Agriculture

February 27, 2024

CalEarth SuperAdobe

Read SolutionImplemented by

California Institute of Earth Architecture (CalEarth)

Updated on February 29, 2024

·Created on May 27, 2016

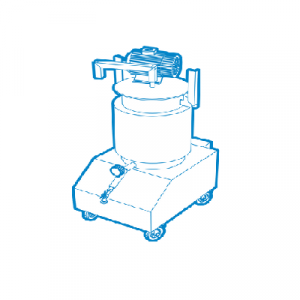

The BLM-12-8 series by Earthtek Inc. are three gasoline-fueled, manual and automatic brick-making machines with a single axle for highway transportation.

The BLM-12-8M by Earthtek Inc. is a manually controlled brick-making machine with a single axle for highway transportation. It can produce up to 2 bricks per minute. Its 6HP engine is fuelled with gasoline and can generate a pressure of 10MPa on the bricks.

Any “owner-builder” looking to manually self-construct a block structure.

Target users are Any “owner-builder” looking to manually self-construct a block structure.

Target SDGs

SDG 11: Sustainable Cities and Communities

SDG 12: Responsible Consumption and Production

Market Suggested Retail Price

$9,000.00

Target Users (Target Impact Group)

Household

Distributors / Implementing Organizations

The manufacturer requires potential customers to contact them to receive a quotation for the product.

Competitive Landscape

Direct competitors include Hydraform M9, AECT Impact 2001A Compressed Earth Block Machine, and Terrabric 2B.

Regions

Worldwide

Manufacturing/Building Method

Machines are built to order. The way that the earth construction and these machines work are introduced in this video.

Intellectural Property Type

Trade Secret

User Provision Model

A user can contact EarthTek Inc. to receive a quote or purchase the product. The unit can be crated economically for shipping. Interview with manufacturer

Distributions to Date Status

Approximately 200 units have been distributed by 2019. Interview with manufacturer

System Dimensions

Unknown

Portability (yes/no)

Yes

Raw materials used

Earth, Sand, Cement

Recommended water content (ratio)

6 – 10

Induced pressure (Mpa)

10

Power source

Gasoline fueled engine with manual controls.

And Gas fueled engine for the automatic control.

Finished unit dimensions

10 x 20 (adjustable) x 30 cm

Rate of production (units/hour)

~240

Curation duration (days)

Unknown.

Suitable climate

Not suitable for cold climates unless necessary vapor barriers and insulation can be added. On their own, ISSBs and CEBs do not hold up well to freeze/thaw cycles and have a low thermal insulation capacity.

Design Specifications

Design specifications::

Technical Support

The manufacturer offers consultation, training, and project management by contract and will train a customer to use the machine if they come to their facility in New Mexico, USA. A trained general technician can most likely repair the product.

Replacement Components

Spare tires, wheels, and axles are available with purchase.

Lifecycle

The life span of the machine is directly proportionate to the abrasiveness of the dirt used for compression. EarthTek estimates 50,000 - 500,000 blocks/life. All machines have a 1-year warranty.

Manufacturer Specified Performance Parameters

Performance expectations: Reliable, inexpensive engines, simple hydraulic and control systems, able to use a wide variety of soils to build homes, barns, storage sheds, fences, retaining walls, and more.

Vetted Performance Status

The only vetting performed is through customer experience and feedback.Interview with manufacturer

Safety

Blocks require specific material amounts and ratios to ensure proper strength and durability values. Water content, clay content, and sand content are important values that need to be evaluated during construction to avoid accidental failure of the structure.

Complementary Technical Systems

A 1.5 or 3-meter gravity conveyor belt can be purchased with the machine.

Academic Research and References

“BLM-12-8M”, EarthTek Inc., accessed on February 29, 2024, http://www.adobemachine.com/machines/blm/12-8m.htm

“Machines”, EarthTek Inc., accessed on February 29, 2024, http://www.adobemachine.com/machines/blms8eries.htm

Compliance with regulations

Unknown

Agriculture

February 27, 2024

Implemented by

California Institute of Earth Architecture (CalEarth)

Agriculture

March 6, 2024

Implemented by

ReMaterials

Agriculture

March 8, 2024

Implemented by

ByFusion

Agriculture

February 26, 2024

Implemented by

Grupo Ecoplasso

Agriculture

March 1, 2024

Agriculture

March 4, 2024

Implemented by

Makiga Engineering Services LTD

Agriculture

August 16, 2024

Implemented by

Green Pavers

Agriculture

March 13, 2024

Implemented by

Watershed Materials

Agriculture

March 14, 2024

Implemented by

Hempitecture Inc.

Agriculture

March 14, 2024

Implemented by

Straw Resource Ltd.

Have thoughts on how we can improve?

Give Us Feedback