Agriculture

December 3, 2024

Envirofit M-5000

Read SolutionImplemented by

Envirofit International

Updated on February 23, 2024

·Created on August 27, 2015

A compressed earth block machine maker.

The Adopress 5000 is a patented compressed earth block machine produced by EcoBlock International. The Adopress is designed to use local materials available in Mexican communities to manufacture the ‘Adoblocks’ and build stabilized adobe housing. The machines are provided to communities via programs from the social franchise programme – Echale a tu Casa – with a payment method aimed to help low income families pay for the product over time. Target users are Families who do not have access to housing, medical, or any government assistance and earn between 1 to 4 times the minimum wage salary (150 USD to 597 USD) per month.

Target SDGs

SDG 11: Sustainable Cities and Communities

SDG 1: No Poverty

Target Users (Target Impact Group)

Household, Community, NGOs

Distributors / Implementing Organizations

Echale a tu Casa, a social franchise program developed by EcoBlock International

Competitive Landscape

Direct competitors include Hydraform M9, AECT Impact 2001A Compressed Earth Block Machine, and Terrabric 2B.

Regions

Latin America

Countries

Mexico

Manufacturing/Building Method

Ital Mexicana S.A. can mass produce the Adopress 5000 at its manufacturing plant in Mexico City. However, the Adoblock itself is produced individually, using the Adopress 5000, that can be operated by community members as they construct the structures.

Intellectural Property Type

Trade Secret

User Provision Model

Echale a tu Casa will identify communities in need and establish a presence, discover a need, and implement a solution. Echale a tu Casa uses government subsidies and a carefully designed social franchising system to sell the product to communities. Allbiz also offers the Adopress 3000 online.

Distributions to Date Status

30,000 new homes constructed, 150,000 home improvements made since the company's inception in 1985. No information on number of Adopress products distributed is available at this time.

System Dimensions

Unknown

Portability (yes/no)

No

Raw materials used

Earth, clay, sand, and cement

Recommended water content (ratio)

10%

Induced pressure (Mpa)

4.13 – 10.3 Mpa

Power source

Electric or diesel, three phase motor (10 HP)

Finished unit dimensions

Block dimensions of 10 x 20 x 40 cm or 10 x 15 x 30 cm

Rate of production (units/hour)

1,500 – 2,200 units/hour

Curation duration (days)

Unknown

Suitable climate

Not suitable for cold climates unless necessary vapor barriers and insulation can be added. On their own ISSBs and CEBs do not hold up well to freeze/thaw cycles and have a low thermal insulation capacity.

Design Specifications

The Adopress 5000 produces Adoblocks which are made with soil, cement, cal and/or sand. The blocks are comprised of more than 90% local soil and serve as a natural insulation source and reduces reliance on heating and cooling devices.

The machine requires an electric, three phase motor or diesel 10 HP engine. Operation with 3 personnel can achieve daily production (i.e. 8 hour shift) of 1,500 (10 x 20 x 40 cm) or 2,200 (10 x 15 x 30 cm) Adoblocks.

Additional dimensions and weight not specified.

Technical Support

Families are trained by EcoBlock International technicians about the operation of Adopress. Echale offers technical assistance from start to finish to self-organized communities in order to promote sustainability after Echale leaves the community.

Replacement Components

Unknown. The bricks are made from locally available materials.

Lifecycle

Unknown

Vetted Performance Status

According to the manufacturer, Adoblocks are 30-40% more resistant than traditional fired bricks or concrete blocks. Adoblocks also act as an insulation material due to the acoustic properties of the main raw material used: earth.

Safety

Unknown

Complementary Technical Systems

Ecoblock International's program, Echale a tu Casa, works best when properly implemented with its social financing and community building method to ensure the longevity and sustainability of the Adopress 5000.

Academic Research and References

“Ecoblock”, Echale, accessed on February 23, 2024, https://echale.mx/ecoblock/

“Adoberas”, Ital Mexicana S.A., accessed on February 23, 2024, https://www.ital.com.mx/#equipos

“Calakmul Rural Housing Programme”, World Habitat, accessed on February 23, 2024, https://world-habitat.org/world-habitat-awards/winners-and-finalists/calakmul-rural-housing-programme/

Graham, C., et al., 2005, Movement Coefficients of Compressed Earth Masonry Units. 10th Canadian Masonry Symposium. (Not peer reviewed)

Morony, J., 2004, Logged Data For Heat Wave, Preliminary report. (Not peer reviewed)

Graham, C., et al., 2001, Soil Block Home Construction. BTEC Sustainable Buildings III Conference. (Not peer reviewed)

“Ecoblock International”, Kiva, accessed on February 23, 2024, https://www.kiva.org/about/where-kiva-works/partners/301

“Sustainability Report”, Echale a tu Casa, accessed on February 23, 2024, https://resiliencesystem.org/sites/default/files/GRI_English-2.pdf

Compliance with regulations

Unknown

Other Information

Echale requires a minimum of 30 families to express interest in order to take part in the project. Echale's approach involves setting up a local housing committee that holds regular meetings to develop a housing program, interact with other stake holders and replicate a social franchise. By creating this committee, Echale hopes to promote the sustainability of the product and community.

Echale works with the National Housing Commission (CONAVI), the Federal Mortgage Trust (SHF), the Houseing Institue of Campeche (INVICAM), and a local NGO Impulsac, however no awards/certifications are listed from these entities.

Highest score amongst B Corp honorees for Best for the World 2013. Echale is a GIIRS pioneer, a B-Lab corporation, a Schwab Foundation, entrepreneur, and an Ashoka Fellow.

“Brick Manufacturing Equipment”, Allbiz, accessed on February 23, 2024, https://mx.all.biz/en/brick-manufacturing-equipment-g4715#.V7Ho85grI2w

Agriculture

December 3, 2024

Implemented by

Envirofit International

Agriculture

February 26, 2024

Implemented by

Advanced Earthen Construction Technologies (AECT)

Agriculture

June 22, 2024

Implemented by

Bridges to Prosperity

Agriculture

February 28, 2024

Agriculture

June 5, 2024

Implemented by

Stamen Design

Agriculture

March 1, 2024

Implemented by

George Nez and Albert Knott

Agriculture

February 23, 2024

Implemented by

All Hands Volunteers (All Hands and Hearts)

Agriculture

February 23, 2024

Implemented by

Bridges to Prosperity

Agriculture

February 23, 2024

Implemented by

Habitat for Humanity

Agriculture

May 24, 2024

Implemented by

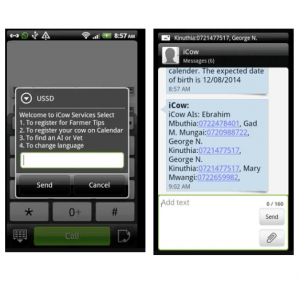

iCow

Have thoughts on how we can improve?

Give Us Feedback