2024

Implemented by

Indian Institute of Technology (IIT) Bombay

Agriculture

January 17, 2024

Implemented by

Centro de Desarrollo del Habitat y el Medio Ambiente (CEDES/Habitat)

Agriculture

August 13, 2024

Implemented by

LEHO SAS

Have thoughts on how we can improve?

Give Us Feedback