Agriculture

February 26, 2024

Updated on February 29, 2024

·Created on July 8, 2017

EarthEnable is a floor made from locally found earth compressed and stabilized with a layer of oil.

EarthEnable is a floor made from locally found compressed earth and stabilized with a layer of oil. The floors are designed as a healthier alternative to dirt floors while being more affordable than concrete. The product is currently available on the market, but further product development is ongoing in order to improve the chemistry and provide more tiles and alternate colors.

Target SDGs

SDG 11: Sustainable Cities and Communities

SDG 12: Responsible Consumption and Production

Market Suggested Retail Price

$2.50

Target Users (Target Impact Group)

Household, Community, NGOs

Distributors / Implementing Organizations

Distributed by the manufacturer EarthEnable

Competitive Landscape

Direct competitors include Emergency Floor.

Countries

Kenya, Rwanda, Uganda

Manufacturing/Building Method

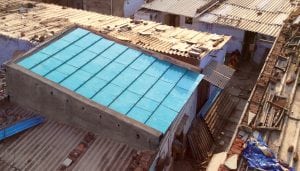

This product is mass-produced in Uganda and Rwanda. It is constructed on-site by trained masons from Earthenable. They train local Rwandans as masons to learn exactly how to create and install an earthen floor. Then, the masons can go out and become income-generating entrepreneurs utilizing their new skills. They also hire and train helpers for the masons, chemists, managers, administrative staff, and student interns.

Intellectural Property Type

Select Type

User Provision Model

Users can obtain the product and service from the manufacturer.

Distributions to Date Status

242,308 m² of flooring installed as of May 2021

Unit dimensions (cm)

Varies

Primary materials

Earth and Oil.

Complimentary materials

Unknown

Fire Resistance (hr)

Unknown

Thermal Insulation Capacity

Unknown

Compressive Strength (MPa)

Unknown

Suitable Climates

The floors are assumed to be suitable for all climates.

Design Specifications

An earthen floor is an ancient flooring technique that has been revived and modernized in recent years. Earthen floors are made of natural materials sourced locally (gravel, laterite, sand, clay, and water). Earthen floors utilize layers to make them as strong and resilient as possible.

The gravel layer is applied first, followed by the laterite layer, and then a clay/sand/laterite mix. All of these layers are compacted manually. Finally, the top layer is made of sand and clay, which is troweled flat. The floor is then sealed by a layer of drying oil that polymerizes as it dries to form a plastic-like resin on the floor.

In the US, linseed oil is traditionally used. However, given that linseed oil is expensive, not locally available in Rwanda, and slightly noxious, co-founder Rick Zuzow formulated an alternative oil that converts soya bean oil into a similarly performing drying oil free from noxious fumes and can be produced at a fraction of the cost.

Technical Support

Users can contact the manufacturer for technical support through their trained masons.

Replacement Components

To be replaced, the floor needs to be removed and redone either completely or in sections. More oil needs to be purchased from the manufacturer.

Lifecycle

EarthEnable anticipates that the floor will last 10-15 years and that revarnishing will be required every few years.

Customers can do the revarnishing by purchasing a varnish bottle and re-applying it according to Earth Enable's floor maintenance manual. Another option would be to contact EarthEnable to have one of their trained employees re-apply the varnish. This service would be free if within the 6 month warranty period, or otherwise would have a small fee.

Manufacturer Specified Performance Parameters

Manufacturer performance targets include health (ability to clean the floor), affordability, job creation, sustainability, and the scaleability of implementation.

Vetted Performance Status

None

Safety

No known safety hazards are related to this product.

Complementary Technical Systems

None

Academic Research and References

Covered in Ph.D. dissertation thesis:

Nuwagaba, H. M., 2020, “Opportunities for affordable construction in Uganda using locally available materials,” Doctoral dissertation, Massachusetts Institute of Technology.

Compliance with regulations

None

Other Information

This video shows the EarthEnable Flooring Process. The annual reports are also found on their website; the 2020 report can be found here.

“About us”, EarthEnable.org, accessed on February 29, 2024, https://earthenable.org/hm/about-us-2/

“Products”, EarthEnable.org, accessed on February 29, 2024, https://earthenable.org/hm/product/

Agriculture

February 26, 2024

Agriculture

February 27, 2024

Implemented by

California Institute of Earth Architecture (CalEarth)

Agriculture

March 6, 2024

Implemented by

ReMaterials

Agriculture

March 8, 2024

Implemented by

ByFusion

Agriculture

February 26, 2024

Implemented by

Grupo Ecoplasso

Agriculture

March 1, 2024

Agriculture

March 4, 2024

Implemented by

Makiga Engineering Services LTD

Agriculture

August 16, 2024

Implemented by

Green Pavers

Agriculture

March 13, 2024

Implemented by

Watershed Materials

Agriculture

March 14, 2024

Implemented by

Straw Resource Ltd.

Have thoughts on how we can improve?

Give Us Feedback