Agriculture

February 26, 2024

Updated on March 6, 2024

·Created on July 17, 2016

ModRoof is a custom manufactured and modular roofing system for houses.

ModRoof is an interlocking modular roofing system designed for low-income home owners. The commercialization of the product belongs to Pal Re Materials Pvt Ltd. The company is located in Changodar with operations in Ahmedabad, Mehsana, Vadodara, and Surat (India).

Target SDGs

SDG 11: Sustainable Cities and Communities

SDG 12: Responsible Consumption and Production

Market Suggested Retail Price

$3.00

Target Users (Target Impact Group)

Household

Distributors / Implementing Organizations

Pal Re Materials Pvt Ltd

Competitive Landscape

Direct competitors include Micro Concrete Roofing Tiles, HyPar Thin Shell Concrete Roof, and Corrugated Metal Panels.

Countries

India

Manufacturing/Building Method

Manufactured from recycled cardboard waste and natural fibers, the 0.5 x 0.5 m panels are installed side by side with a silicon sealant in between. Interview with manufacturer .The base structure of the roof system consists of wood or metal rafters separated ~0.5 m from each other.

Intellectural Property Type

Trademark

User Provision Model

Pal Re Materials Pvt Ltd manufactures, distributes, and installs the product. Users are offered enrollment into a micro-finance program to pay for the product.

Distributions to Date Status

An estimated 500 roof systems have been installed as of November 2019 (since January, 2014)

Unit dimensions (cm)

50 x 50 cm

Primary materials

Waste cardboard and coconut husk fibers

Complimentary materials

Adhesive, waterproofing additives, coating

Fire Resistance (hr)

Unknown

Thermal Insulation Capacity

0.28 K m2/W

Compressive Strength (MPa)

4.9 MPa (one panel can withstand approx 200 kg of point load)

Suitable Climates

Suitable in all climates

Design Specifications

The system consists of recycled packaging waste and waterproofing additives enclosed within rectangular 0.5 x 0.5 m with thickness ~0.05 m panels. With structural support, and silicon sealant, the system creates a watertight seal and a unified insulated roof surface. The interior insulation is cardboard waste, surrounded by a custom waterproofing coating. Circular clamps attach the panels to a typical metal tube frame roof structure. Interview with manufacturer

Technical Support

Pal Re Materials Pvt Ltd provides installation and support services.

Replacement Components

The system is composed of interlocking modules that can be individually replaced. The system uses conventional fasteners to attach the modules to the rafters (metal or wood screws depending of the type of material and metal angle braces).

Lifecycle

15 - 20 year estimated life span Interview with manufacturer

Manufacturer Specified Performance Parameters

ModRoof specifies the following performance targets:

1. An affordable, improved alternative to available roofing systems.

2. An insulated, fire resistant rain barrier to sustain a healthy living environment.

3. The system is removable, so if the family must move, the roof can be packed up and relocated.

Vetted Performance Status

The roofing panels have been tested for cross breaking strength, thermal conductivity, flammability, thermal stability, thermal shock, water absorption, and creep. Beyond these more formal tests performed by Nirma University, qualitative field tests and user reviews have also been done and several are available on ModRoof's Facebook page. Of the few installations, field tests and the user reviews have been positive. The system is strong such that the roof can support human occupancy - many families sleep on top of their roof during clear nights. A recent study performed by researchers at the Gujarat Institute of Desert Ecology, Indian Institute of Public Health, and the Mahila Housing Sewa Trust in India have compared the performance for thermal conductivity of a set of cool roof systems (including the ModRoof system) to conventional roofs made of tin, asbestos, cement sheets, and concrete slabs. The results of the study determined a reduction of 4.5 ºC in indoor temperature on roofs that used the ModRoof system compared to roofs that used tin, asbestos, cement sheets, and concrete slabs

Safety

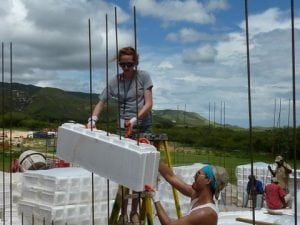

Installers of the roofing panels are subject to the general dangers of any construction site including working from heights and with sharp tools.

Complementary Technical Systems

The installation of the ModRoof system requires the complete removal of the existing roof. The roof panels are generally installed on a structure made of wood or metal rafters. Pal Re Materials Pvt Ltd has prototyped solar cells integrated into ModRoof panels.

Academic Research and References

Vellingiri, S., et al., 2020, Combating climate change-induced heat stress: Assessing cool roofs and its impact on the indoor ambient temperature of the households in the Urban slums of Ahmedabad. Indian Journal of Occupational and Environmental Medicine, 24, pp. 25-9.

“Ahmedabad: Making homes cooler with modular roofing”, India Times, accessed on March 6, 2024, http://timesofindia.indiatimes.com/articleshow/72090661.cms?utm_source=contentofinterest&utm_medium=text&utm_campaign=cppst

Ryce, Carolin, 2017, “How recycled roofs are transforming homes in slums” Innovators, BBC News, https://www.bbc.com/news/business-41722794

Williams, Adam, 2015, “ModRoof promises a safer shelter for low-income families”, New Atlas, https://newatlas.com/rematerials-roof/39239/

Compliance with regulations

Unknown

Evaluation methods

The Gurajat Institute of Desert Ecology, the Indian Institute of Public Health, and the Mahila Housing Sewa Trust have conducted a cross-sectional study in a set of households in the city of Ahmedabad in 2017 to understand the impact of cool roof solutions on the indoor ambient temperature. Researchers collected data through questionnaires to householders and measured temperature change using a relative humidity/temperature data logger. The ModRoof was one of the roof systems analyzed during this study.

Other Information

Social media: ModRoof Facebook Site

ModRoof Summary of tests

Agriculture

February 26, 2024

Agriculture

February 27, 2024

Implemented by

California Institute of Earth Architecture (CalEarth)

Agriculture

February 29, 2024

Implemented by

EarthEnable

Agriculture

February 29, 2024

Implemented by

EarthTek Inc.

Agriculture

March 8, 2024

Implemented by

ByFusion

Agriculture

March 4, 2024

Implemented by

Lazarian World Homes

Agriculture

March 4, 2024

Implemented by

Makiga Engineering Services LTD

Agriculture

August 16, 2024

Implemented by

Green Pavers

Agriculture

March 13, 2024

Implemented by

Watershed Materials

Agriculture

March 14, 2024

Implemented by

Hempitecture Inc.

Have thoughts on how we can improve?

Give Us Feedback

Seismic Design Category: Misspelling of “Seismic”; statement “dependent on building design schematics.” is awkward. “Dependent on structural engineering design per IBC or local building code”?