Agriculture

December 16, 2023

G2E Biomass Gasification Plant

Read SolutionImplemented by

Green to Energy (G2E)

Updated on December 16, 2023

·Created on June 5, 2014

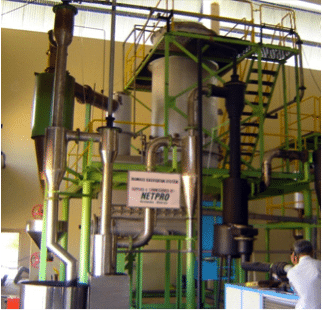

Fabricated by Netpro and distributed by DESI Power in India, this is a Biomass Gasification Power Plan with an output capacity from 20 kW to 1.2 MW.

The Biomass Gasification Power Plant is a clean energy technology that has an output capacity of 20 kW to 1.2 MW. As of September 2018, this is a discontinued product from DESI Power.

Target SDGs

SDG 7: Affordable and Clean Energy

Market Suggested Retail Price

$200,000.00

Target Users (Target Impact Group)

Household, Community, Small and Medium-sized Enterprises

Distributors / Implementing Organizations

This product has been implemented by DESI Power, DASAG Energy Engineering, Government of India and TARA (Technology for Action and Rural Advancement), Village EmPower Partnership Programme and Smart Power for Environmentally and Economically Sound Development (SPEED).

Competitive Landscape

Direct competitors include Flexi Biogas BG5, SimGas GesiShamba, HPS Biomass Gasification Power Plant, and TINYTECH Portable Biogas Plant.

Countries

India

Manufacturing/Building Method

The product is designed and built individually depending on demand and fabricated by Netpro.

Intellectural Property Type

Select Type

User Provision Model

The product has been discontinued as of 2018, but was previously available directly through DESI/NetPro.

Distributions to Date Status

As of August 29, 2012, 14 had been distributed.

Power rating (W or kW)

20-1200 kW

Available energy type (mechanical, thermal, electrical)

Electrical

Description of biomass source(s)

Animal waste and wood, although the woody biomass must be 60 x 20 x 20 mm or less in dimension with no more than a 15% moisture content. To date, the system mainly uses Dhaincha, Ipomea and firewood for operation.

Biomass input requirements (kg per hour)

1 kg per unit of electricity

Description of other input requirements

Unknown

Other input requirements (amount per hour)

Unknown

Combustor type

Gasifier

Biomass conversion efficiency (%)

Unknown

Particulate matter and CO emissions (ppm)

Unknown

System dimensions (m)

Unknown

Design Specifications

The NETPRO biomass plant is a biomass gasification system. Preferred biomass species include ipomia, casurina, wood chips rice husk briquettes. The biomass dimensions must be 6 x 2 x 2 cm or less. The plant’s rated capacity is 20 kW to 1.2 MW. The biomass requirement is 1 kg per unit of electricity.

Technical Support

Technical support is provided by Netpro. These services include:

• Supervision for Construction and Erection

• Support for Plant Commissioning

• Training of employees for Operation and Maintenance

• Guidance for Energy Plantation

Replacement Components

Replacement components available through Netpro. As DESI is involved throughout the system operation it is possible that parts can be outsourced from elsewhere. Report from CDF claims replacement parts are outsourced exclusively from NetPro which can delay repair/service.

Lifecycle

Unknown

Manufacturer Specified Performance Parameters

Designer-specified performance targets include: affordable and decentralized.

Vetted Performance Status

A 2010 CDF Report conducted a comparison of DESI and Husk Power. They conclude that both systems/ organizations have advantages as the focus on slightly different clients, financing, structure and type of biomass used. The biggest comparison financially is that the minimum monthly payment required for electricity from DESI Power plant is approximately Rs. 100 - In contrast, a household in a village where Husk Power Systems operates can get the same amount of electricity for half that price. It was also found in 2007 that the avg. DESI power raw material consumption/hour was 50-70 kg (for 75 kWe plant), and the capital costs for a plant of 50 KWe capacity is $1400/KW. Other reports/organizations (Rockefeller and Gates Foundation) determined the purchase price capacity of the system, which was $1600/KW for a 25 KWe system, $1400/KW for a 50 KWe system, and $900/KW for a 110-450 KWe system.

Safety

There can be dangers operating a biogas systems during the operation of machinery, the event of a malfunction (voltage, handling Hydrogen and Carbon Monoxide), and in handing residue/by-products.

Complementary Technical Systems

The system can be paired with PV and/or wind to optimize energy production.

Academic Research and References

Kohli, S. and Ravi M.R., 2003, Biomass gasification for rural electrification: prospects and challenges. SESI Journal, Volume 13.

F. G. M. Ermers, 2007, Biomass gasifier applications in rural India -Past experiences and future plans reviewed. Master thesis for Technology & Policy, Faculty of Technology Management University of Technology, Eindhoven, The Netherlands.

Institute for Financial Management and Research (IFMR), and Centre for Development Finance., 2010, Review of Empowering Villages: A Comparative Analysis of DESI Power and Husk Power Systems: Small-Scale Biomass Power Generators in India. India: Institute for Financial Management and Research (IFMR).

Services Offered. n.d. www.desipower.com.

Roach, Mary, and Charlotte Ward. 2011. Review of Harnessing the Full Potential of Mobile for Off-Grid Energy. Gsma. GSMA, IFC.

Binns, Patrick. n.d. Review of Sowing the Seeds of Prosperity: Developing Bioenergy Technology to Alleviate Smallholder Farmer Poverty. Globalbioenergy.org. Bill?&?Melinda?Gates?Foundation.

Compliance with regulations

Unknown

Evaluation methods

Evaluation method by (2011) CDF Report which examined DESI and Husk Power looked at: Technology Type, Area and End-User profile, Cost of Establishment and Operations, Feedstock Supply Chain, Distribution and Revenue Collection, Pricing Strategy and Management Team and Man Power.

In terms of technology development/testing it appears the evaluation is done through NetPro and DESI. The evaluation methods focus on the financial analysis of power outputs, hours of electricity provided and entrepreneurial opportunities. The report by Gates Foundation refers to an analysis by DESI, which compared the installed cost of locally produced power from a biogasification system to centrally produced power.

Other Information

Additional performance data here.

Agriculture

December 16, 2023

Implemented by

Green to Energy (G2E)

Agriculture

December 16, 2023

Implemented by

Husk Power Systems (HPS)

Agriculture

November 30, 2024

Agriculture

January 28, 2024

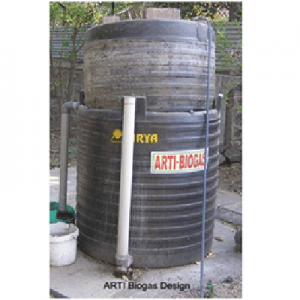

Implemented by

Appropriate Rural Technology Institute (ARTI)

Agriculture

January 21, 2024

Implemented by

Mali Biocarburant SA

Agriculture

December 18, 2024

Implemented by

Tinytech Plants

Agriculture

January 18, 2024

Implemented by

Agua Clara LLC

Agriculture

September 18, 2024

Implemented by

Alvan Blanch

Agriculture

June 24, 2024

Implemented by

Angaza

Agriculture

December 7, 2024

Implemented by

Azuri Technologies

Have thoughts on how we can improve?

Give Us Feedback