Agriculture

March 4, 2024

Makiga Stabilized Soil Block Press

Read SolutionImplemented by

Makiga Engineering Services LTD

Updated on March 1, 2024

·Created on December 3, 2018

Interlocking Stabilized Soil Blocks (ISSB) are bricks that are made from compressed mixed soil using an ISSB machine.

Interlocking Stabilized Soil Blocks, also called Interlocking Compressed Earth Blocks (ICEBs), are bricks that are made from mixed soil that can be found on or off the construction site. The soil is usually mixed with cement, water, and other additives to improve its characteristics. The soil is compressed using an ISSB machine and the blocks are laid with mortar in a staggered pattern similar to other types of masonry.

Target SDGs

SDG 11: Sustainable Cities and Communities

SDG 12: Responsible Consumption and Production

Market Suggested Retail Price

$10.00

Market Suggested Retail Price (Secondary Currency)

35,000

Target Users (Target Impact Group)

Household, Community, Small and Medium-sized Enterprises, Public Sector Agencies, NGOs

Distributors / Implementing Organizations

Most implementation has been in Africa by organizations including Makiga, Technology for Tomorrow, Haileybury Youth Trust (HYT), and Connect Africa, among others.

Competitive Landscape

Direct competitors include Watershed Block, Makiga Stabilized Soil Block Press, NRG Insulated Block, and Blockwalls Concrete.

Regions

Africa, Asia, Australia-New Zealand Region, Central America, Latin America, North America, South Asia

Manufacturing/Building Method

Either can be mass produced, made to order, or made directly on the site with soil found on the site

Intellectural Property Type

Open-source

User Provision Model

Users can obtain the blocks from an implementing organization, manufacturer, or distributer, or with the correct training and equipment can produce the blocks themselves.

Distributions to Date Status

Unknown

Unit dimensions (cm)

Varies

Primary materials

Clay-retaining earth

Complimentary materials

N/A

Fire Resistance (hr)

Unknown

Thermal Insulation Capacity

0.354 W/m²K

Compressive Strength (MPa)

2.5 – 6.7 MPa

Suitable Climates

Not suitable for cold climates unless necessary vapor barriers and insulation can be added. On their own ISSBs and CEBs do not hold up well to freeze/thaw cycles and have a low thermal insulation capacity.

Design Specifications

Arup produced a report for compressed earth blocks in general that includes information for soil preparation, stabilizers, block dimensions, compression or extrusion, curing, block property testing, construction, finishing, and design parameters such as wall thickness, percentage of windows in a wall, and considerations when building in non-seismic and seismic areas.

UN Habitat in collaboration with Good Earth Trust (GET) has a report specifically for ISSBs and presents similar information in a series of simple diagrams.

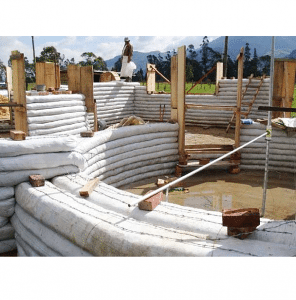

Most ISSBs in East Africa are made with an ISSB machine that compresses the soil into the interlocking form. Depending on the machine, the following blocks can be produced: Straight Double Interlocking Block, Curved Double Interlocking Block, Wide Format Interlocking Block, Straight Single Interlocking Block, or Grooved Double Interlocking Block.

Planning the production of ISSBs starts with the site and properties of the soil there. A sedimentation test can be performed to determine the percentages of clay, silt, sand, and gravel in the soil. Other tests include shrinkage tests, sending the soil to the laboratory, or using a portable soil-testing kit.

Stabilizers include cement lime or bitumen, fibrous natural materials, chemicals and resins, or sands and gravels. It is important to refer to more detailed material to determine what stabilizer is most appropriate for the type of earth mix that is being used.

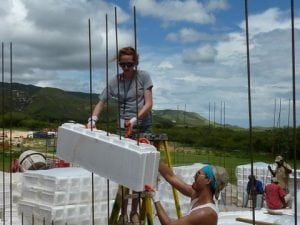

The process of producing the blocks includes steps of training the labour force (quality assurance is extremely important for ISSB production), excavation, sieving, mix preparation, mixing, measuring the mix, compressing the mix, removing the block, dry and stack, and quality check.

Technical Support

Technical support can be found from the manufacturer or distributer, or from the reports listed in the Design specifications section. Another resource is the Auroville Earth Institute, and on their links page they list their full network of earth-building specialists including CRAterre, Cartoterra, Dachverband Lehmbau (the German association for building with earth), Earth Block International, and Rural Housing Knowledge Network, among others.

Replacement Components

It is unlikely that repairs are needed (see Lifecycle section), however new blocks can be produced should sections of a structure need to be rebuilt.

Lifecycle

Though the full lifespan is unknown, historical precedent and testing signify that if built to a high level of quality and with the most appropriate soil mix and detailing, ISSBs and ICEBs can last decades similar to the lifespan of fired earth bricks.

Manufacturer Specified Performance Parameters

Performance targets include affordability, sustainability, ease of use, good performance, and versatility. A key factor for ISSB is that care must be taken to ensure quality.

Vetted Performance Status

Academic institutions have performed numerous calculations and tests to analyse strength properties, thermal conductivity, and introduction of bacteria or alternative stabilizers among many more. It is not necessarily the case that these tests inform construction.

Safety

Workers are subject to the general dangers of a construction site including working from heights and with sharp tools. ISSBs do not require operation of any large machinery.

Complementary Technical Systems

Curved ISSB's are being used to make granaries, water tanks, lining for pit latrines, and septic tanks. The ISSB machine used to compress the blocks is a complimentary product available from Makiga, and Hydraform among others.

Academic Research and References

Allen GTR. 2012. Strength Properties of Stabilized Compressed Earth Blocks with Varying Soil Compositions. University of Colorado at Boulder, ProQuest Dissertations Publishing.

Leitão D. 2017. Thermal performance assessment of masonry made of ICEB’s stabilised with alkali-activated fly ash. Energy and buildings. 139: 44-52.

Irwan JM, Zamer MM, and Othman N. 2016. A Review on Interlocking Compressed Earth Blocks (ICEB) with Addition of Bacteria. MATEC Web of Conferences. 47.

Villamizar MC, Araque VS, Ríos Reyes CA, Silva RS. 2012. Effect of the addition of coal-ash and cassava peels on the engineering properties of compressed earth blocks. Construction and Building Materials. 36: 276-286.

Heath, A et al. 2009. Compressive strength of extruded unfired clay masonry units. Proceedings of the ICE — Construction Materials, 162(3): 105-112.

Heath A, Maskell D, Walker P, Lawrence M, and Fourie C. 2012. Modern earth masonry, structural properties and structural design. The Structural Engineer, 90(4): 38-44.

Huber H and Guillaud H. 1994. Earth construction: a comprehensive guide. ITDG.

Minke, G. 2002. Construction manual for earthquake-resistant houses built of earth. Eschborn.

Morton, T. 2008. Earth masonry, design and construction guidelines. BRE Press.

Oti J, Kinuthia, JM, and Bai J. 2009. Unfired clay bricks: from laboratory to industrial production. Proceedings of the ICE — Engineering Sustainability 162(4): 229-237.

Smith, E. 2010. Interlocking stabilised soil blocks: appropriate technology that doesn’t cost the earth. The Structural Engineer, 88(15/16): 25-29.

Walker P. 2002. HB195-2002. The Australian earth building handbook. Standards Australia.

UN-Habitat, 2009, Interlocking Stabilised Soil Blocks , Appropriate earth technologies in Uganda

Compliance with regulations

Specifications for unfired earth blocks exist in Australia, El Salvador, France, Belgium, Germany, India, Kenya, New Zealand, Uganda, and USA. Broader earth specifications are also available in Peru and the Ivory Coast. A table with the specific names and page counts of these design codes are included in the Arup report.

Other Information

Makiga has a project gallery of structures made with ISSB.

Additional resources can be found in the Auroville Earth Institute, and on their links page they list their full network of earth-building specialists including CRAterre, , Dachverband Lehmbau (the German association for building with earth) and Earth Block International, among others.

“Climate friendly construction”, HYT Uganda, accessed on March 1, 2024, https://hytuganda.com/climate-friendly-construction/

“ISSB”, T4T Africa, accessed on March 1, 2024, https://t4tafrica.co/equipments/issb/

“Wide Interlocking Soil Block Press Machine”, Makiga Engineering Services LTD, accessed on March 1, 2024, https://makiga-engineering.com/products/wide-interlocking-soil-block-press-machine/

Agriculture

March 4, 2024

Implemented by

Makiga Engineering Services LTD

Agriculture

August 20, 2024

Implemented by

Technology for Tomorrow (T4T) Africa

Agriculture

February 6, 2024

Implemented by

Australian Centre for International Agricultural Research

Agriculture

February 7, 2024

Implemented by

SoilSense

Agriculture

February 29, 2024

Implemented by

EarthEnable

Agriculture

February 29, 2024

Implemented by

EarthTek Inc.

Agriculture

February 29, 2024

Agriculture

February 29, 2024

Implemented by

Hydraform

Agriculture

March 4, 2024

Implemented by

Lazarian World Homes

Agriculture

March 13, 2024

Implemented by

Angirus Ind Pvt. Ltd.

Have thoughts on how we can improve?

Give Us Feedback

I am interested in interlocking solid blocks for making walls of houses. There are several machines that seem to be available for this purpose, especially the Makiga Block Presses which I believe are manufactured in Kenya.

My home is in Canada and we certainly have cold winters here. I have read on this site that stabilized soil blocks that are made with a large percentage of soil and a much smaller percentage of cement … would not tolerate the cold weather here in my country. Because of this, I am wondering if a person made similar, solid, interlocking blocks like those produced on most of the Makiga machines … if they could be made to tolerate this freezing weather by substituting the materials that make up the ingredients. Instead of using such materials as clay, soil, etc. perhaps they could be manufactured but only employing ingredients like cement, sand, gravel, small rocks, etc.

Of course, the resulting blocks would definitely cost more to make – compared to stabilized soil blocks.

Makiga does make one machine for blocks which they call their “Makiga Block Master”. It is manually operated and requires no electricity. This machine produced high-strength Makiga Concrete Blocks. The materials used to make these particular blocks include cement, sand, 1/4″ ballast, and/or quarry dust.

I guess what I am wondering here is if there is a manually – operated, small machine that produces interlocking concrete blocks that would be suitable for a cold climate, and also be strong enough to be used in the construction of walls for homes etc. ( no holes of any kind in such concrete blocks)

Thank you are any input you might care to provide. – David Whalen in Canada. whalendave325@gmail.com