Agriculture

December 11, 2024

A-Light S

Read SolutionImplemented by

Ambros Huber

Updated on December 23, 2024

·Created on December 6, 2022

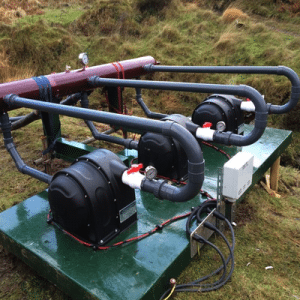

BioQUBEs are small scale anaerobic digesters (biogas digesters) providing a compact solution to process smaller volumes of feedstocks and wastes on site.

BioQUBEs are small scale anaerobic digesters (biogas digesters) providing a compact solution to process smaller volumes of feedstocks and wastes on site. The systems can be configured for each site to allow multiple digesters running from a single feed system along with biogas storage, energy generation and digestate pasteurization.

The system includes several components from flexible piping, large capacity reservoirs made from plastics to shipping containers. According to the manufacturer, each system comprises 20 or 40 foot shipping containers with different numbers of modules to make up the required unit processing size. Differing feedstocks have different biogas yielding values. For example, one ton of cow slurry yields 21 m3 of biogas compared to one ton of fatty food waste which yields 320 m3 of biogas.

Target SDGs

SDG 7: Affordable and Clean Energy

SDG 8: Decent Work and Economic Growth

Target Users (Target Impact Group)

Household, Small and Medium-sized Enterprises

Distributors / Implementing Organizations

QUBE Renewables Ltd

Competitive Landscape

Direct competitors include Sistema Biobolsa.

Agriculture

December 11, 2024

Implemented by

Ambros Huber

Agriculture

June 23, 2024

Implemented by

Bajaj

Agriculture

December 2, 2024

Implemented by

EcoInnovation Ltd. (Powerspout)

Agriculture

December 2, 2024

Implemented by

Mobile Hydro

Agriculture

January 22, 2024

Implemented by

Sistema.bio

Agriculture

December 10, 2024

Implemented by

Orb Energy

Agriculture

December 10, 2024

Implemented by

Orb Energy

Agriculture

December 18, 2024

Implemented by

Tinytech Plants

Agriculture

December 7, 2024

Implemented by

Shamba Technologies Ltd.

Agriculture

December 11, 2024

Implemented by

SolarNow

Have thoughts on how we can improve?

Give Us Feedback