Agriculture

March 4, 2024

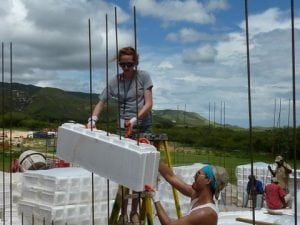

Lazarian Polystyrene Insulated Concrete Forms

Read SolutionImplemented by

Lazarian World Homes

Updated on March 7, 2024

·Created on May 26, 2016

NRG Insulated Block has embedded insulation in concrete masonry units.

NRG Insulated Blocks is a system of Continuously Insulated Concrete Masonry Units (CICMU’s) that combines the structural use of masonry with typical rigid insulation, locating the thermal break towards the outside of the block and maximizing internal thermal mass. The product is patent protected and is produced and sold in the United States.

Target SDGs

SDG 11: Sustainable Cities and Communities

SDG 12: Responsible Consumption and Production

Market Suggested Retail Price

$12.00

Target Users (Target Impact Group)

Household, Small and Medium-sized Enterprises

Distributors / Implementing Organizations

Manufacturers and distributors are located across several states in the US and are listed on the NRG website

Competitive Landscape

Direct competitors include Precast Concrete Beams and Slabs, Lazarian Polystyrene Insulated Concrete Forms, and Blockwalls Concrete.

Regions

North America

Manufacturing/Building Method

Made to order

Intellectural Property Type

Patent

User Provision Model

Users can obtain the product from the list of manufacturers/distributors

Distributions to Date Status

"Tens of thousands of units" have been fabricated and distributed throughout North America since 2010.Interview with representative

Unit dimensions (cm)

Available sizes vary from producer to producer

Primary materials

Concrete

Complimentary materials

Expanded polystyrene

Fire Resistance (hr)

2 hr

Thermal Insulation Capacity

R-22

Compressive Strength (MPa)

41.5 MPa

Suitable Climates

Suitable in all climates, though currently only available in North America

Design Specifications

The blocks are available in standard 8", 10" and 12" depths, and full and half heights. The product comes in brick and concrete finishes.

Technical Support

For questions regarding NRG insulated block installation, you can contact them through their website or reach out to individual manufacturers/distributors.

Replacement Components

It is unlikely that repairs are needed (see Lifecycle section), however further blocks can be ordered from manufacturers/distributors should sections of a structure need to be rebuilt.

Lifecycle

NRG blocks are designed for permanent construction projects

Manufacturer Specified Performance Parameters

Construction Cost Savings and Operational Cost Savings are performance targets specified by the manufacturer.

Vetted Performance Status

NRG Insulated Blocks have undergone structural performance tests and a thermodynamics assessment.

Safety

Any installation of NRG Blocks should conform with local building codes and construction safety requirements.

Complementary Technical Systems

Termobuild floor system is recommended by NRG as a complementary product.

Academic Research and References

“Architects-Engineers”, NRG Insulated Blocks, accessed on March 7, 2024, https://nrgblock.com/arch-eng/

Compliance with regulations

ASHRAE - American Society of Heating, Refrigerating, and Air-Conditioning Engineers

ASTM - American Society for Testing and Materials

Evaluation methods

Testing organizations have conducted standard compression and lateral load tests. Economic advantages, studied primarily by the manufacturer, makes comparisons to standard recognized wall assemblies while taking associated heating and cooling costs into account.

Other Information

NRG Insulated Block patent

Complimentary technical system Termobuild

“Masons/Producers”, NRG Insulated Blocks, accessed on March 7, 2024, https://nrgblock.com/masons/

Agriculture

March 4, 2024

Implemented by

Lazarian World Homes

Agriculture

March 4, 2024

Implemented by

Makiga Engineering Services LTD

Agriculture

March 13, 2024

Implemented by

Watershed Materials

Agriculture

February 26, 2024

Implemented by

Advanced Earthen Construction Technologies (AECT)

Agriculture

February 27, 2024

Implemented by

California Institute of Earth Architecture (CalEarth)

Agriculture

March 8, 2024

Implemented by

ByFusion

Agriculture

February 26, 2024

Implemented by

Grupo Ecoplasso

Agriculture

March 1, 2024

Agriculture

August 16, 2024

Implemented by

Green Pavers

Agriculture

March 14, 2024

Implemented by

Straw Resource Ltd.

Have thoughts on how we can improve?

Give Us Feedback

This product states that repair parts will be available to the customer but that on-site support will be provided to the customer by the manufacturer. This is not practical for an installed base of more than ~50 units. The global distribution to both Africa and India will require 24 x 7 staffing and when repair is required the unit will either need to be returned for repair or repaired on site. If the product is simple enough that the user can repair most issues than service instructions will be required. Sending out someone from the factory to support each product is not practical.