Agriculture

August 4, 2024

Bandha Bikes

Read SolutionImplemented by

Hatch International

Updated on March 14, 2024

·Created on October 27, 2022

Timbercrete is an environmentally sustainable masonry building product that combines the structural qualities of masonry with the resilient qualities of timber.

Timbercrete, designed and manufactured by Timbercrete, an Australian firm, is a hybrid blend of natural organic material (a blend of waste timber or cellulose) combined with masonry binders (cement and sand), that produce a larger, more flexible, high insulation and lighter alternative construction material. This product was designed by Peter Collier, a professional potter and ceramic technician who was looking for a way to build an affordable family home. He started experimenting with raw materials, using his experience with clay and eventually came across the blend of cellulose, cement, sand and binders that has been patented as Timbercrete today. Timbercrete is produced in a range of products of bricks, panels, pavers and blocks.

Target SDGs

SDG 11: Sustainable Cities and Communities

SDG 9: Industry, Innovation and Infrastructure

Market Suggested Retail Price

$9.10

Target Users (Target Impact Group)

Household, Community, Small and Medium-sized Enterprises

Distributors / Implementing Organizations

Timbercrete is distributed by the manufacturer.

Agriculture

August 4, 2024

Implemented by

Hatch International

Agriculture

June 23, 2024

Implemented by

Code for America

Agriculture

June 23, 2024

Implemented by

Kiira Motors Corporation

Agriculture

June 18, 2024

Implemented by

SES S.A.

Agriculture

June 22, 2024

Implemented by

OX Global Ltd

Agriculture

June 4, 2024

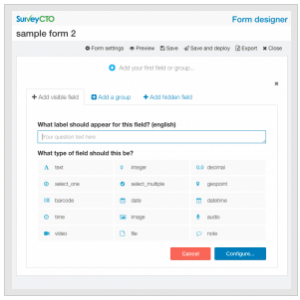

Implemented by

Dobility Inc

Agriculture

May 24, 2024

Implemented by

Arinifu (George Chege)

Agriculture

March 7, 2024

Implemented by

International Network for Bamboo and Rattan (INBAR)

Agriculture

June 26, 2024

Implemented by

University of Philippines

Agriculture

June 1, 2024

Implemented by

Socialcops

Have thoughts on how we can improve?

Give Us Feedback