Agriculture

January 12, 2024

Updated on August 8, 2024

·Created on October 1, 2018

The Nano Membrane Toilet is a dry-toilet that treats waste on-site without water or energy.

Cranfield Univeristy’s Nano Membrane Toilet treats waste without water or electricity, producing recycled water for household use along with energy and ash. The system uses the membrane to separate water from the waste and gasifies solids. The energy produced can be used to sustain the membrane process and any extra energy could be used to charge electronic devices.

This product is currently under development and is in the prototyping phase.

Target SDGs

SDG 6: Clean Water and Sanitation

Market Suggested Retail Price

$750.00

Target Users (Target Impact Group)

Household

Distributors / Implementing Organizations

Cranfield University plans to partner with local organizations is target regions to rent toilets to households.

Countries

Ghana, United Kingdom

Manufacturing/Building Method

The toilet structure is made entirely of composite material and can therefore be manufactured entirely using a 3-D printer and a laser cutter.

Intellectural Property Type

Trademark

User Provision Model

The proposed user provision model is for toilets to be rented by households.

Distributions to Date Status

No distributions to date; the product is still in its testing phase.

Toilet type

Toilet

Evacuation method

Dry

Storage conditions

Container Storage

Capacity (L)

Unknown

Time until emptying

Unknown

Design Specifications

The toilet rotates the solid and liquid waste mixture to empty it from the toilet, and then sedimentation separates solids from the mixture. Pathogens and odors are removed as water is transported through the membrane walls in the vapor state, and then recycled for household use. The partly-dry solids are then transported via mechanical screw to a gasifier, which converts the waste to ash and energy. The energy produced continues to power the membrane process, and extra energy can be used to charge devices.

Technical Support

Support is proposed to be provided every six months by a franchised maintenance company.

Replacement Components

The technicians would replace the membrane cartridge, bead cartridge, and the polymer.

Lifecycle

7 years (average)

Manufacturer Specified Performance Parameters

Designer specified performance targets include the daily operation cost being 0.05 USD/user/day, the energy recovered being 90 kW/user/day, and the water recovered being 1.5 L/user/day.

Vetted Performance Status

Field testing of a prototype was conducted in both a semi-public institutional setting and in peri-urban households in the Republic of South Africa. Additionally, laboratory experiments were conducted to determine that the best cleaning material for wiping the toilet bowl was a silicone rubber with oil-bleed-effect. The following study explains a new method for quantifying liquid fecal odors, which is an important aspect in promoting user acceptance of the Nano Membrane Toilet. The study also examines various membranes considered for use in the Nano Membrane Toilet. The following study highlights the potential of slow progressive burning and fuel blending to promote combustion of human feces - an important pre-treatment step for converting feces into energy. A performance assessment determined that a Sterling Engine within the toilet could potentially provide a net power output while simultaneously reducing harmful gas emissions.

Safety

In the unlikely event that the toilet breaks, the hydrophobic beads pose a potential choking hazard to children.

Complementary Technical Systems

Unknown

Academic Research and References

Hennigs, J. et al., 2019, Field testing of a prototype mechanical dry toilet flush, Science of The Total Environment, 668: 419–431.

López, E. P., 2014, Design and testing of a novel human-powered generator device as a backup solution to power Cranfield’s Nano-membrane Toilet, Master’s Thesis, Cranfield University.

Mercer, E. et al., 2018, Quantification of liquid phase faecal odourants to evaluate membrane technology for wastewater reuse from decentralised sanitation facilities, Environmental Science: Water Research & Technology, 5(1): 161–171.

Fidalgo, B. et al., 2019, Non-isothermal thermogravimetric kinetic analysis of the thermochemical conversion of human faeces, Renewable Energy 132: 1177-1184.

Parker, A., 2014, Membrane technology plays key role in waterless hygienic toilet, Membrane Technology 2014(12): 8.

Lieu Le, N., Nunes, S. P., 2016, Materials and membrane technologies for water and energy sustainability, Sustainable Materials and Technologies 7: 1-28.

Hanak, D. P. et al., 2016, Conceptual energy and water recovery system for self-sustained nano membrane toilet, Energy Conversion and Management 126: 352-361.

Kolios, A. et al., 2018, Probabilistic performance assessment of complex energy process systems – The case of a self-sustained sanitation system, Energy Conversion and Management 163: 74-85.

Cranfield University, Reinventing the toilet – helping to solve sanitation issues in low income countries. Available: https://www.cranfield.ac.uk/case-studies/research-case-studies/nano-membrane-toilet

Parker, A. et al., The Nano Membrane Toilet, Cranfield University.

Sustainable Sanitation Alliance, Nano Membrane toilet. Available: https://www.susana.org/en/knowledge-hub/projects/database/details/62

Wef Highlights, 2018, Nano Membrane Toilet is Flush with Funding. Available: https://news.wef.org/nano-membrane-toilet-is-flush-with-funding/

Pepitone, J., 2016, Waterless toilet turns waste into clean water and power. Available: https://money.cnn.com/2016/07/18/technology/waterless-toilet-nano-membrane/index.html

Bond, J-M., 2016, The waterless toilet, backed by Bill Gates, could change the world, Dailydot. Available: https://www.dailydot.com/debug/this-waterless-toilet-could-change-billions-of-lives/

New Atlas, 2016, Cheap, waterless toilet that turns waste into clean water and power to be trialed in Africa. Available: https://newatlas.com/waterless-nano-membrane-toilet/41108/

Compliance with regulations

Unknown

Evaluation methods

The manufacturer cites evaluation criteria based on the amount of energy they can produce in specific environments, the environmental impact they have, and how effective they are at killing pathogens

Other Information

Cranfield University produced a video to explain how their toilet works.

Winner of the CleanEquity Monaco 2015 award.

Agriculture

January 12, 2024

Agriculture

January 19, 2024

Implemented by

Clean Team Ghana

Agriculture

January 2, 2024

Implemented by

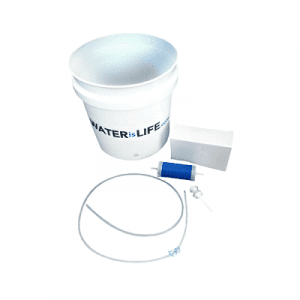

Water is Life

Agriculture

June 11, 2024

Implemented by

Ossian Agro Automation

Agriculture

December 19, 2023

Implemented by

Wostman

Agriculture

January 2, 2024

Implemented by

Toilets for People

Agriculture

December 20, 2023

Implemented by

Dry Flush

Agriculture

December 21, 2023

Agriculture

January 17, 2024

Implemented by

Easol Pvt Ldt

Agriculture

August 16, 2024

Implemented by

Ecoloo

Have thoughts on how we can improve?

Give Us Feedback