Agriculture

December 18, 2024

TINYTECH Portable Biogas Plant

Read SolutionImplemented by

Tinytech Plants

Updated on September 10, 2024

·Created on June 21, 2016

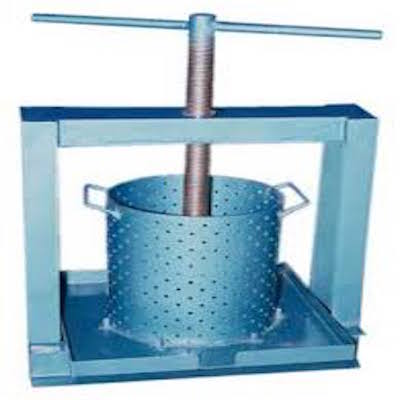

The TinyTech Mechanical Screw Press is a manual press that uses a screw fixture to expel oil from palm nut and fiber mixtures.

The TinyTech Mechanical Screw Press is a manually operated press with a screw fixture that is used to expel oil from palm fruit and fiber mixtures. The press is made up of a screw that pushes a plate into a cylindrical, perforated cage. The applied pressure causes oil to ooze out and it is collected by the bottom tray. There are two perforated cages that carry out the operation simultaneously to save time and avoid wastage.

This product is no longer available, as it was replaced by newer versions of an oil extraction machine.

Target SDGs

SDG 8: Decent Work and Economic Growth

Market Suggested Retail Price

$1,250.00

Target Users (Target Impact Group)

Small and Medium-sized Enterprises

Distributors / Implementing Organizations

Tinytech India, Exporters India, India Mart, and Tinytech Plants

Competitive Landscape

Direct competitors include Piteba Oil Expeller Press and Alvan Blanch Oil Expeller Press XP100-E.

Manufacturing/Building Method

The mechanical screw press units are assembled in Gujarat, IndiaInterview with representative

Intellectural Property Type

Open-source

User Provision Model

Users can obtain the Mechanical Screw Press from Exporters India, India Mart, and Tinytech Plants

Distributions to Date Status

50-80Interview with representative

Feedstock types

Palm nuts and fiber mixture

Volume of oil produced (L)

400-500 litres per dayInterview with representative

Capacity: Feedstock rate (kg/hr)

40-50 kg

Power source

Manual

Motor drive power (kW)

N/A

Design Specifications

The TinyTech Mechanical Screw Press has a perforated cylindrical cage in which the palm nuts can be fed. The mechanical screw press is operated by hand. By pressing the screw down, the pressure plate under the screw goes down into the perforated cylinder cage and presses the entire mass of palm fruits. Due to the pressure, palm oil is expelled through the small holes around the cylindrical surface. Oil is then collected into the utensils through the bottom tray. Two cylindrical perforated cages are provided with every press so that when one is under pressure, second cage is being filled up. Each cage can take about 40 to 50 kg of palm fruits per batch. About 25 to 30% palm oil is extracted.

Technical Support

Provided my manufacturerInterview with representative

Replacement Components

ScrewsInterview with representative

Lifecycle

Up to 40 yearsInterview with representative

Manufacturer Specified Performance Parameters

The Mechanical Screw Press is designed to saves time and avoid wastage in the production of palm oil

Vetted Performance Status

Unknown

Safety

There are no known safety hazards linked with the use of this product

Complementary Technical Systems

None

Academic Research and References

Karaj, S., and Müller, J., 2011, Optimizing mechanical oil extraction of Jatropha curcas L. seeds with respect to press capacity, oil recovery and energy efficiency. Industrial Crops and Products, 34(1), pp 1010-1016.

Compliance with regulations

Unknown

Agriculture

December 18, 2024

Implemented by

Tinytech Plants

Agriculture

September 10, 2024

Implemented by

Alvan Blanch

Agriculture

February 1, 2024

Implemented by

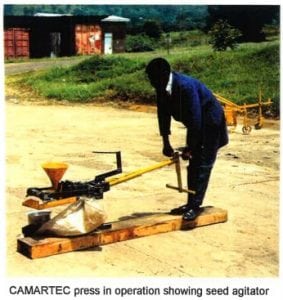

Centre for Agricultural Mechanization and Rural Technology (CAMARTEC)

Agriculture

February 1, 2024

Implemented by

Piteba

Agriculture

December 22, 2023

Implemented by

Engineers Without Borders USA

Agriculture

March 4, 2024

Implemented by

Makiga Engineering Services LTD

Agriculture

January 24, 2024

Implemented by

Bornay

Agriculture

January 20, 2024

Implemented by

Sustainable OneWorld Technologies C.I.C. (SOWTech)

Agriculture

February 6, 2024

Implemented by

MIT D-Lab

Agriculture

February 3, 2024

Implemented by

MATABI

Have thoughts on how we can improve?

Give Us Feedback