Agriculture

January 17, 2024

Compartment Bag Test (CBT) Kit

Read SolutionImplemented by

Aquagenx

Updated on February 29, 2024

·Created on June 7, 2016

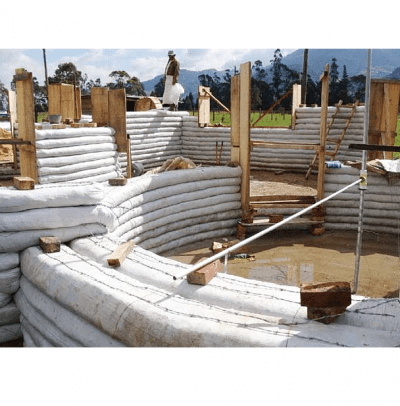

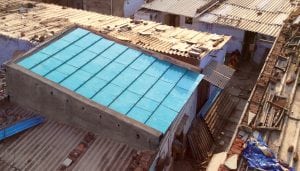

Earthbag, also known as superadobe or soilbag, is a structural construction material used in natural building that requires easily found resources. It is mainly made of polymer bags (burlap sack) filled with soil, that is, a mixture of clay, silt, and san

Earthbag construction is a construction material that is both strong and can promote quickly building. It is a natural building technique that evolved from historic military bunker construction techniques and temporary flood-control dike building methods. The technique requires very basic construction materials: sturdy sacks, filled with inorganic material usually available on site. Standard earthbag fill material has internal stability. Either moist subsoil that contains enough clay to become cohesive when tamped or angular gravel or crushed volcanic rock is used. (Sandbag structures with sand fills are an alternative technology and require very different construction details). Walls are gradually built up by laying the bags in courses — forming a staggered pattern similar to bricklaying.

Target users are Any person, community, or organization that wants to construct a low-cost and low-impact structure out of a easily available material: soil.

Target SDGs

SDG 11: Sustainable Cities and Communities

SDG 12: Responsible Consumption and Production

Market Suggested Retail Price

$16.00

Target Users (Target Impact Group)

Household, Community, NGOs

Distributors / Implementing Organizations

Varies. While some organizations have marketed and commercialized earthen bag construction manuals and equipment, others have been developing free construction manuals.

Competitive Landscape

Direct competitors include Bottle Bricks and AECT Impact 2001A Compressed Earth Block Machine.

Regions

Worldwide

Manufacturing/Building Method

Earthbag as a construction material has been used all over the world in different countries and several construction sites. Specially, in low-income regions and post disaster affected areas. The earth used in the bags and the rubble for the foundation can be locally found. Polypropylene bags, barbed wire, rebar, sand and cement have to be purchased.

Intellectural Property Type

Patent

User Provision Model

Users can obtain this product by constructing it themselves. Some organizations like CalEarth and Good Earth Global commercialize earthbags construction manuals, equipment, and building designs. There are also other organizations that offer free construction manuals. Earthbag can be produced anywhere the necessary resources are available. These are basically bags (burlap or polypropylene sacks) and soil.

Distributions to Date Status

The exact number is unknown, however, earthbag construction material is a very widespread technique, used all around the globe.

Unit dimensions (cm)

The bag can have different sizes according to the project. For example, they can go in woven polypropylene bags of 46 cm x 76 cm

Primary materials

Polymer bags, sand

Complimentary materials

Clay, silt

Thermal Insulation Capacity

Ranging from R-15 to R-25

Compressive Strength (MPa)

According to the structural analysis of earthbag developed by Nikul Vadgama (2010), for a vertically loaded earthbag the compressive strength is dependent upon the tensile strength of the bag material and the friction angle of the soil. However, the author points out some important guidelines that should be adopted when using this material, such as:

Finally, we can conclude that the vertical loads which an earthbag has to resist in a one storey house are unlikely to reach the vertical load capacity of the earthbag.

Suitable Climates

Dry, Tropical, Moderate

Design Specifications

Earthbag construction is made by filling polymer bags with locally available earth. Even though local earth is used, it's very important to ensure the correct soil mixture to allow the earth to be compacted as it is tamped inside the bags. Stabilizers such as lime or portland cement can also be added to improve the resistance of construction. The bags are generally made from polypropylene because it is a strong, durable, and semi-permeable material. The filled bags are laid in their desired form and each layer is tamped before laying the next layer. Barbed wire is placed between the layers to hold the bags at the proper position, and prevent the wall to get out of plumb. There are several online resources that give very detailed instructions on how to build earthbag constructions.

Technical Support

The building can be maintained by local labour with Earth Building construction experience.

Replacement Components

N/A

Lifecycle

Built and maintained properly, an Earthbag building should stand for centuries

Manufacturer Specified Performance Parameters

There are many different manufacturers of earthbag constructions in the market. But, in general, earthbag is commonly described as an low-cost and low-impact technology with great thermal insulation and earthquake resistance.

Vetted Performance Status

Tests results available in the studies provided by testing organizations are related to soil mixtures used, this is, there are a wide range of results using different mixtures. As every soil is different from place to place the most important part of construction is to find the correct soil mixture. Besides that, tests concluded that earthbags have a much lower lateral strength than compressive strength, while seismic resistance is to be tested even if it suggests that earthbags have great resistance to earthquakes.

Safety

Builders should wear appropriate protective equipment such as hardhats, gloves and safety glasses while working to protect against physical injury commonly associated with heavy construction. Earth bag construction does not require the operation of any large machinery.

Complementary Technical Systems

On exposed walls, many suggest to use a protective topcoat, embed tile or pebbles in earth plaster, use lime plaster or cement plaster on sandy earthbag fill.

Academic Research and References

Canadell, S., Blanco, A., Cavalaro, S. H.P., 2016, Comprehensive design method for earthbag and superadobe structures, Materials & Design. V. 96, Pages 270-282

Croft, C., 2011, Structural resistance of earthbag housing subject to horizontal loading. Master’s thesis, The University of Bath.

Daigle, B., 2008, Earthbag housing: structural behavior and applicability in developing countries. Master’s thesis, Queen’s University, Canada.

Kaki H, and Kiffmeyer D. (2004). Earthbag Building: The Tools, Tricks and Techniques (1st Edition). British Columbia, Canada: New Society Publishers.

Malik, A., 2013, Structural analysis of earthbag systems. Master’s thesis, Thayer School of Engineering at Dartmouth.

Tantono, S. F. (2008). The mechanical behavior of a soilbag under vertical compression . Master’s Thesis, Technischen Universität Graz, Graz, Austria.

Vadgama, N., 2010, A Material and Structural Analysis of Earthbag Housing. Dissertation (M.Eng.). University of Bath, Department of Architecture and Civil Engineering.

Zhaoa, Z. Lub, Q. Jiangc, X. , 2015, An Energy Efficient Building System Using Natural Resources–Superadobe System Research. Procedia Engineering Volume 121, Pages 1179-1185

Trigo Salas, A., 2015, Estudio del comportamiento estructural de construcciones de tierra:La técnica constructiva Earthbag, Universitat Politècnica de Catalunya

Stouter, P., Soil Tests for Earthbags Page 11

Compliance with regulations

None

Evaluation methods

Earthbag are mostly tested by compression strength, lateral load tests and soil mixture (clay, sand, gravel) parameters.

Other Information

This video gives general information about earthbag construction: Cal-Earth Sustainable Architecture

Agriculture

January 17, 2024

Implemented by

Aquagenx

Agriculture

November 22, 2023

Implemented by

Laerdal Global Health

Agriculture

February 5, 2024

Implemented by

Vestergaard

Agriculture

September 27, 2024

Implemented by

Teheca Limited

Agriculture

December 19, 2023

Implemented by

Aqua-Aero WaterSystems BV (AAWS)

Agriculture

March 6, 2024

Implemented by

ReMaterials

Agriculture

February 26, 2024

Implemented by

Grupo Ecoplasso

Agriculture

March 1, 2024

Agriculture

June 30, 2024

Implemented by

Lifeway Solar

Agriculture

March 14, 2024

Implemented by

Straw Resource Ltd.

Have thoughts on how we can improve?

Give Us Feedback