Agriculture

January 21, 2024

MBSA Biogas Plant

Read SolutionImplemented by

Mali Biocarburant SA

Updated on January 28, 2024

·Created on August 27, 2015

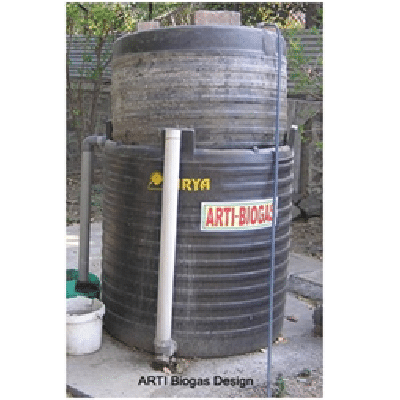

The ARTI is a domestic biodigester technology useful to generate gas primarly from cattle dung.

The ARTI biogas plant, a system developed by India’s Appropriate Rural Technologies (ARTI), converts food waste into methane-rich gas. The system is compact for urban use, suitable for both cities and farms, and designed to handle high-calorie feedstock such as leftovers, spoiled food and other kitchen waste, green leaves and other starches and sugars rather than manure or human waste.

Target SDGs

SDG 7: Affordable and Clean Energy

Market Suggested Retail Price

$137.00

Target Users (Target Impact Group)

Household

Distributors / Implementing Organizations

This product is implemented by ARTI.

Competitive Landscape

Direct competitors include SimGas Biogas Milk Chiller, Sistema Biobolsa, and Flexi Biogas BG5.

Countries

India

Manufacturing/Building Method

ARTI manufactures the digesters from off-the-shelf plastic storage tanks and third-party plumbing kits and biogas stoves supplied by Samuchit Enviro-Tech (SET) Pvt. Ltd. The installation time is about 3-4 hours and can be done by one person.

Intellectural Property Type

Open-source

User Provision Model

Users can obtain a system from ARTI or build the system themselves from off-the-shelf parts.

Distributions to Date Status

ARTI has installed 1000 systems since 2003 and installs 30-50 per month. The organization approximates that 2000 more have been built from DIY instructions.

Output energy product

Biogas

Average daily biogas production (m3/day)

250-500 g of gas per day for every 1-2 kg of feed

Description of waste source(s)

Starchy or sugary feedstock (waste grain flour, spoilt grain, overripe or misshapen fruit, nonedible seeds, fruits and rhizomes, green leaves, kitchen watse, leftover food, etc)

Waste input requirements (kg per hour or day)

1-1.5 kg/day of feedstock and 15 liters of water/day

Description of other input requirements

Unknown

Other input requirements (amount per hour)

Unknown

System dimensions (m)

1.4 m x 1.4 m x 2.5 m

Design Specifications

ARTI is made from two high-density polyethylene (HDPE) water tanks that are cut-down and adapted using a heat gun and HDPE piping. The size of the system is 1.4 m x 1.4 m x 2.5 m. One of the tanks is placed upside down in the upper part of the system to hold the gas, whilst the other one holds the slurry. The system also has an inlet and an overflow so that users can both add feedstock easily and remove digested residue. With the purpose of letting users employ the gas as a cooking fuel, a pipe is put in place to take the biogas to the kitchen.

Technical Support

Provided by the manufacturer.

Replacement Components

All components are replaceable and can be found off the shelf from third-party suppliers.

Lifecycle

Unknown

Manufacturer Specified Performance Parameters

Designer-specified performance targets include: compact, efficient, and fast.

Vetted Performance Status

Independent academic research performed in Tanzania found that 2 kg of kitchen produce is able to produce about 200 liters of biogas. It was also estimated that plants could be fed 5 kg/day producing 670 liters of biogas per day. The researchers recommended that additional customer service and training be available for the ARTI system due to frequent system failures resulting from a lack of education and assistance. Performance details can be found at Build-a-Biogas-Plant and Howtopedia.

Safety

Extreme caution is necessary when working with biogas. Adequate ventilation, appropriate precautions, good work practices, and adequate personal protective equipment will minimize the dangers associated with biogas. Wherever possible, digester-associated tasks and maintenance should be performed without anyone having to enter confined spaces, including pits.

Complementary Technical Systems

Complementary technical systems for biogas products include stoves, commercial burners, water heaters and gen-sets.

Academic Research and References

Voegeli, Y., Lohri, C., Kassenga, G., Baier, U., Zurbrugg, C., 2009, Technical and biological performance of the ARTI compact biogas plant for kitchen waste-case study from Tanzania. Twelfth International Waste Management and Landfill Symposium.

Lungkhimba, H.M., Karki, A.B., Shrestha, J.N., 2010, Biogas production from anaerobic digestion of biodegradable household wastes. Nepal Journal of Science and Technology, Vol. 11.

Austin, G., Morris, G., 2012, Biogas production in Africa. Bioenergy for sustainable development in Africa. Bioenergy for Sustainble Development in Africa, pp. 103 – 115.

Rahman, M., Paatero, J.V., 2012, A methodological approach for assessing potential of sustainable agricultural residues for electricity generation: South Asian perspective. Biomass and bioenergy, Vol. 47.

Karve, A.D., Karve, P., Kulkarni, G., 2005, A new compact biogas system based on sugary/starchy feedstock. Energy for sustainable development, Vol. 1.

Agrahari, R., Tiwari, G.N., 2013, The production of biogas using kitchen waste. International journal of energy science, Vol. 3.

Compliance with regulations

Unknown

Evaluation methods

The product was evaluated for methane content in the biogas by the Biogas Analyzer Gas Board-3200P. Independent laboratory and field analyses were carried out.

Other Information

The ARTI received an Ashden Award video.

A free do-it-yourself construction guide and video are available on the internet.

ARTI also offers other products like water tanks, fuel briquettes, improved cook stoves, plant tissue cultures and more.

More details on how to build the ARTI compact biogas digestor

Read more on ARTI biogas digester using waste foodstuffs

Biogas Plant by ARTI

Agriculture

January 21, 2024

Implemented by

Mali Biocarburant SA

Agriculture

December 18, 2024

Implemented by

Tinytech Plants

Agriculture

December 16, 2023

Implemented by

Green to Energy (G2E)

Agriculture

December 16, 2023

Implemented by

Husk Power Systems (HPS)

Agriculture

December 16, 2023

Implemented by

NETPRO Renewable Energy (India) Pvt Ltd

Agriculture

May 27, 2024

Implemented by

Development Technology Workshop

Agriculture

December 17, 2024

Implemented by

Biogas International Limited

Agriculture

May 27, 2024

Implemented by

Montals Engineering

Agriculture

December 19, 2024

Implemented by

Green Heat

Agriculture

September 18, 2024

Implemented by

Alvan Blanch

Have thoughts on how we can improve?

Give Us Feedback