Agriculture

August 21, 2024

SAECSA Solar Food Dryer

Read SolutionImplemented by

SAECSA

Updated on August 21, 2024

·Created on May 23, 2016

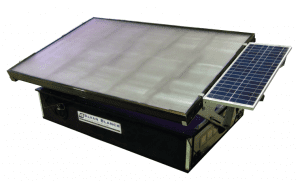

Calphijo Enterprises Solar Dryer is a fruit and vegetable dryer used during post harvest stage.

Claphijo Enterprises Solar Dryer is a fruit and vegetable dryer completely powered by solar energy. The system uses heat of the sun to reduce the moisture content of a product (fresh fruits, vegetables, meat, fish), while drying causes minimum damage to the product.The solar dryer aims to improve food security in Tanzania. The solar dryer comes with two pots, is easily portable, and is made from local wood, a plastic sheet and wire mesh.

Prices range according to sizes from USD 300 to 700 per unit/piece Interview with manufacturer, that is to say from Tsh 650,000 to 1,500,000.00 (June 2016).

One dryer could be operated by an entrepreneur that buys fruit from local farmers. The solar oven helps women to save a substantial amount each month on what they would have paid for electricity.

Target SDGs

SDG 2: Zero Hunger

SDG 7: Affordable and Clean Energy

Market Suggested Retail Price

$700.00

Target Users (Target Impact Group)

Small and Medium-sized Enterprises

Distributors / Implementing Organizations

Claphijo Enterprises distributes the solar dryers. The company tested prototypes in three villages and trained farmer groups on how to use the drier.

Competitive Landscape

Direct competitors include SunWorks Solar Food Dryer.

Regions

East Africa

Countries

Kenya, Tanzania

Manufacturing/Building Method

Manufactured on a per-demand basis.

Intellectural Property Type

Select Type

User Provision Model

The sun dryer can be purchased from Claphijo Enterprises.

Distributions to Date Status

Distribution started two years ago and to date, Claphijo Enterprises have sold more than 15 driers.Interview with manufacturer About 350 farmers have been engaged to date.

Drying capacity (lbs/m³)

Unknown.

Drying duration (hr)

2-3 days for the food to dry, depending on the sun.

Load capacity (m³)

Unknown.

Operating temperature range (°C)

Up to 220°C.

Temperature control

No

Materials of construction

Wood and plastic mesh

Design Specifications

The following take place in the solar dryer in order to dry a product:

Technical Support

Technical assistance is provided by Claphijo Enterprises.Interview with manufacturer

Replacement Components

Replacement is provided if need arises.Interview with manufacturer

Lifecycle

Lifetime is up to 10 years.Interview with manufacturer

Manufacturer Specified Performance Parameters

The oven is able to heat up to over 220°C.

The solar dryer can reduce the moisture content of a product from more than 60% to less than 10%.Interview with manufacturer

Depending on the sun, it takes two to three days for the food to dry.

Vetted Performance Status

None

Safety

Some low burn risk from handling hot trays.

Complementary Technical Systems

The solar drier comes with two pots.

Academic Research and References

Claphijo Enterprise partners with the University of Agriculture, Tanzania for its support in the testing and analysis of its solar drier.

Compliance with regulations

Unknown

Agriculture

August 21, 2024

Implemented by

SAECSA

Agriculture

August 22, 2024

Implemented by

SunWorks

Agriculture

August 22, 2024

Implemented by

UC Davis D-Lab

Agriculture

January 19, 2024

Agriculture

August 21, 2024

Implemented by

Alvan Blanch

Agriculture

August 21, 2024

Implemented by

Science for Society

Agriculture

August 21, 2024

Implemented by

Marius Rossouw design engineer Aflastop

Agriculture

January 22, 2024

Implemented by

Sparky Social Enterprise Ltd.

Agriculture

January 19, 2024

Implemented by

Solar Street Lights Africa

Agriculture

January 17, 2024

Implemented by

Centro de Desarrollo del Habitat y el Medio Ambiente (CEDES/Habitat)

Have thoughts on how we can improve?

Give Us Feedback