Agriculture

December 16, 2023

HPS Biomass Gasification Power Plant

Read SolutionImplemented by

Husk Power Systems (HPS)

Updated on December 16, 2023

·Created on June 28, 2016

G2E transforms biomass waste and provides a gasification technology solution to industrial and rural communities across Mexico.

G2E provides a gasification technology solution for rural communities, in the form of biomass gasification plants which have a generation capacity of 15 kW up to 2 MW.

The purpose of the biomass gasification plant is not only to produce electrical energy but to polygenerate and produce electricity, heat and gas. During the power generation process, there is the possibility to produce biochar as an alternate product. Biochar is composed of 80% carbon and can be used for soil enhancement. Biochar is a way to fix CO2 in soil for hundreds of years, therefore it is a carbon-negative energy. (Watch an introduction video to biochar.)

G2E adapts the solution to the customers’ needs and to the biomass that is available. G2E has a biomass gasification demonstration center in Mexico City, with 4 gasifiers with different features to evaluate/compare technological and energy performance of different biomass feedstocks and technology modifications.

Green to Energy is located in Mexico City, Mexico.

Target SDGs

SDG 7: Affordable and Clean Energy

Market Suggested Retail Price

$100,000.00

Target Users (Target Impact Group)

Community, Small and Medium-sized Enterprises

Distributors / Implementing Organizations

G2E (Green To Energy)

Competitive Landscape

Direct competitors include Green Heat Biogas Digester, Nopalimex, and ARTI Biogas Plant.

Countries

Mexico

Manufacturing/Building Method

The technology is being produced in Asia. For the demonstration center, the four gasifiers were manufactured in India (2), China (1) and the United States.

G2E is a licensed distributor for all the biomass plants. However, G2E improves the plants using their expertise, making possible the use of various types of residual biomass. Interview with representative

As of July 2016, G2E plans to produce products in Mexico. Interview with representative

Intellectural Property Type

Patent

User Provision Model

Users can contact G2E to get information, advice, and support.

For rural areas, G2E relies on subsidies to install the product. For businesses, they evaluate the point of profit of the technology, depending on the type of plant and biomass used. Interview with representative

Distributions to Date Status

As of July 2016, there are three projects in Mexico. Customers include three corn seed producers and one tequila distillery.

Power rating (W or kW)

15 kW to 2 MW

Available energy type (mechanical, thermal, electrical)

Mechanical, thermal, electrical + biochar (to store C02)

Description of biomass source(s)

All types of residual biomass

Biomass input requirements (kg per hour)

20 kg to 2.2 tons

Description of other input requirements

Unknown

Other input requirements (amount per hour)

Unknown

Combustor type

Fixed bed downdraft gasifier connected to filtering systems for the production of electricity (they can be configured without the filters for a thermal approach)

Biomass conversion efficiency (%)

80-85%

Particulate matter and CO emissions (ppm)

Not tested

System dimensions (m)

Unknown

Design Specifications

The biomass demonstration center consists of 4 gasifiers with different primary fuel and technology modifications. Two of them are manufactured in India: combo-40 and PG-45. The center also carries auxiliary equipment for the preparation of biomass, consisting of pre-treatment equipment including driers and compactors for briquetting as well as water scrubbing for the cleaning of synthesis gases (one of the gasification technologies) and a motor with internal combustion, loaned by the company Cummins.

Among the several types of biomass residues tested, corn cob and coconut have proven to be more efficient. They do not require pre-treatment and produce high-quality gas that does not need scrubbing. Interview with representative

Technical Support

G2E provides support to the users Interview with representative

Replacement Components

G2E provides replacement parts Interview with representative

Manufacturer Specified Performance Parameters

Designer specified performance targets include affordable and modular.

Vetted Performance Status

Safety

There are some potential dangers operating the biomass plant: noise, hazardous waste material disposal, voltage.

Complementary Technical Systems

None

Academic Research and References

None

Compliance with regulations

None

Evaluation methods

Testing was completed by the manufacturer at their demonstration center in Mexico City to determine conversion efficiency of different materials.

Other Information

G2E receives funding from Universidad Nacional Autónoma de México (UNAM) and SAGARPA, Secretaría de Agricultura.

The offices and warehouses were built based on containers and recycled material, with the idea of matching the use of "material" of little value. The office has a classroom-auditorium for dissemination and training.

More photos of Biochar, used to capture CO2:

[caption id="attachment_19818" align="alignnone" width="300"] Biochar[/caption]

Biochar[/caption]

[caption id="attachment_19819" align="alignnone" width="231"] Biochar[/caption]

Biochar[/caption]

Agriculture

December 16, 2023

Implemented by

Husk Power Systems (HPS)

Agriculture

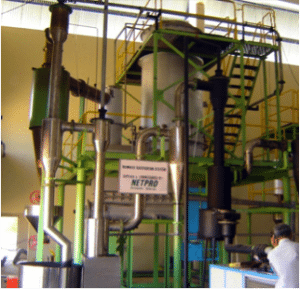

December 16, 2023

Implemented by

NETPRO Renewable Energy (India) Pvt Ltd

Agriculture

November 30, 2024

Agriculture

January 28, 2024

Implemented by

Appropriate Rural Technology Institute (ARTI)

Agriculture

January 21, 2024

Implemented by

Mali Biocarburant SA

Agriculture

December 18, 2024

Implemented by

Tinytech Plants

Agriculture

January 18, 2024

Implemented by

Agua Clara LLC

Agriculture

September 18, 2024

Implemented by

Alvan Blanch

Agriculture

January 20, 2024

Implemented by

Adventist Development and Relief Agency (ADRA)

Agriculture

December 31, 2023

Implemented by

Potential Energy

Have thoughts on how we can improve?

Give Us Feedback