Agriculture

February 20, 2024

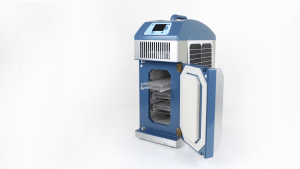

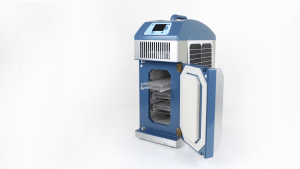

3rd Stone Design Stone Cold Solar

Read SolutionImplemented by

Stone Cold Systems

Updated on February 16, 2024

·Created on July 8, 2016

Cathy Sip Clip I.V Cannulas prevents accidental needle stick injury provided that general effective and safe working procedures and precautions are maintained during its use and disposal.

Cathy Sip Clip I.V Cannulas is a cost-effective device to prevent accidental needle stick injuries. It is designed with a safety mechanism activated automatically on withdrawal of needle post cannulation.

Cathy SiP CliP has an innovative plastic clip that automatically covers the blood contaminated needle tip as its removed from the IV Catheter to prevent any needle stick injury to the nurse or Doctor and any risk of infection of patient migrating to them.

Target SDGs

SDG 3: Good Health and Well-Being

Market Suggested Retail Price

$0.02

Target Users (Target Impact Group)

Small and Medium-sized Enterprises, Public Sector Agencies, NGOs

Distributors / Implementing Organizations

Sip Clip has partnered with Hindustan Syringes and Medical Devices Limited (HMD) , India's leading manufacturer of auto-disabling and single-use syringes for manufacturing and distribution of the Cathy Sip Clip I.V Cannulas. The product can be purchased on HMD's website.

Competitive Landscape

Direct competitors include PINNIX Light Safety Blood Lancet.

Regions

Europe, Middle East

Countries

India, United States

Manufacturing/Building Method

Mass-produced. HMD is having technical collaboration with M/s.Vigmed of Sweden to manufacture Safety I.V.Cannula. It is injection molded in one piece.

Intellectural Property Type

Patent

User Provision Model

Users will need to purchase directly from the manufacturer or through the manufacturer HMD's customer base of dealers, which is cited as being over 4000. This is based on Quid ProQuo whereby HMD will be OEM sub-contractor to Vigmed for the European market and Licensee for the Indian and Developing World market and sell under the HMD brand.

Distributions to Date Status

Unknown, but as of 2015 over 1.5million to Scandanavia alone.

Construction material

Needle: Siliconised electropolished, back cut bevelled stainless steel needle Catheter: Available in Volex™ polyurethane radio detectable, a proprietary pure polymer

Disposal Method

Standard sharps disposal methods should be used. The clip mechanism on the device prevents sharps injury.

Reuse prevention method

Unknown

Sterilization method

Unknown

Clinical application

IV Cannulation

Indispensable equipment for function (Y/N)

Yes, medication being administered via cannula

Maintenance or calibration required by user at time of use? (Y/N)

N

Design Specifications

Needle : Siliconised electropolished, back cut bevelled stainless steel needle. * With notch on 24G & 26G Cannula

Sip Clip : Sharps Injury Prevention Clip

Catherter : Available in Volex™ polyurethane radio detectable.

Needle hub : Allows blood flash back visualisation. Thumb rest for proper grip during insertion.

Blood stopper : The stopper has fine air vent to expedite blood flash back for enabling correct cannulation.

Luer lock cap : Closure to wing housing permits patient mobility when infusion temporarily discontinued.

Injection port cap : It facilitates extra medication and also prevents its back flow.

Blister package : I.V. Cannula is packed in rigid blister and sealed in peel open type medical grade paper.

Specifications such as gauge, extension of catheter (diameter and length), and water flow rate are listed on HMD's product page.

Technical Support

This is not applicable. However, the product page states a warning not to use this product if the pack has been previously opened or damaged.

Replacement Components

None, single-use product

Lifecycle

Single use only. Do not use if pack is previously opened or damaged.

Manufacturer Specified Performance Parameters

According to WHO, if safety cannula are made mandatory in hospitals, then around 80 per cent of all hospital staff can be saved from needle stick injuries. HMD sees this as a goal of their product.

Vetted Performance Status

Samples of Cathy +I.V. Cannula were given for clinical trial in leading hospitals and were found to be of satisfactory quality.

Safety

I.V. Cannula is packed in rigid blister and sealed in peel open type medical grade paper.

As the product is designed to guarantee a needle auto-protection safety mechanism, a functional Safety+ IV Cannula should be safe to use. No training should be required to deploy the safety mechanism, though experience with standard IV catheters is likely needed to understand proper usage. Additionally, improper syringe usage can still carry risks to the patient such as infection or embolism.

SIPCLIP prevents accidental needle stick injury provided that general effective and safe working procedures and precautions are maintained during its use and disposal.

Complementary Technical Systems

None

Academic Research and References

Chomnard, P., Jittaporn, C., Anucha, A., Somwang, D., 2005, Effectiveness of Education and Problem Solving Work Group on Nursing Practices to Prevent Needlestick and Sharp Injury. J Med Assoc Thai Vol, 88, pp. S115-S119.

Janine, J., Ella, H., Richard, D., 1990, Sharp object injuries in the hospital: Causes and strategies for prevention, American Journal of Infection Control. 18(4), pp.227-231/

Cathryn, M., 2008, Improved surveillance and mandated use of sharps with engineered sharp injury protections: a national call to action. Healthcare infection. 13(2), pp. 33-37.

Compliance with regulations

The official press release states that these products are manufactured as per ISO 9001, ISO 13485, and the European M.D.D. & US FDA standards.

Evaluation methods

Specific methods unknown, but samples of Cathy +I.V. Cannula were given for clinical trial in leading hospitals and were found to be of satisfactory quality.

Other Information

The flow rate for the catheter ranges between 15-200 ml/min dependent on gauge used. The specifications can be found on this website. For safety, standard sharps disposal methods should be used.

Agriculture

February 20, 2024

Implemented by

Stone Cold Systems

Agriculture

December 14, 2023

Implemented by

AFRIpads

Agriculture

December 2, 2024

Implemented by

BioLite

Agriculture

February 29, 2024

Implemented by

BRAC University

Agriculture

January 11, 2024

Implemented by

Caminos de Agua

Agriculture

March 11, 2024

Implemented by

Coolar

Agriculture

February 29, 2024

Implemented by

Every Shelter

Agriculture

August 14, 2024

Implemented by

Esther Mwangi, EsVendo

Agriculture

February 15, 2024

Implemented by

HemoCue

Agriculture

December 29, 2023

Implemented by

Vestergaard

Have thoughts on how we can improve?

Give Us Feedback