Agriculture

February 26, 2024

Updated on February 29, 2024

·Created on August 27, 2015

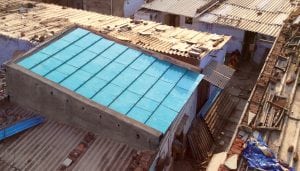

Hydraform is an interlocking block making machine.

Hydraform M9 Interlocking Block Making Machine produces up to 500 blocks per 8-hour shift.

Target SDGs

SDG 11: Sustainable Cities and Communities

SDG 12: Responsible Consumption and Production

Market Suggested Retail Price

$14,810.00

Target Users (Target Impact Group)

Community, Small and Medium-sized Enterprises, Public Sector Agencies, NGOs

Distributors / Implementing Organizations

Hydraform and nonprofits in social sector applications.

Competitive Landscape

Direct competitors include Adopress 5000, AECT Impact 2001A Compressed Earth Block Machine, and Terrabric 2B.

Regions

Worldwide

Manufacturing/Building Method

Pricing, exporting and terms of training and guarantees are outline here. For a quote, email: sales@hydraform.com

Intellectural Property Type

Patent

User Provision Model

Hydraform must be contacted for an individual quote.

Email: sales@hydraform.com

Phone: +27 11 913 1449 (South Africa)

Distributors are also located in Angola, DRC, Nigeria, Tanzania, and Tunisia, with it's East African office located in Uganda.

Distributions to Date Status

Over 4000

System Dimensions

Unknown

Portability (yes/no)

Yes

Raw materials used

Earth, sand, clay, and cement

Recommended water content (ratio)

Unknown

Induced pressure (Mpa)

Unknown

Power source

220 V electric motor

Finished unit dimensions

22 x 11.5 x 23 cm3

Rate of production (units/hour)

63 units/hour

Curation duration (days)

Unknown

Suitable climate

Not suitable for cold climates unless necessary vapour barriers and insulation can be added. On their own ISSBs and CEBs do not hold up well to freeze/thaw cycles and have a low thermal insulation capacity.

Design Specifications

The M7 E380 is stationary and ideal for small size projects especially where 3-phase power is easily available. It is capable of producing around 1500 blocks per day (equivalent 40-50m² of wall). Mixing can be done by hand especially if labour cost is low and community involvement is key to the project. Design specifications follow:

Finished brick size (LxWxH) (cm): 22 x 22 x 14

380V, 7.5 kW electric motor

Requires 7 to 9 staff for operating efficiency

Dimensions (LxWxH) (cm): 170 x 160 x 160

Weight (kg): 800

Technical Support

Hydraform provides full training for all of its machines, either through in-country training or at Hydraform's academy in Johannesburg, South Africa. During the courses all elements of production, maintenance and construction techniques are covered. Please contact the training department for further assistance and information, training@hydraform.com

Replacement Components

Hydraform offers a one year spares pack which includes 3x wear plates.

Lifecycle

6 month manufacturer warranty. Wearplates require replacement after 30,000 to 60,000 blocks.

Manufacturer Specified Performance Parameters

The M7 E380 is capable of producing around 1,500 blocks per 8 hour shift which is equivalent 40-50 m² of wall per day.

Vetted Performance Status

Full list of technical information and product evaluation available.

Safety

Unknown

Complementary Technical Systems

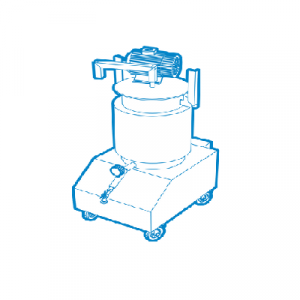

Recommend to be used with a 100 liter electric pan, Pan mixer, block cutter, block tester, 140 mm mold, 220 mm conduit mold, 220 mm capping mold and 3-phase power.

Academic Research and References

Patel, D.N., Pitroda, J.R., 2014, Techno economical development of low-cost interlocking paverblock by partially replacement of Portland pozzolana cement with used foundry sand waste, Journal of International Academic Research for Multidisciplinary. Volume 2, Issue 4, 607-615.

Ipinge, I., 2012, Durability of compressed stabilised earth blocks, Johannesburg, SA: University of Witwatersrand.

“Research work Report”, Wits University, accessed on February 29, 2024, https://wiredspace.wits.ac.za/server/api/core/bitstreams/d0bfe773-075a-4597-a654-4d0553905767/content

“Interlocking Soil Cement Blockmaking Machines”, Hydraform, accessed on February 29, 2024, https://www.hydraform.com/products/interlocking-soil-cement-blockmaking-machines/

Compliance with regulations

Unknown

Other Information

Hydraform warns that there are multiple lower quality Hydraform products being produced by various Chinese manufacturers.

Agriculture

February 26, 2024

Agriculture

February 27, 2024

Implemented by

California Institute of Earth Architecture (CalEarth)

Agriculture

March 6, 2024

Implemented by

ReMaterials

Agriculture

March 8, 2024

Implemented by

ByFusion

Agriculture

February 26, 2024

Implemented by

Grupo Ecoplasso

Agriculture

March 1, 2024

Agriculture

March 4, 2024

Implemented by

Makiga Engineering Services LTD

Agriculture

August 16, 2024

Implemented by

Green Pavers

Agriculture

March 13, 2024

Implemented by

Watershed Materials

Agriculture

March 14, 2024

Implemented by

Straw Resource Ltd.

Have thoughts on how we can improve?

Give Us Feedback