Agriculture

February 29, 2024

Updated on March 8, 2024

·Created on August 16, 2016

RePlast blocks are made from recycled plastics that are heated and compressed using ByFusion systems.

Replast blocks are entirely made of recycled plastic without additives and fillers. They are designed to be a complementary integration to traditional building materials such as lumber, steel, and cement.

Target SDGs

SDG 11: Sustainable Cities and Communities

SDG 12: Responsible Consumption and Production

Market Suggested Retail Price

$1.95

Target Users (Target Impact Group)

Household

Distributors / Implementing Organizations

ByFusion

Competitive Landscape

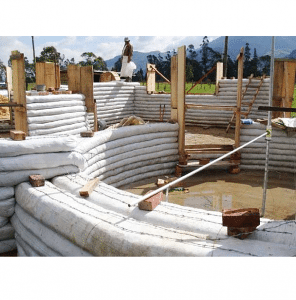

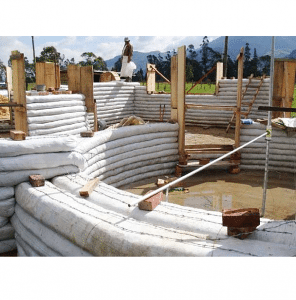

Direct competitors include Bloqueplas, Bottle Bricks, and Earthen Bag.

Regions

Worldwide

Manufacturing/Building Method

ByFusion has developed a machine that produces the RePlast blocks from plastic waste. The machine and the blocks are still in a proof of concept phase. The blocks can be used in infrastructure work or as wall fill.

Intellectural Property Type

Trademark

User Provision Model

The ByFusion machine is self contained and can fit into one shipping container so it can be brought where the plastic is located.

Distributions to Date Status

One building on Kauai made out plastic marine debris and plastic household waste

Unit dimensions (cm)

40.0 x 19.8 x 22.7 cm3

Primary materials

Plastic

Complimentary materials

None

Fire Resistance (hr)

Unknown

Thermal Insulation Capacity

K-Factor: 0.86

Compressive Strength (MPa)

2.81 MPa

Suitable Climates

All climates

Design Specifications

RePlast blocks are created through the following process:

The construction of a RePlast wall includes:

7 types of plastic can be used to make the blocks. They are:

Fusion Machine specifications (for 500 blocks per day):

Technical Support

The machine requires minimal staff and training to operate.

Replacement Components

The machine itself is made with standard industry parts that can be replaced in most parts of the world.

Lifecycle

+100 years

Manufacturer Specified Performance Parameters

No glues or adhesives, no crack or crumble, zero-waste process, no specialized labor required.

Vetted Performance Status

ByFusion claims that the product has undergone initial independent testing for compression, R-value, and shear strength, but no results are provided. RePlast has been used over the past few years in retaining wall projects and has withstood severe climatic conditions including earthquakes and has not shown signs of failure.

Safety

Workers may be exposed to regular dangers of a construction site that include working at heights and with sharp tools and materials. Standard safety procedures must also be followed in the operation of the ByFusion machine.

Although ByFusion intends to conduct testing for fire resistance, they recommend applying a mortar finish to protect from UV damage and to create a thermal heat barrier.

Complementary Technical Systems

None

Academic Research and References

“Data Sheet”, ByFusion, accessed on March 8, 2024, https://www.byfusion.com/byblock#data-sheet-overlay

Compliance with regulations

Unknown

Evaluation methods

ASTM C165-07, ASTM D1761-12, ASTM C518-017, ASTM E90-09, ASTM E831-19

Other Information

“ByBlock”, ByFusion, accessed on March 8, 2024, https://www.byfusion.com/byblock/

“Building for the Future”, ByFusion, accessed on March 8, 2024, https://www.byfusion.com/building-for-the-future/

“FAQ”, ByFusion, accessed on March 8, 2024, https://www.byfusion.com/faq-byblock/

Agriculture

February 29, 2024

Agriculture

February 29, 2024

Implemented by

Hydraform

Agriculture

March 7, 2024

Implemented by

Francis Kennedy

Agriculture

February 26, 2024

Implemented by

Grupo Ecoplasso

Agriculture

March 1, 2024

Agriculture

March 6, 2024

Agriculture

June 30, 2024

Implemented by

Lifeway Solar

Agriculture

June 23, 2024

Implemented by

Carpolo (Mohammad Nabaa & Ralph Khairallah)

Agriculture

March 13, 2024

Implemented by

Mycotech Lab (MYCL)

Agriculture

March 14, 2024

Implemented by

Straw Resource Ltd.

Have thoughts on how we can improve?

Give Us Feedback

Accessibility of the machine is a key issue that perhaps needs to be addressed. Accessibility in terms of shipping/distribution to various locations (remote areas?), accessibility to distributors/dealers, as well as accessibility in terms of cost.

If this machine costs US$50,000, then the business model is such that only licensed proprietors who seek to establish a business producing these are the market.

Until then, determining an average cost per block on the market is relative and unknown.

I would also continue to include “the manufacturer claims….” for all other performance criteria, since very little performance data has been provided.

Market Suggested Price: Will costs be determined per block or per machine? The end-user will be purchasing blocks for $X, but the cost of the machine is actually $100,000. The cost of the machine, and the set-up service costs, are all factors in determining the market. A machine purchase may be accessible for municipalities or entrepreneurs who serve as distributors, but perhaps a machine rental by a single project manager or procurement person on a single community-building project may be limited until a distribution chain is developed.

It’s a good idea, but I’m not seeing indications that it will be accessible, particularly for underserved communities, anytime soon.

Intellectual Property: If this category is to be included, it will need to also indicate which specific aspects are protected, the country of protection, and whether or not the patent has been granted or is in process. All (and others) are factors in intellectual property rights, and it may be misleading for viewers to simply say it is patented and closed to replication/distribution.

There may be just one part or component that is patented, so if Intellectual property category is included in this solutions library, it then opens up other necessary qualifying clarifications.

In general, by protecting this innovation, the manufacturer is choosing to control the distribution, which makes one question the intent of saving a global issue, or capitalizing (and limiting) its reach.

Competitive Landscape: Hydraform Earth block machine.

Waste to Value blocks? Or alternative blocks?

Could Strawbales, other CEBs and adobe also be competitors?

Target User: This needs clarification if ‘user’ will be the actual person who buys blocks, or the block machine purchaser. For the person who buys blocks, unless a business/supply chain model is explained, I’m not sure how the average home-builder would obtain these blocks. If a machine purchaser, the target user might be large scale entities who can afford the machine- such as municipalities or entrepreneurs who will then rent or lease out the machine locally.

It would be important to note what is verified claims and what are manufacturer’s claims.

Fuel needs to be a consideration, and may be a limiting factor in under-resourced communities.

Transporting the machine to site locations with limited road-networks and poor conditions may prove to be a limitation.