Suggested Articles

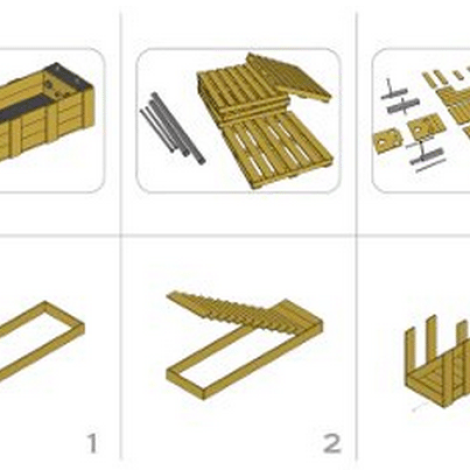

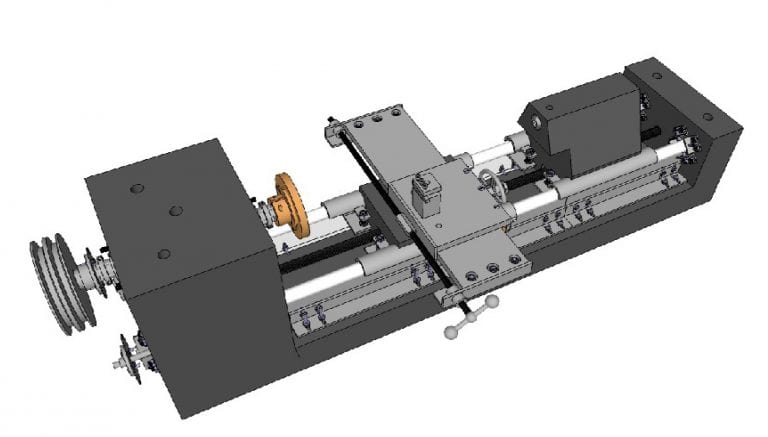

Finished! A construction manual for an open-source, low-cost screw-cutting lathe

General

Update June 2022: Removed bad links and information. The duo behind the Yeoman’s concrete lathe for the 21st century has completed an illustrated construction guide (pdf). Pat Delany, an...