Agriculture

February 1, 2024

Iketsetse Single Stroke Maize Sheller

Read SolutionImplemented by

Elliot Litsebe Tsiame

Updated on August 21, 2024

·Created on August 18, 2018

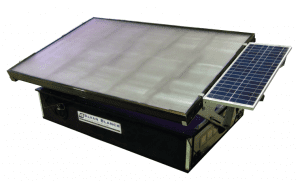

The EasyDry M500 is a portable drying device that is used to help achieve the proper moisture content for storage of maize.

The EasyDry M500 is an open-source portable maize dryer that has the capacity of drying up to 1500 kgs of maize per day. It is designed and locally manufactured by the AflaSTOP project which aims to incorporate it into the smallholder farmer’s normal post-harvest routine as a fee-based service.

The EasyDry M500 is designed for local fabrication. It has been manufactured at a cost of $850 USD in Kenya, $1,660 in Rwanda, and $1,100 in Tanzania and Uganda. This is inclusive of expected profit margins.

Target SDGs

SDG 2: Zero Hunger

SDG 1: No Poverty

Market Suggested Retail Price

$1,660.00

Target Users (Target Impact Group)

Small and Medium-sized Enterprises

Distributors / Implementing Organizations

The AflaSTOP project is implemented by ACDI/VOCA and Agribusiness Systems International, under the direction of Meridian Institute and in support of the Partnership for Aflatoxin Control in Africa (PACA). Distribution is done through retailing by the local artisan fabricators.

Competitive Landscape

Direct competitors include Solar Dryer - Model SD 22-3, SunWorks Solar Food Dryer, and GoSol Sol4 Oven.

Regions

East Africa

Countries

Kenya, Rwanda, Tanzania, Uganda

Manufacturing/Building Method

Production through skilled, local artisan fabricators.

Intellectural Property Type

Open-source

User Provision Model

Users can obtain the product through ACDI/VOCA.

In future the product will be available through local artisan fabricators.

Distributions to Date Status

Pilot phase still ongoing. Three EasyDry designs have been deployed in Kenya so far; two mechanical batch dryers and one solar option.

Drying capacity (lbs/m³)

1102.31

Drying duration (hr)

3

Load capacity (m³)

Unknown

Operating temperature range (°C)

Unknown

Temperature control

No

Number of trays

Materials of construction

Mild steel frame with a canvas bed

Design Specifications

Technical Support

Technical manuals provided online:

Replacement Components

Replacement components can be sourced from local artisans and hardware stores since it is made of locally available materials. Interview with representative.

Lifecycle

5 years

Manufacturer Specified Performance Parameters

Vetted Performance Status

Safety

The EasyDry M500 is a dangerous piece of agricultural equipment that consists of moving components and hot surfaces, posing possible injury risks. Extreme caution is required around the furnace area, the engine and v-belt assemblies. Children should be kept away from the aforementioned components at all times with bystanders minimized around these areas where possible. Children should be kept away at all times while the dryer is in operation. Do not use indoors unless well ventilated.

Complementary Technical Systems

AflaSTOP has come up with other projects geared towards combating aflatoxin in Kenya.

Academic Research and References

Compliance with regulations

AflaSTOP recommends that the manufacturing of the EasyDry should follow processes that are used and suitable for the country where it is deployed.

Other Information

Agriculture

February 1, 2024

Implemented by

Elliot Litsebe Tsiame

Agriculture

January 12, 2024

Implemented by

VIP

Agriculture

February 21, 2024

Implemented by

ABC Hansen Africa

Agriculture

August 21, 2024

Implemented by

Science for Society

Agriculture

January 22, 2024

Implemented by

Sparky Social Enterprise Ltd.

Agriculture

August 21, 2024

Implemented by

Claphijo Enterprises

Agriculture

August 21, 2024

Implemented by

SAECSA

Agriculture

August 21, 2024

Implemented by

Alvan Blanch

Agriculture

August 22, 2024

Implemented by

SunWorks

Agriculture

January 19, 2024

Have thoughts on how we can improve?

Give Us Feedback