Agriculture

February 21, 2024

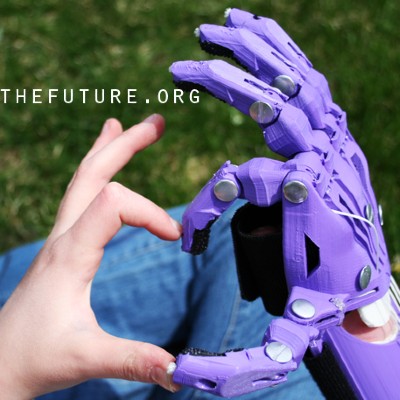

Adjustable prosthetic limb

Read SolutionImplemented by

NONSPEC

Updated on June 14, 2024

·Created on September 12, 2021

Online global community of 3D printers for making affordable prosthetic devices.

e-NABLE 3D printed prosthetic devices are designed by more than 30,000 volunteers from the e-NABLE community, a community created in 2013 to gather 3D printing enthusiasts who are interested in helping to make 3D printed hands for other people. In 2019, approximately 7,000 3D printed hands and arms were created and gifted to children and adults in need in over 100 countries around the world. Various designs can be found in their portfolio, and are constantly provided by the members of the community.

Target SDGs

SDG 3: Good Health and Well-Being

Market Suggested Retail Price

$35.00

Target Users (Target Impact Group)

Small and Medium-sized Enterprises, Public Sector Agencies, NGOs

Distributors / Implementing Organizations

Prosthetics are distributed by the volunteers of the community.

Competitive Landscape

Direct competitors include Adjustable prosthetic limb, CURE Prosthetics, and Polypropylene Prosthesis.

Regions

Worldwide

Manufacturing/Building Method

Prosthetics are manufactured and delivered by the volunteers of the community to the recipients, following a previously scheduled meeting. Assemble materials kits are provided by the e-NABLE Community.

Intellectural Property Type

Open-source

User Provision Model

Delivery from manufacturer (Volunteer).

Distributions to Date Status

7000 prosthesis delivered and gifted as of 2021.

Craftsmanship required

3D Printing

Patient satisfaction

Unknown

Patient compliance

Unknown

Comfort

Unknown

Materials

PLA, ABS, TPU, PETG, Velcro, Foam

Water resistant (yes/no)

Yes

Amputation level

Trans-Radial, Partial Hand

Weight (kg)

Unknown

Design Specifications

Devices must be affordable and light. The prosthetics should provide full range of motion, matching adduction and abduction degrees of typical human motion. Also, it must ensure patient comfort and is easy to put on. Designers wanted it to be durable, in order to withstand all operating conditions for 1-2 years. Finally, design should be reproducible, to be easily printed and improved in all parts of the world.

Technical Support

Provided by the volunteer and the e-NABLE Community.

Replacement Components

Assembly components can be found at the shop.

Lifecycle

Depends on the usage and the material selected. The hands hold up efficiently to activities like riding a bike, throwing a ball, swimming, and others. The Gripper Hand endures 60 pounds of pressure. The hands sustained minor damage, but survived. Additionally, the hands can also be printed in a variety of materials, including very durable nylon.

Manufacturer Specified Performance Parameters

e-NABLE prosthetics should be affordable, light, provide full range of motion, comfortable, durable, reproducible, and easy to put on.

Vetted Performance Status

A group of students has conducted initial impact testing by dropping the hands from a height of several stories. The hand resisted a 5 story fall, demonstrating its resilience and durability.

Safety

The e-NABLE Community recommends that children be at least 3 years old before wearing a device due to the choking hazards that small parts pose and so that children can have the chance to learn to do everyday things without a helper hand.

Complementary Technical Systems

User who wants to manufacture the prosthetics must have a 3-D printer.

Academic Research and References

Parry-Hill J., Shih P., Mankoff J., Ashbrook D., 2017, Understanding Volunteer AT Fabricators: Opportunities and Challenges in DIY-AT for Others in e-NABLE, Proceedings of the 2017 CHI Conference on Human Factors in Computing Systems, Association for Computing Machinery, pp. 6184–6194.

Kuehn BM., 2016, Clinicians Embrace 3D Printers to Solve Unique Clinical Challenges, JAMA, 315(4) pp.333–335.

Hawthorn P., Ashbrook D., 2017, Cyborg Pride: Self-Design in e-NABLE. Proceedings of the 19th International ACM SIGACCESS Conference on Computers and Accessibility. Association for Computing Machinery, pp. 422–426.

Parry-Hill, J., 2019, e-NABLE: DIY-AT Production in a Multi-Stakeholder System, Thesis, Rochester Institute of Technology.

Jacobs S., Schull J., White P., Bertucci A., 2016, e-NABLING education: Curricula and models for teaching students to print hands, IEEE Frontiers in Education Conference (FIE), pp. 1-4.

Schmidt R., Ratto M., 2015, 3D-printed prosthetics for the developing world. Association for Computing Machinery, 21(1).

Parry-Hill, J., Ashbrook D., 2016, Challenges and Opportunities in DFO-AT: A Study of e-NABLE.

Hofmann M., Burke J., Mankoff J., 2016, Clinical and Maker Perspectives on the Design of Assistive Technology with Rapid Prototyping Technologies, Proceedings of the 18th International ACM SIGACCESS Conference on Computers and Accessibility. Association for Computing Machinery, pp. 251–256.

Enabling the future, “Assembly Materials Kits”

Enabling the future, “Raptor Reloaded: Design and Intent“, 2014

Enabling the future, “Introducing e-NABLE’s Newest 3D Printed Hand Design – The Raptor!“, 2014

Enabling the future, “Impact Testing “The Beast!”“, 2014

The Brown and White, “Enabling the Future 3-D prints hands for children in need“, 2017

Compliance with regulations

These are experimental devices, and have not been reviewed by FDA. They come with a disclaimer of liability, and the community is actively looking for test pilots. Recipients whose residual limb is pressure tolerant, and does not require a highly customized device may well appreciate an e-NABLE device, it is always recommended to consult a doctor before considering an e-NABLE device.

Evaluation methods

Researchers are currently collecting data on 20 patients using e-NABLE hands to assess their effect on functional outcomes, as well as patients’ views on when the hands are useful and when they are not.

Other Information

3D Universe is a partner of the community.

Agriculture

February 21, 2024

Implemented by

NONSPEC

Agriculture

June 23, 2024

Implemented by

LoooP Creative Ltd

Agriculture

January 10, 2024

Implemented by

NRSRelief

Agriculture

December 31, 2023

Implemented by

Potential Energy

Agriculture

June 22, 2024

Implemented by

World Bicycle Relief

Agriculture

June 8, 2024

Implemented by

ClickMedix

Agriculture

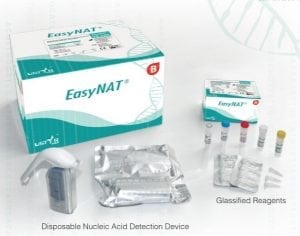

February 14, 2024

Implemented by

USTAR Biotechnologies (Hangzhou) LTD

Agriculture

January 8, 2024

Implemented by

Gadgil Lab, University of California Berkeley

Agriculture

December 3, 2024

Implemented by

Envirofit International

Agriculture

February 5, 2024

Implemented by

GE Healthcare

Have thoughts on how we can improve?

Give Us Feedback