Agriculture

February 29, 2024

Updated on February 26, 2024

·Created on August 16, 2016

Interlocking block system made of recycled plastic and rubber.

Bloqueplas is an interlocking wall system of stackable tongue and groove block units manufactured and distributed by Grupo Ecoplasso in Colombia. The blocks are made of recycled polyethylene terephthalate (PET), and require only a hammer to assemble a structure.

Target SDGs

SDG 11: Sustainable Cities and Communities

SDG 12: Responsible Consumption and Production

Market Suggested Retail Price

$4.60

Market Suggested Retail Price (Secondary Currency)

21,610.85

Target Users (Target Impact Group)

Household, NGOs

Distributors / Implementing Organizations

Grupo Ecoplasso in Colombia and Mexico Audeo in Phillipines

Competitive Landscape

Direct competitors include RePlast and Bottle Bricks.

Countries

Argentina, Colombia, Costa Rica, Dominican Republic, Ecuador, Guatemala, Mexico, Philippines, Spain

Manufacturing/Building Method

Bloqueplas is mass produced in Colombia by heating and melting PET pellets from recycled containers. The component is fabricated using thermoplastic extrusion where the material is extruded continuously through a die opening and retained in molds to obtain the final form of the block.

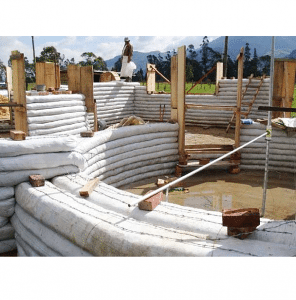

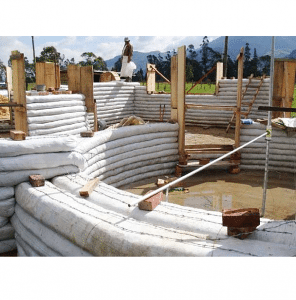

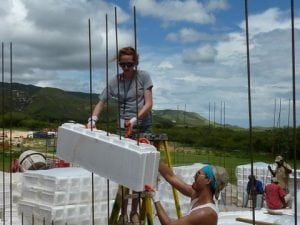

The construction method of the Bloqueplas system consist on laying and interlocking the blocks to form walls following a preset layout. The walls have reinforcement of columns and beams produced with same method. Complementary reinforcement include steel or aluminum profiles connected with conventional fasteners.

Intellectural Property Type

Patent

User Provision Model

Users can obtain product from Conceptos Plásticos and Bloqueplass.

Distributions to Date Status

Conceptos Plasticos outlines that the blocks have been used to construct more than 59 houses

Unit dimensions (cm)

53 cm x 13 cm x 7 cm

Primary materials

Recycled polyethylene terephthalate (PET)

Complimentary materials

None

Fire Resistance (hr)

The manufacturer declares the product is fireproof

Thermal Insulation Capacity

Manufacturer informs that the material and chemical composition of the blocks become insulators of cold and heat, keeping the interior of the building at a constant average temperature. Its strong grip creates a natural barrier against noise, water, and wind.

Compressive Strength (MPa)

200 MPa

Suitable Climates

Could be suitable for any climate if extra measures taken to accommodate insulation for colder climates.

Design Specifications

The Bloqueplás construction system consists of structural and non-structural elements including blocks, columns, lintels, and beams. The components are made from all types of recycled plastics that are mainly comprised of polyethylene and polypropylene. The plastics are sorted and melted and then the mixture is extruded through a form. The block is compact and fused in one piece and forms the building system by joining with other elements such as beams and columns. The elements are designed to be friction fit so they can be easily assembled and do not require any mortar like is required for standard brick modules.

Technical Support

None

Replacement Components

All the components can be replaced by purchasing new pieces from the manufacturer.

Lifecycle

The manufacturer claims that plastics take over 500 years to biodegrade and therefore the homes could last for many generations.

Manufacturer Specified Performance Parameters

High insulating value, durability (protecting from noise, water, wind, insects, and pathogens), earthquake resistance, and quick construction.

Vetted Performance Status

A study performed by Universidad Santo Tomas in Bogota, Colombia, reported the system is a feasible alternative to contribute to increasing the recycling rate of waste plastic and decreasing the housing deficit in Colombia. From the material perspective, the study cites the following features as advantages of the system: lightweight, modular, the wall made of blocks does not require plastering, beneficial thermal, acoustic, and earthquake proofing properties. Although the components strength is lower than conventional ceramic blocks, the resistance is acceptable for housing construction, according to the study.

Safety

Builders should wear appropriate protective equipment such as hardhats, gloves and safety glasses while working to protect against physical injury commonly associated with heavy construction.

Complementary Technical Systems

Electricity, sanitation, and water infrastructure are required.

Academic Research and References

Llanos, F., Bodensiek, T., 2017, Bloqueplas: Construction System with Blocks made from Recovered Plastic, 3rd International and 5th National Congress of Sustainable Construction and Eco-Efficient Solutions.

“Patents”, Grupo Ecoplasso, accessed on February 26, 2024, https://bloqueplas.com/index.php/grupo-ecoplasso/reconocimientos

“Bloqueplas”, Grupo Ecoplasso, accessed on February 26, 2024, https://bloqueplas.com/index.php/brickarp

“Bricks and Blocks”, Conceptos Plasticos, accessed on February 26, 2024, https://conceptosplasticos.com/content/brick-and-blocks.html

“Proyects”, FICIDET, accessed on February 26, 2024, https://ficidet.org/proyectos

Castillo, Diana, 2018. Análisis de la implementación de ladrillos fabricados a partir de plástico reciclado como material de construcción, Universidad Santo Tomás Facultad Ingeniería Civil, Bogotá.

Compliance with regulations

Unknown

Evaluation methods

Unknown

Other Information

"Albergue para la protección en Guapi", Conceptos Plásticos, accessed on February 26, 2024. Video of a building construction process in Colombia developed by Conceptos Plasticos.

Bloqueplas building system participated in Rethink Plastics Challenge

“Videos”, Grupo Ecoplasso, accessed on February 26, 2024, https://bloqueplas.com/index.php/medios/videos

Agriculture

February 29, 2024

Agriculture

February 29, 2024

Implemented by

Hydraform

Agriculture

March 7, 2024

Implemented by

Francis Kennedy

Agriculture

March 4, 2024

Implemented by

Lazarian World Homes

Agriculture

March 1, 2024

Agriculture

March 6, 2024

Agriculture

June 30, 2024

Implemented by

Lifeway Solar

Agriculture

June 23, 2024

Implemented by

Carpolo (Mohammad Nabaa & Ralph Khairallah)

Agriculture

March 13, 2024

Implemented by

Mycotech Lab (MYCL)

Agriculture

March 14, 2024

Implemented by

Straw Resource Ltd.

Have thoughts on how we can improve?

Give Us Feedback