Agriculture

December 27, 2023

AquaFilter Family

Read SolutionImplemented by

Aquabox, UK

Updated on January 12, 2024

·Created on June 19, 2016

Biopipe is a wastewater treatment system that recycles water for irrigation and secondary applications.

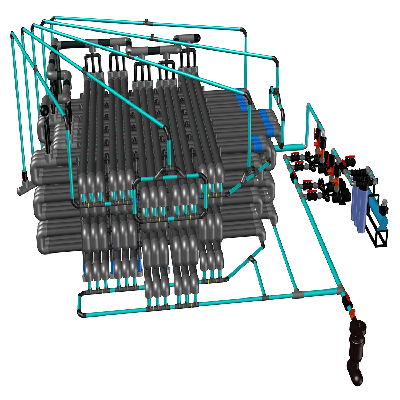

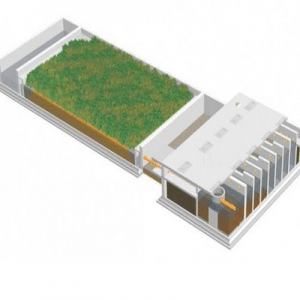

Biopipe is a decentralized wastewater treatment pipe network that treats domestic wastewater for reuse in irrigation and secondary use applications. The system is comprised of a tank, pipe modules, circulation and water pumps, and a UV filter. Microbiological pathogens are removed by bacteria that lines the inside of the pipe. Biopipe can also be scaled up to accommodate the treatment demands of large cities.

Target SDGs

SDG 6: Clean Water and Sanitation

Target Users (Target Impact Group)

Household, Community

Distributors / Implementing Organizations

The product has distributors across the globe. These include Environest (India), BPipe (Philippines), Abrimix Ltd (South Africa), Pureland LLC (California), Biotech Innovations (Bangladesh), Biopipe (Ethiopia).

Competitive Landscape

Direct competitors include Decentralized Wastewater Treatment Systems (DEWATS) and The Biofil Digester.

Countries

Bangladesh, Egypt, Ethiopia, India, Maldives, Morocco, Oman, Qatar, South Africa, Turkey, United Arab Emirates, United States

Manufacturing/Building Method

Biopipe uses PVC pipes, tanks, and pumps to allow for a flexible and modular design to fit specific needs.

Intellectural Property Type

Patent

User Provision Model

Users can obtain the product by contacting the manufacturer directly, or through their local distributing office.

Distributions to Date Status

As of 2020, approximately 40 units have been implemented.

Flow rate (L/min)

Batch system: 0.69 L/min

Power Supply Type

Electrical

Technology type

Aerobic decomposition, UV filtration

BOD Removal Efficiency

97%

COD removal efficiency

95%

NH4-N Removal Efficiency

96%

TSS removal efficiency

99%

Total Phosphorus Removal Efficiency

Unknown

Fecal Coliform Removal Efficiency

99%

Design Specifications

In a Biopipe system, a sewage tank is used to store inorganic waste and wastewater. When an operational level is reached, a pump separates organic materials from wastewater, and wastewater is circulated. Once the Biopipe is full, bacteria are engaged on the pipe walls. Air is passively vacuumed by a pressure differential to facilitate aerobic decomposition. The wastewater then passes through a cartridge/mechanical filter and a UV filter. Biopipe can treat the wastewater generated by small buildings to cities of millions; Biopipe brings energy consumption to a minimum as it can store wastewater in a horizontal position which better distributes water pressure and requires less energy. Biopipe's water treatment always for recycling of water for secondary purposes like irrigation or toilet water.

Technical Support

Provided by the manufacturer in the form of an annual maintenance plan.

Replacement Components

Contact the manufacturer for replacement components.

Lifecycle

Biopipe guarantees a wastewater treatment system good for life and warranted by an annual maintenance agreement.

Manufacturer Specified Performance Parameters

Performance targets include Biopipe producing no sludge, no odor, no sound, and no waste; no added chemicals are required to operate the Biopipe wastewater treatment system; no noise pollution.

Vetted Performance Status

Bangladesh University of Engineering and Technology conducted a water test report, finding effective removal of coliforms, TSS, TDS, BOD5, by <99%.

Safety

No known safety hazards are related to this product.

Complementary Technical Systems

Fully automated controls to be operated from remote locations.

Compliance with regulations

According to the designer, Biopipe meets international and EU standards.

Evaluation methods

The product is evaluated for the removal of total suspended and dissolved solids, coliforms, nitrates, and chemical oxygen demand.

Agriculture

December 27, 2023

Implemented by

Aquabox, UK

Agriculture

December 22, 2023

Implemented by

Allspeeds

Agriculture

January 11, 2024

Implemented by

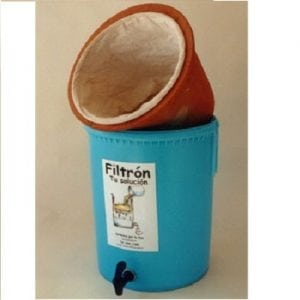

Potters for Peace

Agriculture

January 11, 2024

Implemented by

Cleanbodia

Agriculture

December 19, 2023

Implemented by

AquaSanTec

Agriculture

January 11, 2024

Implemented by

BORDA

Agriculture

December 20, 2023

Implemented by

Enviro Loo

Agriculture

December 20, 2023

Implemented by

GARV Toilets

Agriculture

January 3, 2024

Implemented by

Grundfos

Agriculture

January 10, 2024

Implemented by

NativeEnergy

Have thoughts on how we can improve?

Give Us Feedback