Agriculture

January 16, 2024

Living Water Treatment Systems

Read SolutionImplemented by

George Greene III, PE, PhD

Updated on January 12, 2024

·Created on October 1, 2020

The Living Machine is a form of ecological sewage treatment that mimics a natural wetland system, marketed by Living Machine Systems, L3C.

The Living Machine is a form of ecological sewage treatment based on the principles of wetland ecology, pioneered by US ecological designer Dr. John Todd in the 1970’s. The Living Machine is designed and marketed by Living Machine Systems, L3C in Charlottesville, VA, USA. The Living Machine uses engineering, plants, and bacteria to efficiently treat and reuse wastewater.

Target SDGs

SDG 6: Clean Water and Sanitation

Market Suggested Retail Price

$1,000,000.00

Target Users (Target Impact Group)

Community, Small and Medium-sized Enterprises, Public Sector Agencies

Distributors / Implementing Organizations

This product is distributed by Living Water Systems, L3C.

Competitive Landscape

Direct competitors include AnoxKaldnes Moving Bed Biofilm Reactor, Sequential Batch Reactor, Membrane Biofilm Reactor, and Decentralized Wastewater Treatment Systems (DEWATS).

Regions

Worldwide

Manufacturing/Building Method

Unknown

Intellectural Property Type

Trademark

User Provision Model

This product can be acquired by contacting the manufacturer.

Distributions to Date Status

The exact number of distributions is unknown, however, Living Machine Systems, L3C state the Living Machine System has been installed in 30 locations globally.

Flow rate (L/min)

105.15 to 2628.76 L/min. Flow rate is dependant on site specifications.

Power Supply Type

Electrical

Technology type

Sedimentation, filtration, clarification, adsorption, nitrification/denitrification, volatilization and anaerobic and aerobic decomposition.

BOD Removal Efficiency

97%

COD removal efficiency

94%

NH4-N Removal Efficiency

94-98%

TSS removal efficiency

97-98%

Total Phosphorus Removal Efficiency

45-67%

Fecal Coliform Removal Efficiency

99.9%

Design Specifications

The Living Machine is made up of several components to mimic the process of natural coastal wetlands. The patented tidal-flow technology pumps wastewater into ‘tidal-flow’ wetland cells (gravel filled planters) which are flooded and drained to oxygenate the wastewater. The process is as follows:

Technical Support

Provided by the manufacturer.

Replacement Components

Unknown

Lifecycle

Unknown

Manufacturer Specified Performance Parameters

The manufacturer specifies the following as performance targets:

The Living Machine is capable of tertiary treatment, which requires low costs to operate and doesn’t require chemicals that are harmful to the environment.

Vetted Performance Status

The US EPA has tested the use of constructed wetland technology performance for BOD (<30 mg/L) and TSS (<30 mg/L) removal.

Safety

Wastewater must be handled, treated and disposed of in accordance with hygiene and environmental standards before reuse.

Complementary Technical Systems

The Living Machine is a modular system. Additional wastewater treatment modules and storage can be implemented to meet the site requirements.

Academic Research and References

Austin, D., 2006, Influence of cation exchange capacity (CEC) in a tidal flow, flood and drain wastewater treatment wetland, Ecological Engineering 28: 35-45.

Behrends, L., et al., 2007, Integrated constructed wetland systems: design, operation, and performance of low-cost decentralized wastewater treatment systems, Water Science Technology 55: 155-161.

Austin, D., Nivala, J., 2009, Energy requirements for nitrification and biological nitrogen removal in engineered wetlands, Ecological Engineering 35: 184-192.

O’Connel, K. A., 2011, Ecologically Inspired, Architect.

Compliance with regulations

The Living Machine is in compliance with US EPA, EPA/625/R-99/010 standards for constructed wetlands treatment of municipal wastewaters.

Evaluation methods

Living Machine cites high quality treated water for reuse as evaluation criteria.

Other Information

Agriculture

January 16, 2024

Implemented by

George Greene III, PE, PhD

Agriculture

August 14, 2024

Implemented by

Esther Mwangi, EsVendo

Agriculture

February 26, 2024

Implemented by

Advanced Earthen Construction Technologies (AECT)

Agriculture

February 1, 2024

Implemented by

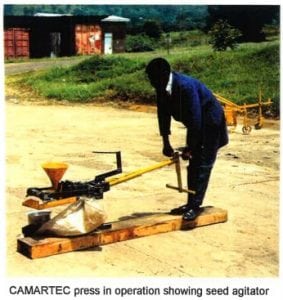

Centre for Agricultural Mechanization and Rural Technology (CAMARTEC)

Agriculture

February 5, 2024

Implemented by

Gradian Health Systems

Agriculture

February 1, 2024

Implemented by

Lifeway Solar

Agriculture

February 16, 2024

Implemented by

Dairy Dynamics

Agriculture

December 27, 2023

Implemented by

Aquabox, UK

Agriculture

January 11, 2024

Implemented by

Kenya Ceramic Project (KCP)

Agriculture

January 19, 2024

Implemented by

Clean Team Ghana

Have thoughts on how we can improve?

Give Us Feedback