Agriculture

December 20, 2023

Laveo Dry Flush Toilet

Read SolutionImplemented by

Dry Flush

Updated on January 6, 2024

·Created on October 1, 2018

The Sulabh Flush Compost Toilet is a two-pit and pour-flush household toilet consisting of a squatting pan.

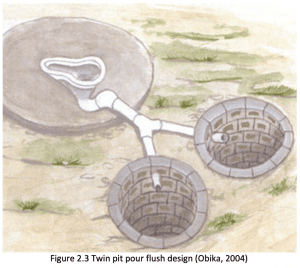

The Sulabh toilet is a twin-pit system which composts waste on-site. The two leach pits retain solid matter and allow the liquid to leach and gases to disperse into the ground. Once one pit is filled, waste is diverted to the second pit. This dual-system allows adequate time for the waste to decompose into fertilizer.

The toilet system is available in 11 models, with costs ranging from 31 – 275 USD.

Target SDGs

SDG 6: Clean Water and Sanitation

Market Suggested Retail Price

$275.00

Target Users (Target Impact Group)

Household, Community, Public Sector Agencies

Distributors / Implementing Organizations

This toilet system is manufactured and implemented by the Sulabh International in coordination with local government authorities when constructing community toilets.

Competitive Landscape

Direct competitors include Twin Pits for Pour Flush, DuraSan Latrine, Easy Latrine, Elephant Toilet, and Fossa Alterna.

Countries

India

Manufacturing/Building Method

The pits are constructed with locally available materials including bricks, cement, and wood.

Intellectural Property Type

Trademark

User Provision Model

Sulabh International delivers and installs toilets directly for users. In low-income communities, the organization partners with local government authorities for financing.

Distributions to Date Status

1.2 million residences and building have implemented Sulabh toilets.

Toilet type

Pit latrine

Evacuation method

Pour flush

Storage conditions

Pit

Capacity (L)

~736-2344 L Depending on circular pit dimensions

Time until emptying

~2-3 years

Design Specifications

The Sulabh Flush Compost Toilet is designed as a two-pit system to ensure that one could be used continuously to contain waste while the second allows waste to decompose and become fertilizer. The toilet pan has a steep slope (25°-28°) and the plumbing uses a water-seal (20 mm) to prevent odours. Water conservation was considered during the design, so each flush only requires 1 - 1.5 liters of water. The two pits are sized based on the number of users, designed with a lifetime of 3 years of use per pit.

Technical Support

Operation and maintenance is performed by Sulabh and funded through a pay-per-use model, while maintenance in low-income areas is cross-subsidized with income from the toilets in wealthier, busier areas.

Replacement Components

Replacement components are provided by the manufacturer when needed during maintenance.

Lifecycle

Each pit is designed to be filled for 2-3 years. If the dual-pits are emptied and used effectively, the toilet is expected to operate for an extended period (with pits reported to operate for 40 years).

Manufacturer Specified Performance Parameters

The manufacturer has specified performance targets related to constructability in varied environments, minimal health and environmental hazards, easy maintenance, less space needed than a septic tank toilet system, and elimination for the need of scavengers to clean the pits.

Vetted Performance Status

An assessment was performed by the United Nations Development Program (UNDP) in 2006 to assess the operation, impact and financing of Sulabh International within the context of the sanitation landscape in India. This included an examination of the organisation's mode of operation, its impact on health and hygiene, and the eradication of scavenging.

Safety

If the pits are not constructed properly and well-sealed, there is the possibility of groundwater contamination. In addition, the time needed for waste digestion before it becomes pathogen-free is still debated. Furthermore, the product is deemed not applicable in hard rock environments due to potential groundwater contamination.

Complementary Technical Systems

As the toilets are designed for pour-flushing, a water source needs to be implemented nearby to allow for continual water usage. Secondary treatment can also be considered.

Academic Research and References

Srinivas, V., Chary, A., Narender, K. Rao, R., 2003, Serving the poor with sanitation: the Sulabh approach, 3rd World Water Forum, PPCPP Session.

Jha, PK., 2004, Health and social benefits from improving community hygiene and sanitation: an Indian experience, International Journal of Environmental Health Research, 13: 133-140.

Chary, S. et al., 2003, Pay-and-use toilets in India, Waterlines, 21(3).

Ramani, S., Ghazi, S., Duysters, G., 2012, On the diffusion of toilets as bottom of the pyramid innovation: Lessons from sanitation entrepreneurs, Technological Forecasting and Social Change 79(4): 676-687

Wagner, E., Lanoix, J. & World Health Organization, 1958, Excreta disposal for rural areas and small communities. World Health Organization.

Mughal, F.H., 2013, Do pour flush toilets produce a pathogen free sludge (twin pit alternating)?, SuSanA Forum.

Compliance with regulations

The toilets meet each of the seven conditions of a sanitary latrine presented by the World Health Organization (page 39 of document).

Evaluation methods

The toilets and produced fertilizer have been evaluated by a group of volunteers (technocrats, managers, scientists, engineers, doctors, and architects) for their structural performance and health impact.

Other Information

Sulabh and its founder, Dr. Bindeshwar Pathak, have been awarded several awards over the past 40 years including the Padma Bhushan (1991), the International Saint Francis Prize for the Environment-“Canticle of All Creatures” (1992), the Bombay Citizen’s Award (1992), the Indira Gandhi Priyadarshini Award (1994), the Babu Jagjivan Ram Award for abolishing scavenging (1997), and the Indira Gandhi Paryavaran Award (2003).

Sulabh: How it Works

Agriculture

December 20, 2023

Implemented by

Dry Flush

Agriculture

January 19, 2024

Implemented by

Clean Team Ghana

Agriculture

February 16, 2024

Implemented by

Agpulse Organics Pvt Ltd, Mr. Rajeev Ranjan

Agriculture

January 4, 2024

Implemented by

Envirosan

Agriculture

January 6, 2024

Implemented by

Sustainable Sanitation and Water Management (SSWM)

Agriculture

August 8, 2024

Implemented by

Patrick Kiruki, Banza Sanitation

Agriculture

August 13, 2024

Implemented by

The Africa Trust

Agriculture

August 17, 2024

Implemented by

Sanergy

Agriculture

August 13, 2024

Implemented by

Sun-Mar

Agriculture

January 17, 2024

Implemented by

Centro de Desarrollo del Habitat y el Medio Ambiente (CEDES/Habitat)

Have thoughts on how we can improve?

Give Us Feedback